-

Posts

3550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by captain america

-

-

-

This pic makes the part look fairly rough, but in reality, there are only a couple small bubbles to fill at the top.

-

Hi all. Yet more pictures to share, this time of the actual cast resin parts. These are actually the test-shots made in a low-shrink resin; the final castings made by Jesse will be of a more conventional resin, which is notably easier to sand and grind. As you can see, there are still the obvious mold lines to contend with, as well as a bit of flash, but the detail is excellent overall. All the scribing and rivets reproduces perfectly. I also tested the castings for fit, and everything fits as it should.

-

John Moscato's Legioss project.

captain america replied to Less than Super Ostrich's topic in Model kits

Unfortunately, I can't share any photos or diagrams of my firearms projects, as they are still development prototypes and haven't been patented yet. Legioss: aside from the obvious casting hurdle(metal parts, not just resin), I'm simply not anxious for another potentially messy showdown with Harmony Gold's legal arm. I tend to like the position I'm in now with the booster project, where I'm simply a subcontractor for a firm operating outside of HG's jurisdiction. Simpler for me. -

John Moscato's Legioss project.

captain america replied to Less than Super Ostrich's topic in Model kits

As of this week, I'm tasking myself with the finished Macross Valkyrie booster, as well as plotting some initial drafts of the launch vehicle. In between those two, I have to work on a second-generation design of my firearms project... My life is like a never-ending arts & crafts session -

John Moscato's Legioss project.

captain america replied to Less than Super Ostrich's topic in Model kits

All of the sculpting was finished a while back, but the only way to truly "finish" it was to mold everything and cast it. I just don't have time for that in the forseeable future. -

John Moscato's Legioss project.

captain america replied to Less than Super Ostrich's topic in Model kits

http://www.macrossworld.com/macross/_main_menu.htm The upper right-hand corner box clearly says "project canceled"... And yet people still ask me when it's going to be available -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

Hi Radd. The biggest problem with all that is reallya lack of space. I had actually wanted to try something with reflective mylar acting as a mirror to project the light more effectively, but the inside of the bridge is just so small, and the lighting "hole" must be so very small as well, that as soon as your light source is more than a mm away from the projection hole, the light beam becomes so narrow as to become useless. David: if I understand you correctly, then I need an adapter in the range of 4.5 volts, which would be an identical replacement for the three 1.5 volt batteries that the kit uses as standard. Having said that, might you have a clue as to what my safe threshold of voltage is for 15 LEDs? Also, since an adapter, as you said, regulates voltage, then I wouldn't really need a resistor...Or would I? My biggest failing at this point is that I don't know the difference between volts, watts and amperage, but I do know that the milliamp rating on a battery determines the "duration" of power that it'll provide, and that if a device consumes 1200 ma/hr, and your battery provides 1200 ma/hr, then you'll only have an hour of battery life, and so on. I may yet eventually get the hang of this -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

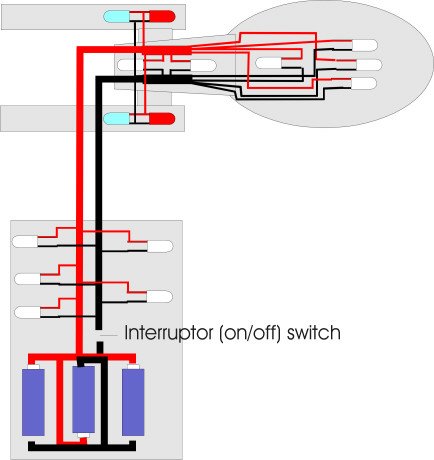

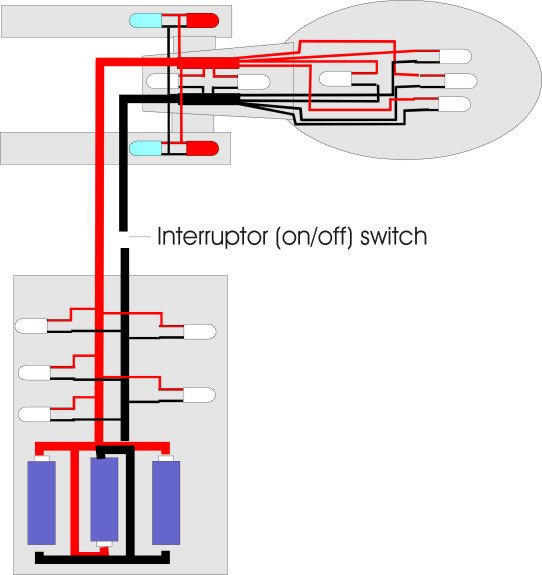

Hi Stamen. Yes, you're right, my diagram above was flawed. This one is accurate to the actual model, with the power switch clearly between all the LEDs and the power source. I'll re-read the above comments again... Hopefully to understand them this time. I really appreciate all the help offered thus far -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

Hi Stamen. I can get access to the wires that are coming out of the ship, as well as the contacts to the power supply (batteries), but not the wires inside the vessel itself. In essence, based on my diagram above, everything "below the ship" is hands-on, but everything inside is not accessible. Am I screwed? -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

-

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

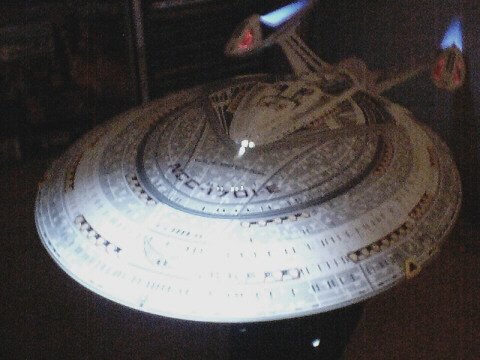

Top of the saucer. The light projection onto the hull is courtesy of an LED which I held dangling over the model as I snapped the pic. Though there's a light shining from out of the base of the bridge decks, it barely projects onto the hull at all; the LED being too large to aim downward from inside the crowded confines of the kit's interior. -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

..And a few more awful pics of the finished model, which I can proudly say I assembled with NO painting whatsoever. I swear, these Bandai shake-n-bake models are like scaled-up versions of those little Kinder Egg toys... Makes me think it might not be such a bad idea to market them encased in a chocolate egg -

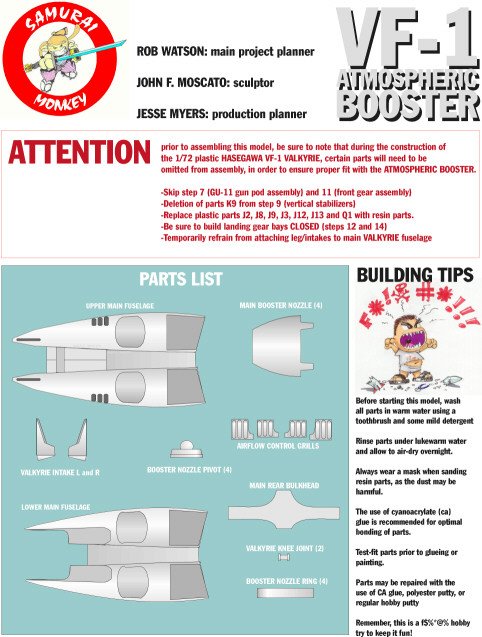

The Samurai Monkey character art in the company logo was provided by Rob; I simply dressed it up. The irate little guy at lower right is a marker rendering by me of myself at work.

-

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

Aight... Read the article on LEDs for dummies. Flawed article, because I'm more confused now than before I read it... Us simple-minded folk prefer diagrams; makes learning easier, so I included one of the wiring on my model. The only thing that's wrong in the diagram is the position of the on/off switch; it should clearly be between ALL the LEDs and the battery contacts. Hopefully, this will provide a clearer indication of what I've done, and if it can be converted to a wall-outlet. -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

Hi stamen. Sorry, I'm just VERY new and dense with all this. Would I need a resisor for EACH LED in the kit, and if so, do I need to place it right on the LED itself? The ship itself has been glued shut, so I can't get inside it to access those LEDs anymore, but the base/battery box is still accessible. Inside this display base, there's essentially two main "poles": one positive, one negative, and these connect to the battery contacts. I simply soldered all the red wires from the LEDs to the positive pole, and all the blue ones to the negative. I was just hoping that there would be a way to replace the battery box (and batteries) with a wall outlet, and maybe a resistor of some sort in between them to keep from blowing the LEDs. Alas, I'm an artist, not an electrician, so even the simplest of wiring jobs is a big step for me... Makes for a purdy model though -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

Hi Stamen. The LEDs in question are superbrights, I guess. 5mm, 10mA there are 6 "white", and 2 blue superbrights inside the ship, and two regular red LEDs (non-superbright) in the front of the nacelles to light the bussard collectors. The 5 in the base are white superbrights also, all are 5mm size. If it helps, the radio shack parts number for the white superbrights is 276-9083...2 per pack. -

Question about lighting models.

captain america replied to captain america's topic in Anime or Science Fiction

Hi Valkyrie. Well, I took the plunge and replaced all the lamps in my Enterprise with superbright LEDs. In fact, I went even further, by adding 2 extra LEDs inside the saucer section to produce the "projection" effect onto the hull. The one on the top didn't come out as great as I would have liked, as it's hard to get a proper light patch onto a surface that's dipping away from the light source. I also added 5 LEDs into the black base which serve as spotlights to illuminate the lower hull... Not bad for a guy who sucks at wiring things! Ok, now here's the thing. This kit now has 15 LEDs, which are powered by 3 AA batteries, and I'm guessing that since there are so many bulbs, that the batteries just can't produce the brightness that I seemed to get when testing the bulbs one at a time. Essentially, would there be a way to make the whole unit capable of using a wall outlet for power? Perhaps using some sort of off-the-shelf plug-in adapter unit? I'd ask the guys at my local radio shack, but judging from the blank expression on their faces when I asked them about LEDs, I figured it would be safer to ask here -

-

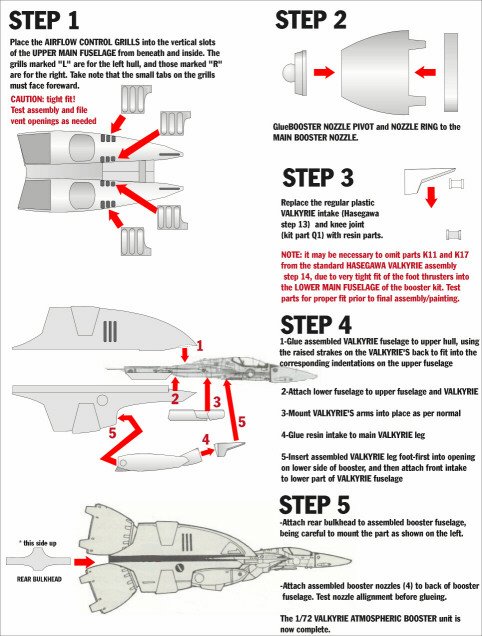

Hi all. It's been a while since my last update, so this is a bit overdue. The molds for the Boosater have all been completed, and aside from a few leaks which have since been repaired, all the test-shots look excellent... The quality will be comparable with what you get on a CLUB M/Work Shop CAST kit, save for a tad more flash. The masters and molds are currently en-route to Jesse, and if all goes well, he should be pumping out the first few kits next week. Just as a quick teaser, here are the shots of the instructions for the kit... I'll try to post some pics of the actual castings later this week. Cheers...

-

Hi all. I have a bit of a technical question for those of you who may have some experience in lighting model kits. I'm currently looking at a newly-purchased Bandai NCC-1701E Enterprise kit, and I had some questions about the small grain-of-wheat bulbs included. Essentially, these look ( to me anyway) like scaled-down versions of regular lightbulbs, and as such, that most probably means that they'll burn out eventually. Problem is, once the model is properly built, there would be no way to open it back up to replace them. So in short, my question is twofold: what is the expected life of these grain of wheat/rice bulbs, and do they have any advantages at all over LEDs (particularly superbrights)? Thanks in advance for anyone who could, um... Shed some "light" on my dimness

-

NEW Official MPC Thread!!!

captain america replied to FRED THE FRENCH's topic in Anime or Science Fiction

The more I read about it, the more it sounds like this thing is a real piece of garbage... Or crap. The term "MPC" suits it well. Bravo Toynami, I applaud you. -

Hi guys. Just wanted to give you a quick update on what's going on. I've already begun pouring the molds for the masters, and hopefully that process will be done by friday evening, or Sat morning at the latest (cure time and all), with the first test-shots ready that same evening. My goal is to get a set of molding masters off to Jesse first thing Monday, so that he can begin making molds & casting. My guess is that whole process will take him at least a week to get started, so I'll be making the first kits over here, just so that we don't have to keep folks waiting too long for their models. Hopefully, I can start shipping the first kits within 10 days from now. Cheers,

-

Hi WM. Actually no, because of the way that the booster litterally "wraps around" the fighter, it can't simply slide in & out. Since there was no official reference material for the booster ejection, I made it so that the very tips of the lower fuselage are designed to blow away with exploding bolts, and pressurized C02 nozzles would then "push" the Valk down slightly, and then the Valk's own thrusters would allow it to slide free of the booster structure. I didn't make those tips separate on the kit, simply because my parts tally is already up to 15, and I wanted to keep the kit as simple as possible.