-

Posts

3561 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by captain america

-

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

The paper templates are mostly shape outlines. When I have to deal with more complex forms, the paper templates can only convey so much info, so once I start Dremeling I have to switch over to intuitive mode. Also, there's a lot of stuff I just eyeball, like the knee joint. I had one thing planned in the drafting stage, but once I started cutting, I saw that I could get more range of motion if I ventured beyond the blueprints, which is what I did. That's both the challenge and fun of taking sketches that someone phoned-in and turning them into something usable. I take Paypal & Bitcoin, just PM me for details. -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

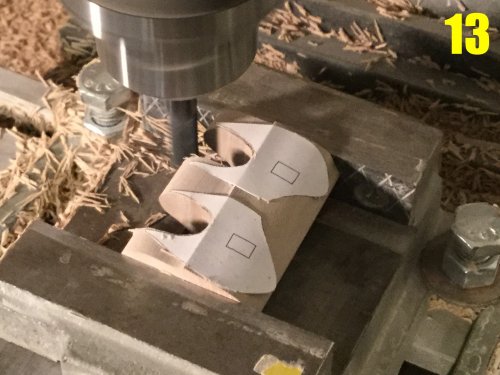

Captain’s log: February 10th, 2021 Pic 12: the adventure continues as I can now begin performing secial operations on designated parts. Here you can see the calf module being hollowed-out for the joint interface. Pic 13: a similar operation being performed on the thighs. Because of the shape of the parts, the paper templates will be slightly distorted by conforming to the block, I’ll have to make some minor pencil marks to adjust the shapes prior to further cutting. Pic 14: now that I have some basic parts taking shape, I’ll need to make some ball-joints. My lathe was perfectly clean just 5 minutes before this pic was taken. Initial operations are done with knives, just like working with metal. Pic 15: unlike with metal, turning resin does offer some advantages, the first being speed of machining. The other is that I can employ hand tools and sanding blocks to sape parts. Here you see me using a photo-etch saw on a part to scribe lines. Pic 16: some crude shapes now beginning to resemble the intended subject. These will be put aside temporarily while I labor on the joints. Pic 17: things get dirty fast when I whip out the rotary tool, but it’s so much fun! The calves are the first to get the shaping treatment. I actually have to stage these shots, because it wouldn’t be safe for me to be grinding the part while holding the camera in my lap… To say nothing of getting dust all over delicate electronic equipment! Pic 18: one of the more challenging parts to make are the thighs. Their overall jellybean shapes need to be perfectly symmetrical, so I operate on both of them in slow sequence, making sure to check my dimensions frequently. It’s a lot of tedious back & forth, and it needs to be done right. Pic 19: to a normie, this would look like a mess, but it’s carefully harnessed chaos. Mold release is applied to one part, while ample putty is applied to the other, then they are both pressed together to achieve perfectly fitting, conformal parts. It’s more an art than a science, because you have a very short window in which to pull the two components apart to get the desired effect: too soon and the putty will crumble and the effect is ruined, too late and the parts will be bonded together! Pic 20: more putty shaping taking place here, this time with Tamiya polyester (yellow) putty. This actually gives a cleaner result than the Bondo (blue) putty, but takes 10 times longer to harden, so there are different putties to be used for various operations. Pic 21: here we see the arm, wich is 60% done. If you study the original line-art, you will see that the elbows are drawn such that they are both facing outward on each side, and the arm bends in the direction shown by the red arrow; basically like an ape. So how do I take this clusterfrack retarded elbow joint and make it bend sensibly while still remaining faithful to the source material? By cleverly repositioning the joint! Pic22: you can see here that the bending point is camouflaged, but through a combination of joints I can get a 90 degree bend. Considering the limitations of the source material, I’d call that a win, and there will be more. Pic 23: I’m not quite sure how, but BIO LLOYD is looking really good, really early into development—an encouraging sign to be sure! As of today, you can begin sending in payment for your kit(s). The details for CAN/US customers is in the pics, while overseas customers can make arrangements with Return2KitForm -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

It's fun to make, too! I've found quite a few interesting hacks to make the design more posable while still being faithful to the source material. i can't wait to show you more. -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

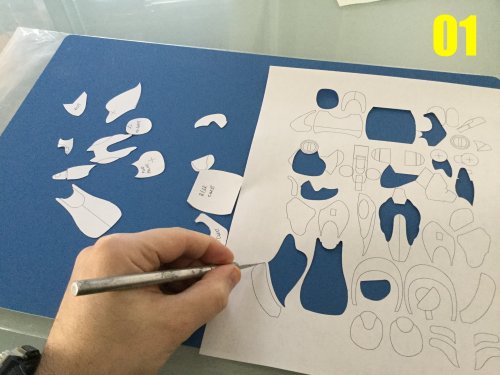

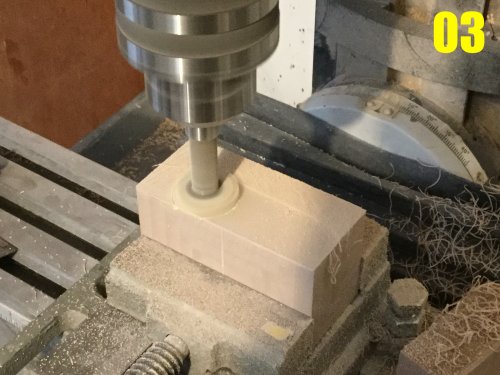

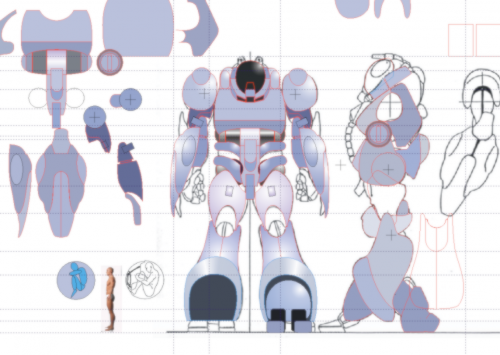

Captain’s log: February 3rd, 2021 It begins! After about a week of studying, tracing, correcting and editing rudimentary technical diagrams, I’m finally ready to start chopping modeling board. The START image shows you all the basics I start my project with: -several print-outs with parts diagrams and line-art references -modelling board blocks of various sizes; some of which were scavenged from other projects -some 2-part expoxy sculpting clay (this will come in handy later) -some thin CA glue Pic 01: the plots are now carefully trimmed-out. Because there are so many generic looking blobby shapes, I’ve made it a point to scribble notes on some of the templates to better keep track of them. Pic 02: because work on the milling machine is critical to the construction of any project, I figured I’d show you some of the cutters I use most. From left to right: a bull-nosed (detail) cutting flute, a 4-blade standard cutter, and finaly a face-end mill. The latter is used for creating perfectly flat surfaces. As a rule of thumb, the fewer cutting blades on the shank, the faster you can carve the material. Pic 03: some initial surfacing going on before I attach the paper templates. I can use this tool for blocks, but when I need to re-surface smaller parts, I will generally resort to the drill press. I use this face-end mill whenever I can, just because it produces less dust. Pic 04: some of the blocks need to be cut down to size, just to avoid wasting excessive material, so the larger pieces are chopped-down on the band saw. Because the saw makes a jagged cut, the block will need to go back to the mill for proper surfacing. Pic 05: only after a considerable amount of block re-sizing can I begin to attach templates to the blocks. Many times I will have both a plan and side template, but cannot attach both at the same time, so I need to add one template, shape the part to that one view, then I can attach the second one. Pic 06: the grinding stone on the drill press being put to good use shaping one of the many curved parts. Pic 07: I’ll use the band saw to do some rough trimming of many parts. Because I can’t do precise cuts with this tool, I always have to leave some extra material and remove it by other, more precise means. Pic 08: one of those more precise means is the mill. Depending on the part, this can be a very tedious process, using many square-cut passes to make a pseud-rounded shape, but it’s precise AF. Pic 09: once the bigger machines clear away most of the excess, I can now get in close with a sanding block and get the shape just right. Pic 10: I loathe parts like this. This long, curved part is actually the cross-section of the ankle armor, which I need to make as left and right pieces. By making the cross-section as one piece, I can more easily ensure that the parts will be mirror images of each other. The concave curvature must be machined one pass at a time. Pic 11: this block represents the cross-section of the thighs, which underwent the same process which you saw in pic 10, and can now be sanded to conform precisely to the template. You can se that there’s still some excess material that the mill didn’t remove, and that’s a judgement call: the mill is precise but slow, and there’s a point beyond which extra milling will not yield extra precision and manual shaping can be done. It all depends on the shape and the part in question. While this probably wasn’t the most exciting update with regards to progress, it’s probably the most critical and informative in terms of laying-out the process by which an idea is turned into an almost-part. More to come next week, so stay tuned! -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

This. The BIO LLOYD project was only possible because a devout fan decided to bankroll the tooling of the masters. Due to the complexity of the project and the generally lackluster support for SC, I don't think it would have been possible to purely crowdfund it. Because of their devotion and because I don't think anyone else will ever give this design the treatment it deserves, I'm giving this project the 110% treatment. Expect an update by Thursday at the outset. -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

Hi everyone! I'm pushing the first BIO LLOYD pictorial update to next week. Progress is actually going very well, stay tuned! -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

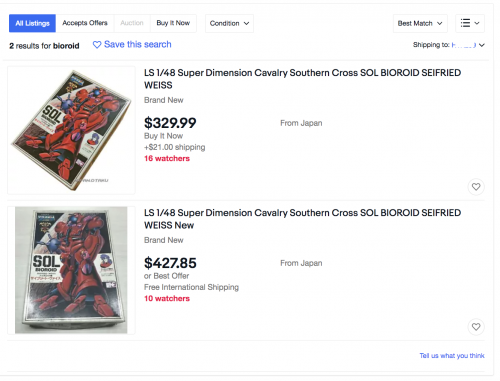

In fairness to L&S (not Arii) they could only do as well as technology, budget, and source material allowed them to. Remember that they weren't fans: they answered to accountants and a corporate structure that saw this as just one more franchise to milk for profit and move on. Speaking of that particular kit, have you seen what the originals are going for these days? -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

Even split into two parts, each half is considerable in size, so the mold box will have to be custom-made regardless. I'm also seriously considering making some parts from flexible resin to offer posability without violating the source material. -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

BIO LLOYD will be a little over 17cm tall in 1/48. I always begin with the human pilot and cockpit as a starting point to determine the mecha size. They had created the art for the cockpit ball cutaway, so all I had to do was size it such to fit into the mecha's neck/upper chest area. Of course, the mecha's size contradicts the numerical dimensions, but that's nothing new. The hover-sled will be bigger than the mecha itself: 24 by 18cm. That'll require a massive custom mold box. I only use the animation as reference if nothing else is available because it's so inconsistent. Besides, the line-art is the primary reference that the animators use, so I make that a priority. -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

Contact Brett over at R2KF, he'll take care of you and as a fellow Aussie, your shipping will be substantially cheaper. -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

Hey everyone! Just wanted to let you know that BIO LLOYD drafting is progressing well. Or rather, as well as it possibly can, given the nature of the source material. However abstract and disjointed the line-art from previous projects was, this one is its own, special kind of clusterscrew! It's not bad enough that the line-art just looks like a bunch of jellybeans cobbled together, and the multiple views contradict each other, I'm used to that. But the joints on this thing were really just phoned-in, even by Anime standards! As such, I'm performing high-level creative gymnastics to give this thing a reasonable degree of articulation while still keeping true to the source material. As I progress into the sculpting, you will start to understand why this will be a bargain, even at 300 bucks +. A glimpse into my technical drawing madness: -

1/48 SOUTHERN CROSS BIOROID

captain america replied to captain america's topic in Anime or Science Fiction

You'll be able to build any of the three variants (Cherry, Green Apple, Blueberry) from one kit. -

Hey everyone! I just wanted to share this project with you, because there seems to have been at least some interest in Southern Cross mecha. A fellow MWer has commissionned me to make the master patterns for a 1/48 SPACE BIO LLOYD (Bioroid) complete with its FLYING CONVEYANCE (hover-sled) and I wanted to know how many people would be interested in a kit? Consider this to be that rare opportunity to get a properly sculpted model of this subject from this otherwise obscure series. The kit will have the following features: -built in accordance to original, primary visual source material -integrated (free-pose) ball-joint system -parts to build one of the three primary variants -includes FLYING CONVEYANCE Kit price until March 1st: $300 CAD + shipping Kit price after March 1st: $330 CAD + shipping Shipping charges will be determined at a later time. Take some time to think it through, see if finances permit. If you think you can manage it, then by all means, let your typing fingers do their thing.

-

The Mandalorian - Star Wars webseries from Jon Favreau

captain america replied to SMS007's topic in Anime or Science Fiction

- 1438 replies

-

- 2

-

-

- star wars

- the mandalorian

- (and 10 more)

-

The Official Moscato Hobby Models Thread

captain america replied to captain america's topic in Anime or Science Fiction

My first attempt at video! https://odysee.com/@moscatohobbymodels:7/M72-Gabriel-In-Box-Overview:b -

New 1/350 MOSPEADA Garfish Project?

captain america replied to captain america's topic in Anime or Science Fiction

-

New 1/350 MOSPEADA Garfish Project?

captain america replied to captain america's topic in Anime or Science Fiction

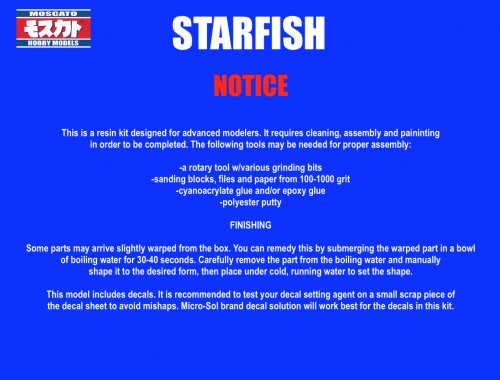

Quick update! All paid orders have shipped. Some people have asked if more kits will be available, and my answer is: it depends. The molds on this kit are rather substantial, so I would need a minimum of 10 orders to justify the retooling. If you're one of those interested parties, let me know via PM. -

New 1/350 MOSPEADA Garfish Project?

captain america replied to captain america's topic in Anime or Science Fiction

-

22 karat gold leaf or bust! Not the imitation stuff, it's trash.

-

I have the resin kit, and just as with the LED Mirage, there are some elements that are slightly better on the IMS kit. Of course the resin offering, being first and hand-made, is a pure work-of-art. The Mighty series kits are well done, but I never cared for the designs all that much. I also seem to remember them being a bit on the short side, but maybe that's just me. Volks also seemingly has an Auge in the IMS pipeline. Maybe next year. Meanwhile... This might just be the cranky old perfectionist in me, but every time I see someone finishing the KoG without using proper gold, I'm irked.

-

Video footage of the built model of the IMS Knight of Gold.

-

Yes it should be. Pretty good compatibility, all things considered.

- 14207 replies

-

New 1/350 MOSPEADA Garfish Project?

captain america replied to captain america's topic in Anime or Science Fiction

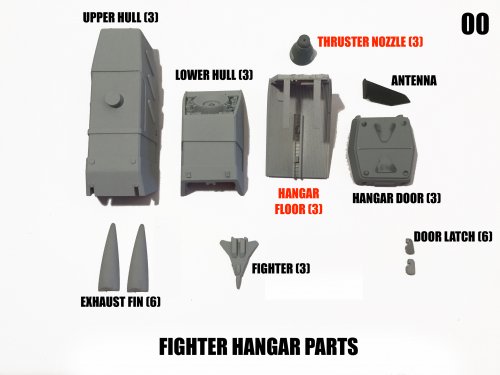

Thanks, it was quite a challenging project to mold. Despite that little difference in size, I really had to change-up my mold boxes and the whole thing needed over 10 lbs of silicone. I'm quite pleased with how it turned out. -

You're right. At a glance it looks almost the same, but there are some subtle differences in proportions and details. I still think the WSC version is the more elegant of the two. We'll have to wait and see how big this one is, but the price is fair, considering where plastic and resin kit prices have gone in the last 25 years.

-

New 1/350 MOSPEADA Garfish Project?

captain america replied to captain america's topic in Anime or Science Fiction

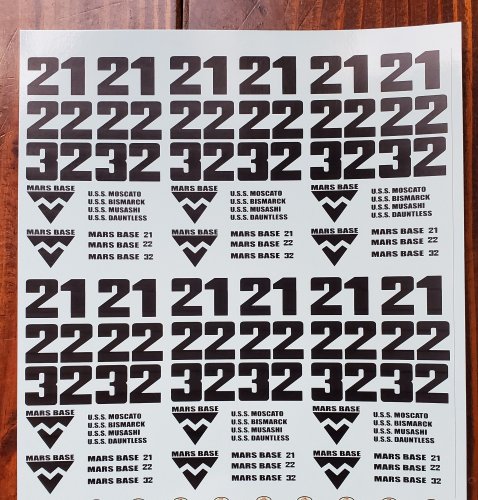

Captain’s log: Friday, October 30th. Sweet victory!! Molds are done, decals are done, production has begun, and parts look excellent. You can now send in the balance of your 1/350 Starfish payments. for those who have paid the $150 CAD deposit, your balance payment is $187 CAD. I won’t be taking any new orders for this kit the time being: the order block is completely full and I want to concentrate on existing orders.