-

Posts

570 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by tundrayeti

-

-

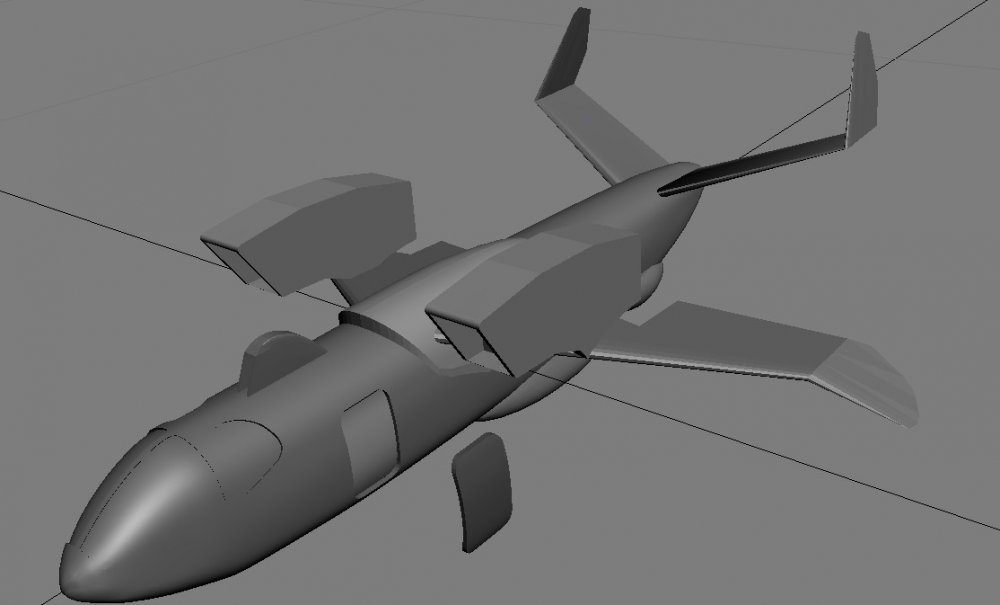

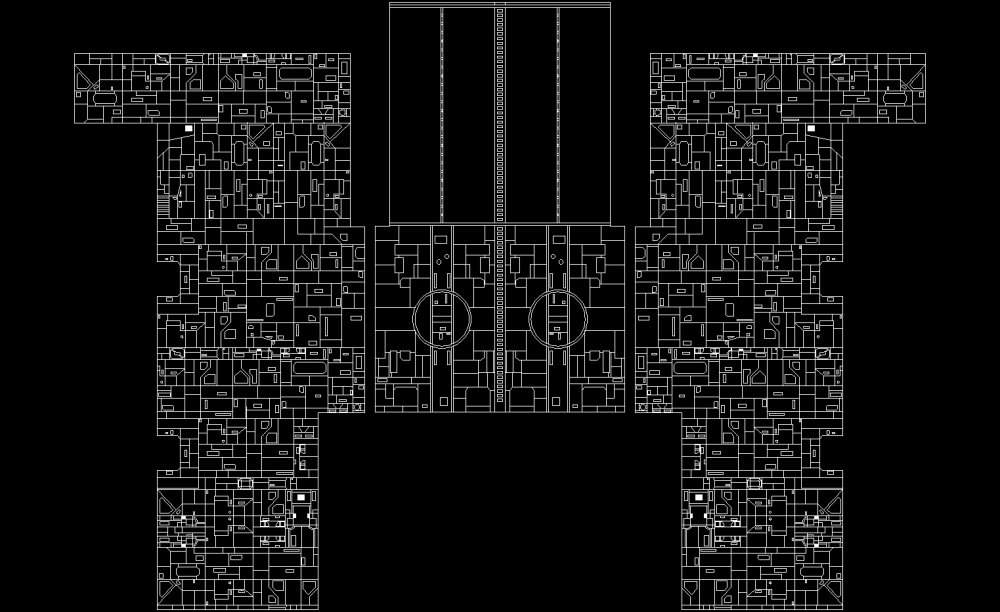

Well I looked around for something interesting. I like the Kotobukiya chain bases, bought a few but i wanted to do something big. I managed to get my hands on a few of the 1/100 scale macross armored factories, but i wanted to incorporate them all. I have a friend who owns a sign business and one of his toys was a CNC router to do engraved signs. my solution, design my own wall and floors and just have the engraver do the work for me. I went out and bought plastic panels for about $40 buck and designed my own layout. I have a picture of my floor layout. I am having them routed now I will post pictures when I get them back. I did my layout in autocad let me know what you think. (just to give you and idea this thing will take up a 6 ft by 4 foot space.) I am also including some snapshots of the 3d SC-27 stargoose that i plan to print out with a 3d printer. I have it scaled to 1/100, the thing will be over a foot long. just some extras i am adding.

-

I love the paint scheme on the vf-11 jolly roger! sweet!!!

-

I am also in the process of building my own hangar in 1/100 scale. I must say i like some of what you have done! very nice work ICE! My wife got me some of the toynami 1/100 scale valks and I was hooked. So i had to build something to put them all in. I am currently working on some 1/100 scale models to go with them let me know if you are interested. I am also making my own customized panels. But it's always nice to see that other people have the same ideas.

-

All i can do is echo everyone else and say.. WOW!

-

If you do decide to go with CG check out Blender. It's freeware and there are tons of stuff on the internet as far as tutorials and advice. Not that I have anything against kitbashing I love both. Just some info you might find helpful

-

Announcing Macross Aria: a CGI fan film project

tundrayeti replied to chillyche's topic in Fan Works

If you are still looking for 3d modellers, Let me know -

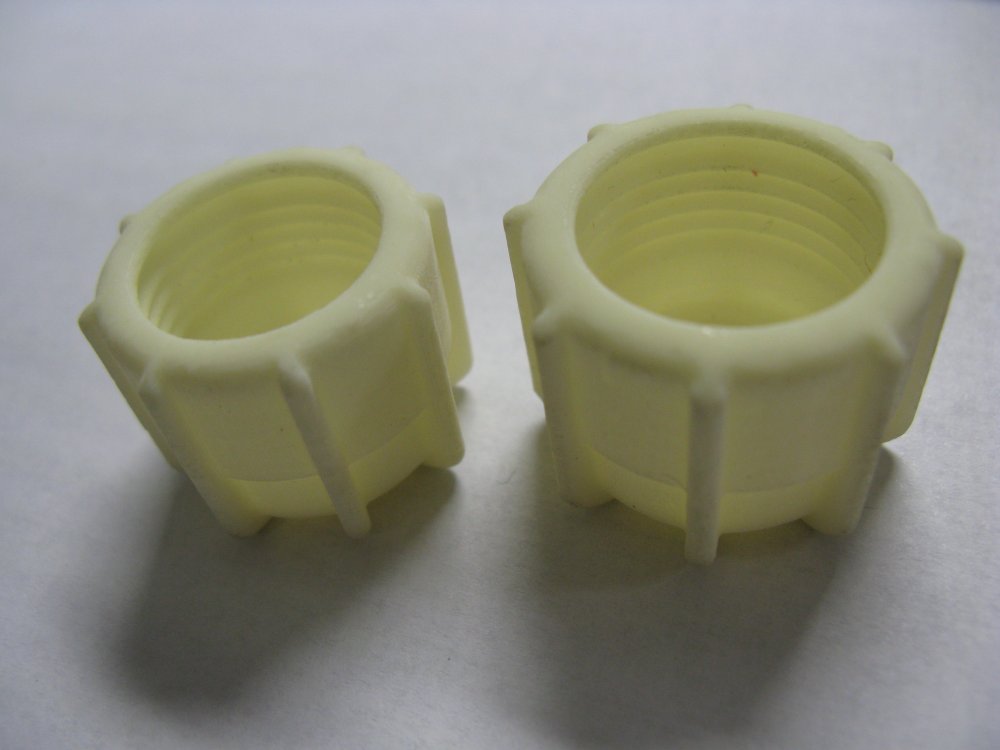

The machine that I'm looking at uses SLS. The material is very robust and seems to fit all of my requirements. Mechaniac, thanks so much for the info. Always nice to have input from someone experienced. I am almost done with my first printable model kit, so hopefully soon I will have parts to take pictures of. I will post them as soon as possible. thanks for all the great input!.

-

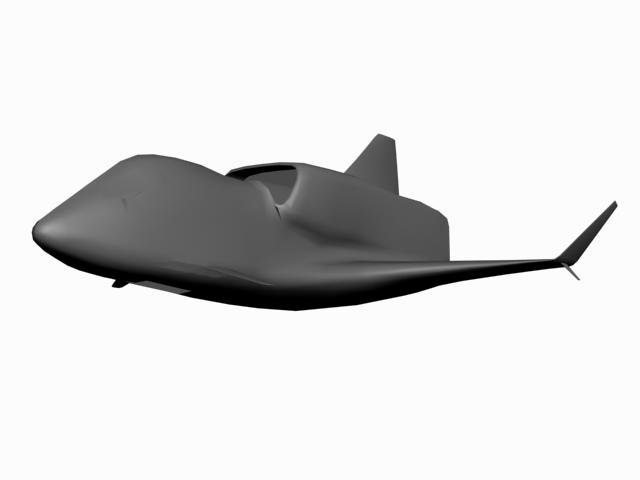

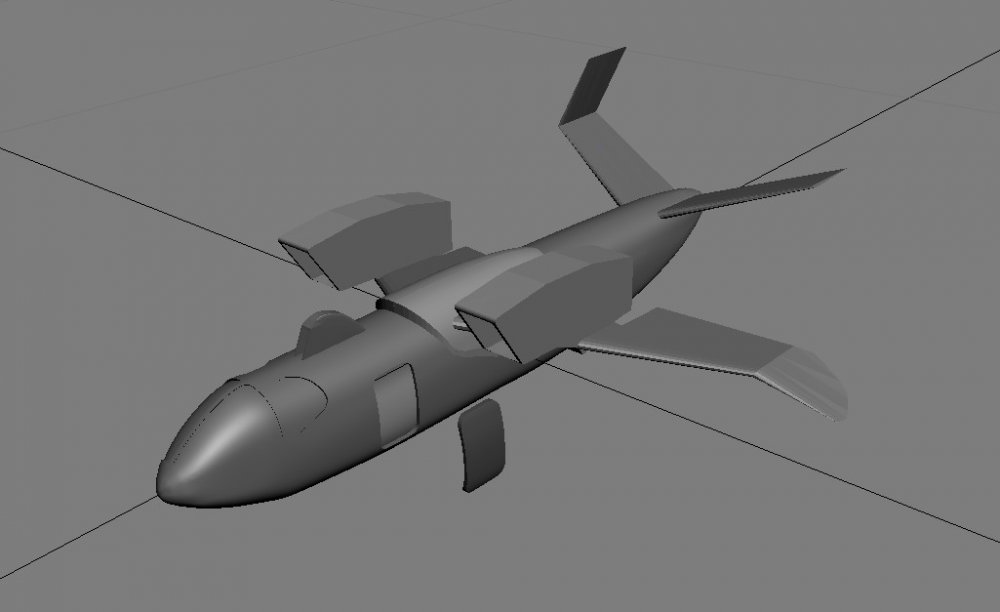

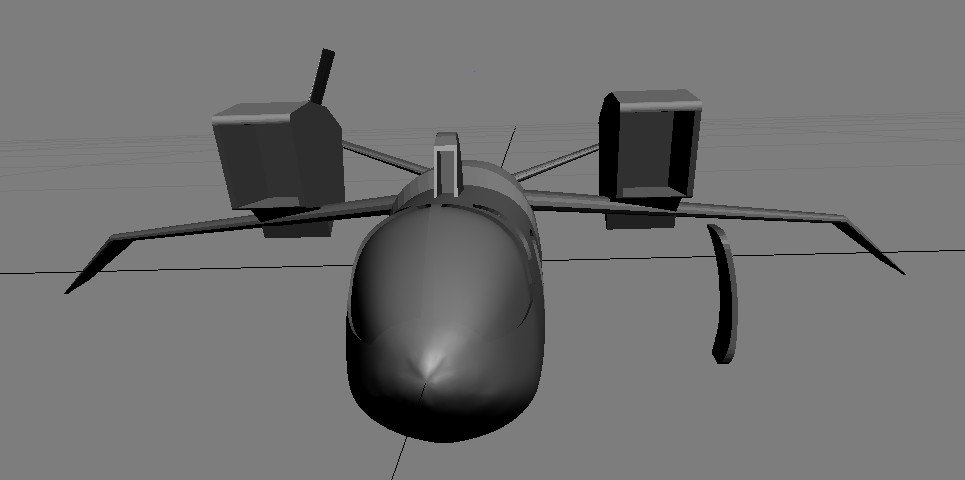

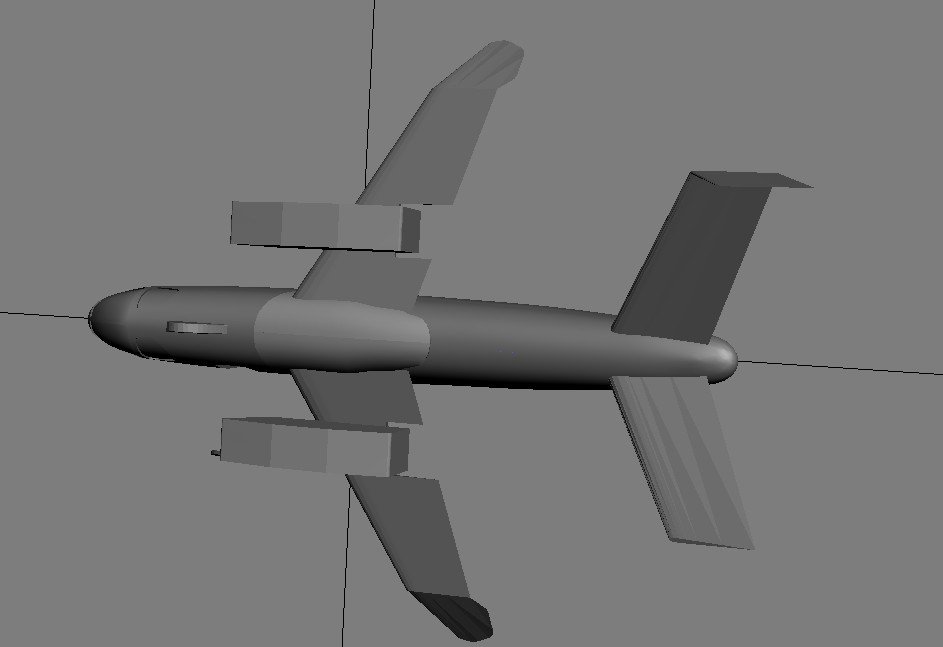

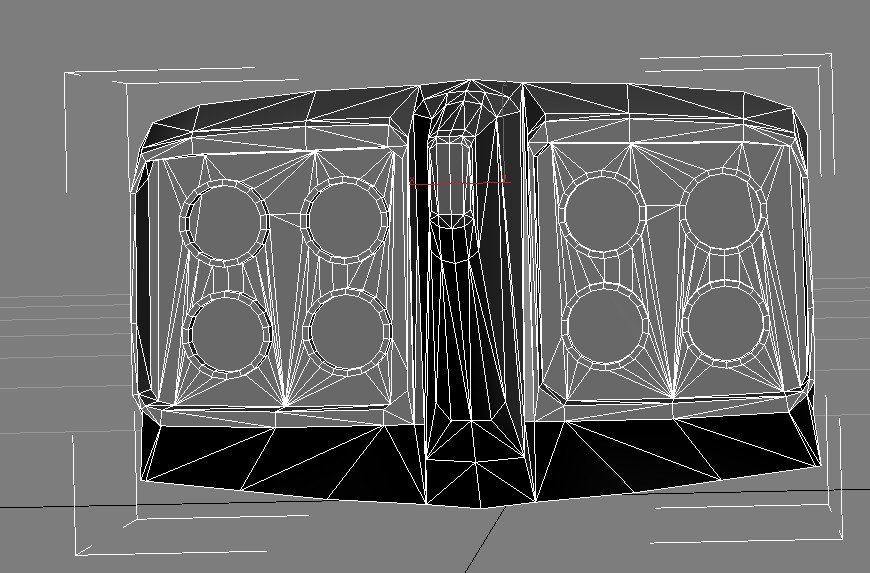

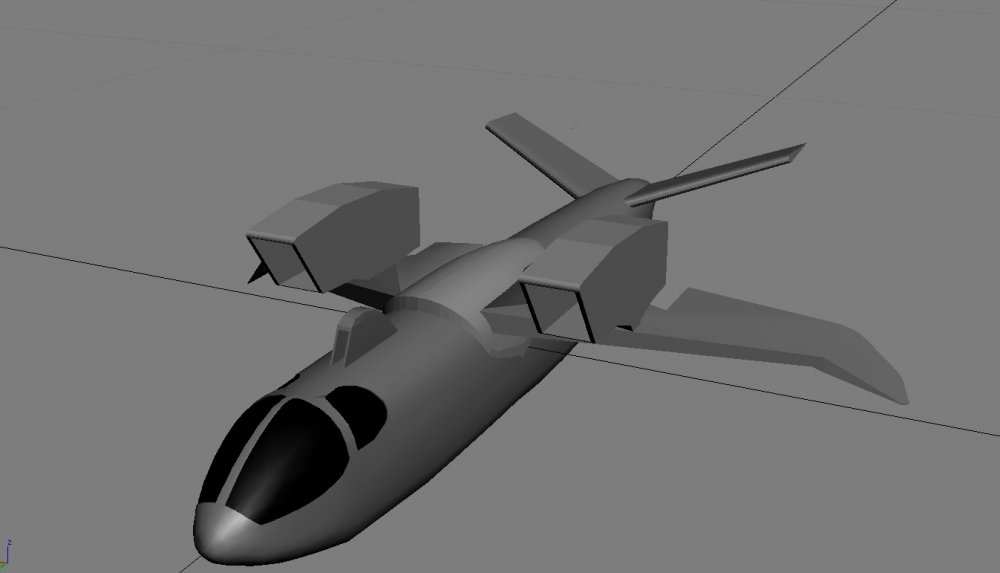

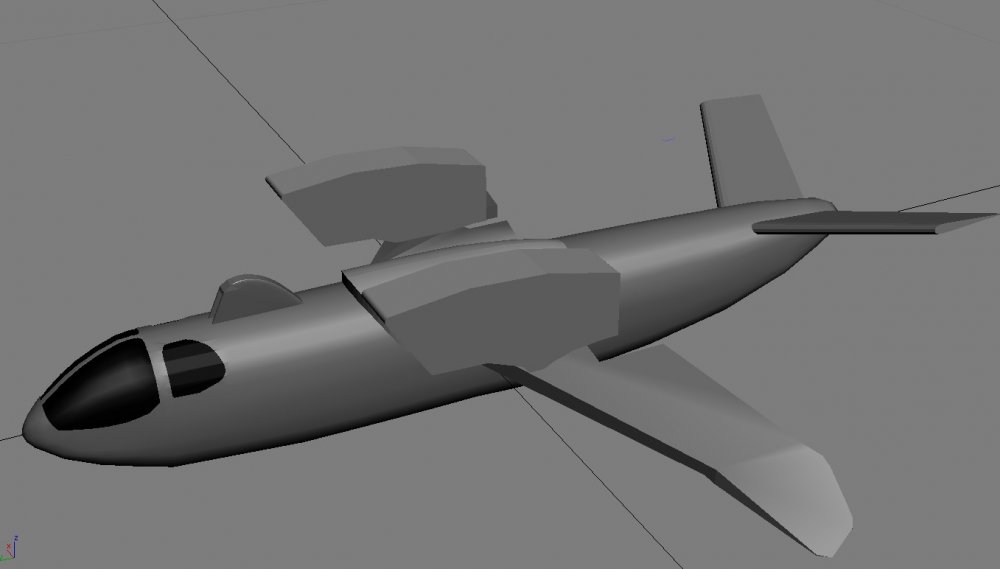

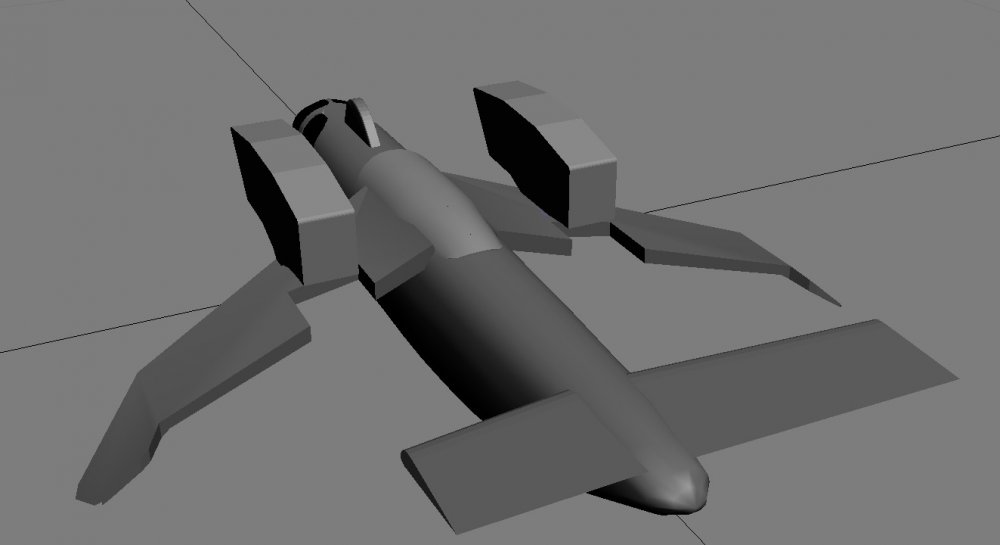

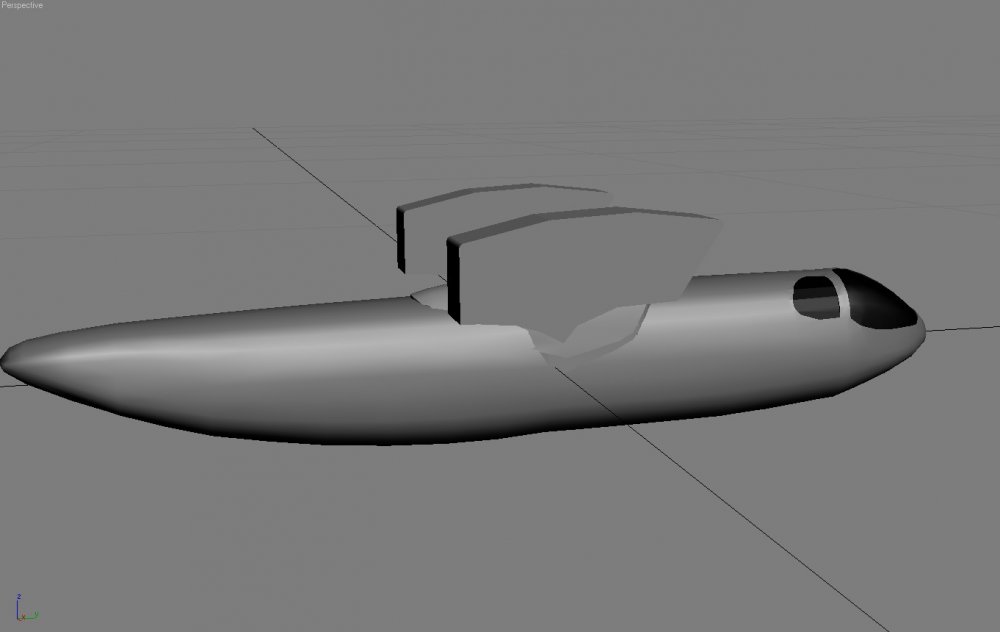

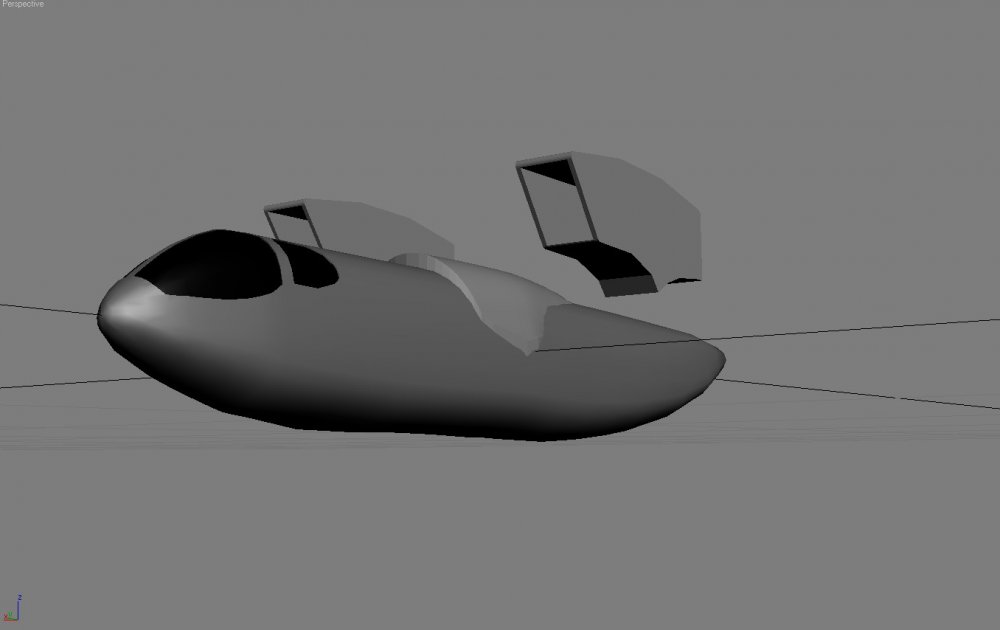

Another update, did some more detail work on the fuselage and wings, started to work on the tail a bit. Thanks for all the support. I will probably start to detail the engines and the landing gear next.

-

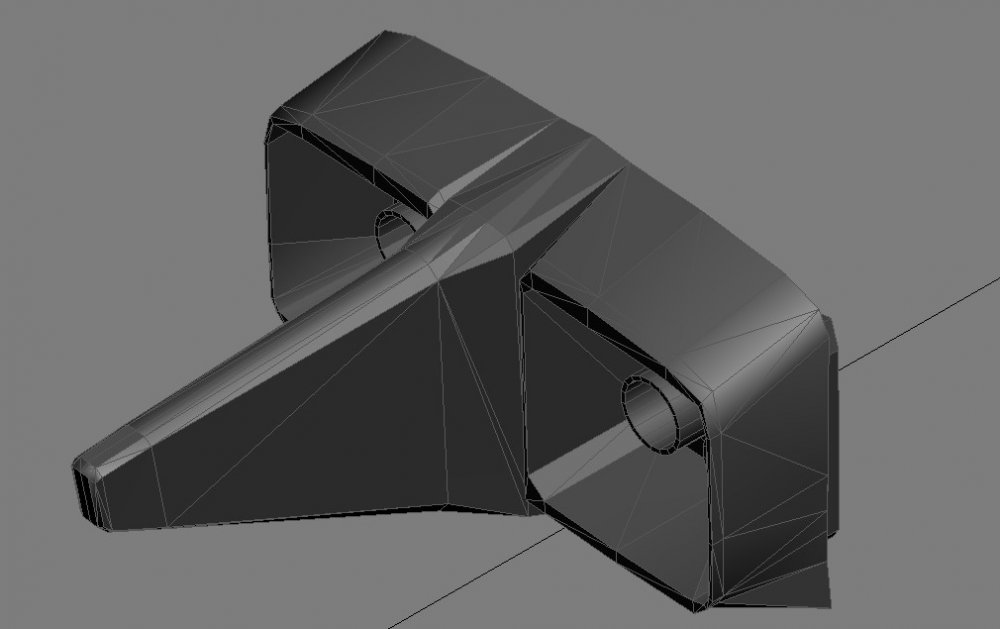

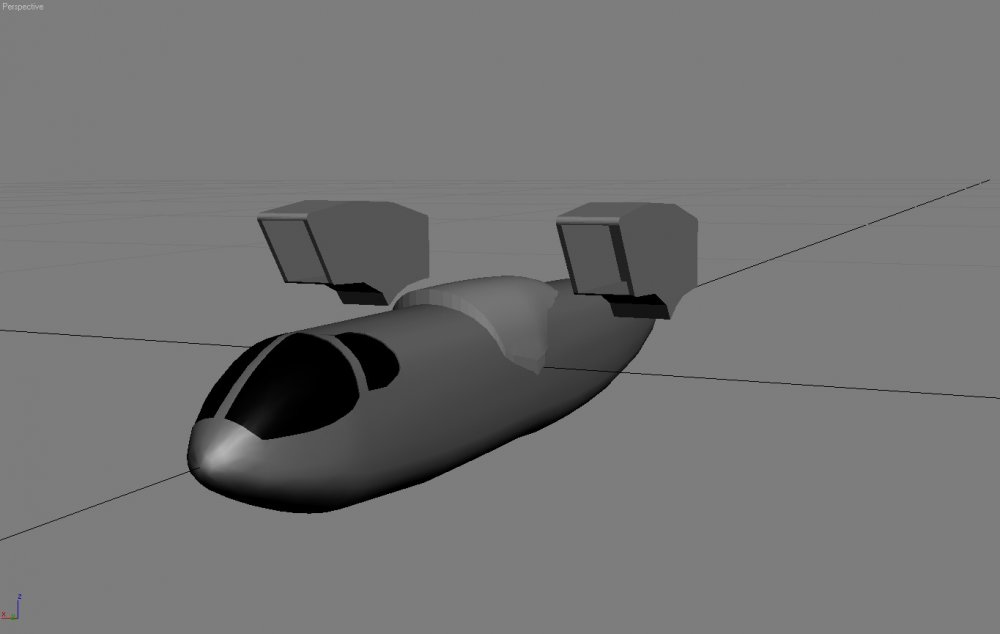

Just an update. I am finishing up on a sample part that I am going to have printed. Once I have the part in hand, I will post some pictures The part will be the back end of an SC-27 stargoose model that i am doing in 1/100 scale. Here is a pic of the model in 3d.

-

-

I have requested various samples from other manufacturers. They have not sent any even though they were requested. This company was the only one to send samples. I was able to go to a local school and see the dimension printer in action. the plastic seemed robust enough, but it printed in layers that were .010" thick and used small jets to apply the plastic. The unit that i am looking at, the V-flash utilizes a thin film of liquid plastic that is cured under UV lamps. This enables this unit to print faster and in more detail since the unit prints in layers that are .004" think. Not to mention that the V-flash is also about $4000 less than the dimension. There are other units out there that go for even less, but the resolution and layer thickness was the same or greater than the dimension. they also had an extremely small print area. The print tray on the V-flash is 9" x 6 3/4" x 8" (228 x 171 x 203 mm). That's not too shabby for the price. models that are larger than this can be broken up into sections and then printed. I have looked into units with larger print area's but they are in the $30000 plus price range. I think that the V-flash will give the most bang for the buck.

-

I was looking into getting a 3d scanner as part of this endeavor. There is someone on ebay who makes 3d scanners that are relatively inexpensive. If and when i get this project off the ground I'm sure something could be arranged.

-

Sorry for the delay, i had to go out of town, but here are photos of the drill test and the glue. I used a standard modelling glue and it is holding very well. The drill holes look pretty clean. Another idea I had would be to use the printer to make molds and that would further reduce costs. Some of my other ideas would be to maybe do 1/1 representations of equipment. I always liked the Gallant H90 from Mospeada so why not make one?

-

If anyone is getting these on Ebay, be careful who you buy from I bought a couple and never saw them. I got my money back but it was frustrating.

-

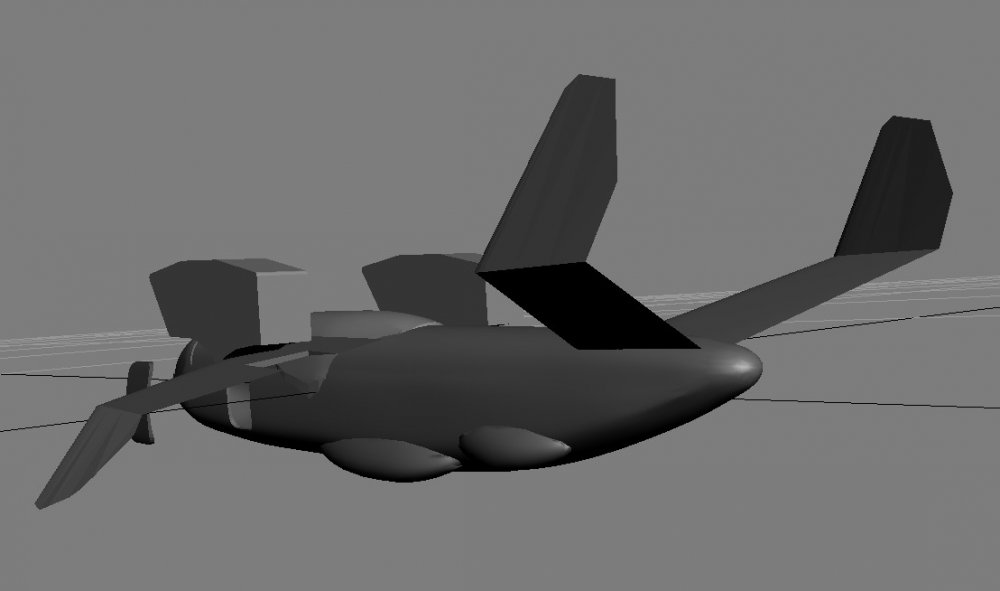

Hello all. I wasn't sure where to put this one since it is kinda related to my 3D printer thread. One of the first subjects i was thinking of "printing out" was a VC-33 mom's kitchen. Kinda been one of my favorites. Well here is the start of the mesh. any comments would be appreciated. please keep in mind that this is just a start.

-

Here are the pictures of the paint and sanding tests. the paint actually helps fill in the steps from the printing and smoothed the model out. So it appears that the plastic from a 3d printer can be painted and sanded quite easily. I will be doing the adhesive test and the drill test later today. i will post the photos by tomorrow.

-

I have received some samples. These are from the V-Flash. I took these pictures using a camera macro to bring out the detail. I must say that you can't see the steps with the naked eye (at least I can't) All that aside I'm pretty impressed with the results. Each or these steps is .004" thick. I will do a paint test and sanding test to see if this will smooth out some of those steps but the detail is pretty good. these samples were created from the same model, in different scales. Which is pretty much what I want to do. I have been working on a couple models to test. One of the is a VC-33 Mom's kitchen and The SC-27 Stargoose. Someone sent me a rough 3d model of the Stargoose that I am modifying so it is more accurate and detailed. I will post pictures. The Vendor I am dealing with will let me print a test model at cost and I will then post pictures here and get some more opinions.

-

Good point. They make the decal paper in clear and white. you could use the white background to your advantage, the drawback is cutting out the decal would be tricky.

-

Have you looked into printing your own? Check this out. http://www.decalpaper.com/product-p/10c.htm You can just print out your own. There are a lot of products like this, just look around. I think this is the least expensive decal paper I have found.

-

Thanks for the info. actually they are using one of the printers I am considering. I might just get a small model printed to see what it can do.

-

The models I was looking at are between $9000-$14000. I'm still doing some research, but the 2 machines I'm looking at are the Uprint from Stratasys, and the V-flash from 3d Systems. The reviews from both seem pretty good as far as maintainence, and I actually know a couple schools locally that have the Uprint so I'm gonna get to see that one up close. I would like to hear more about the machines that you are working with though. From a professional standpoint i would love to hear your thoughts on the process as an alternative means to traditional tooling and prototyping methods

-

Thanks for all your input. There is no doubt that technology is moving forward at a very fast pace. eventualluy you could go to Walmart and buy a 3d printer for 99 bucks. from a lot of the technology shows and such that i watch everyone seems to think that in the future, you would just download the scematic for whatever car, or device you are buying and then print it out on your home 3d printer. Heck they are even talking about printing Human tissue. Before this gets into a technology debate, I just want to make clear that my motives for getting this machine come from 2 places: 1) for my own use for my job. It would be nice to be able to test my designs quickly. without having to tool them. 2) The reason I posted this thread. As I look around this site at all the cool ideas and the scratchbuild that people are doing one of the most common things I keep seeing is "could you make this in (whatever) scale", or "I would love to get my hands on one of those." well i hope my point is made. I agree with Capt. that this should in no way replace scratchbuiling as an artform. I simply saw a way to possibly fufill some of those requests that i see made so often on this site. Most likely I will purchase this machine for my job. If I do so i will maybe do a couple test prints of some basic models and post them just to see the limitations of this device. I'm not in any rush to get this machine right away. I want to make sure it will meet my needs for my job first. I appreciate all of your suggestion and comments.

-

Okay I have found another possible machine check this out and tell me what you guys think. this one prints with a .004" thickness. http://www.modelin3d.com/specs

-

okay i found a few sites that have some detailed pics. Think I will still have them send me a sample part though. http://www.huv.com/blog/2009/09/3d-printer.html http://www.iheartrobotics.com/2009/07/cool...ter-update.html