-

Posts

175 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by ImChris5115

-

-

@no3Ljm @rematron @Test_Pilot_2 @twich @M'Kyuun Thanks guys, appreciated!

-

Hi @no3Ljm, That's a cool video you shared there. I'm sorry, man. I wish I had experience using 3D Max, Maya, or Blender to do 3D animation. I know how to create 3D designs using CAD software like NX, Solidworks, and AutoCAD. But I'm only able to create exploded views and parts animation. I totally have no skillset in VFX and animation shown in this video. I admire those talents who are able to create something like that.

-

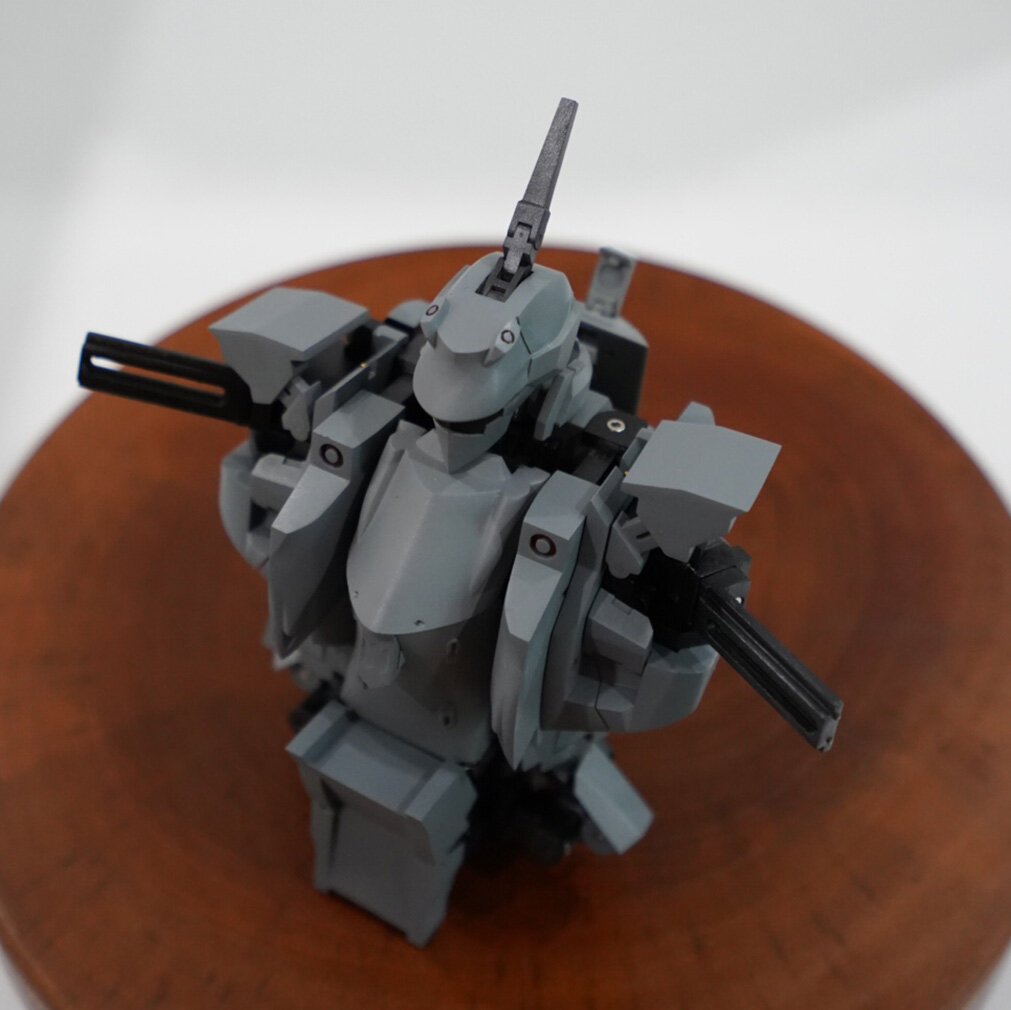

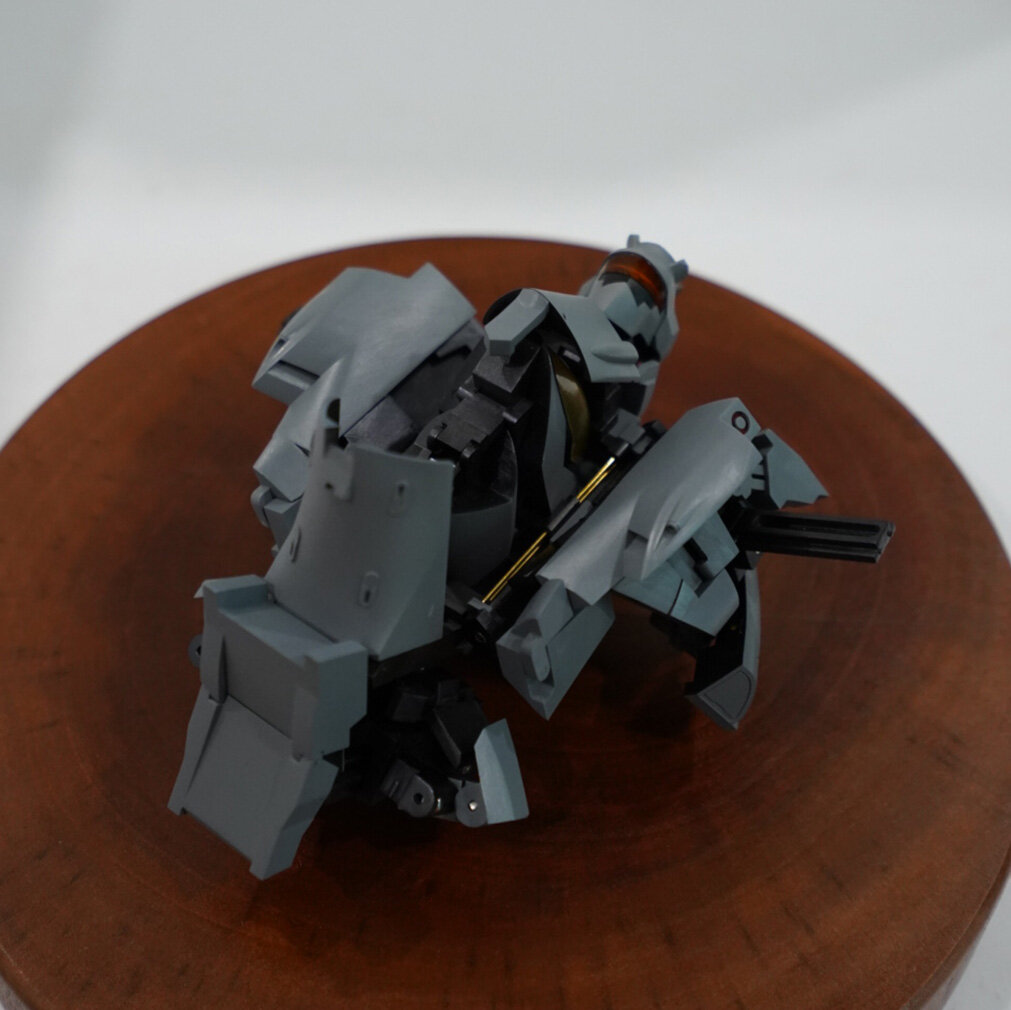

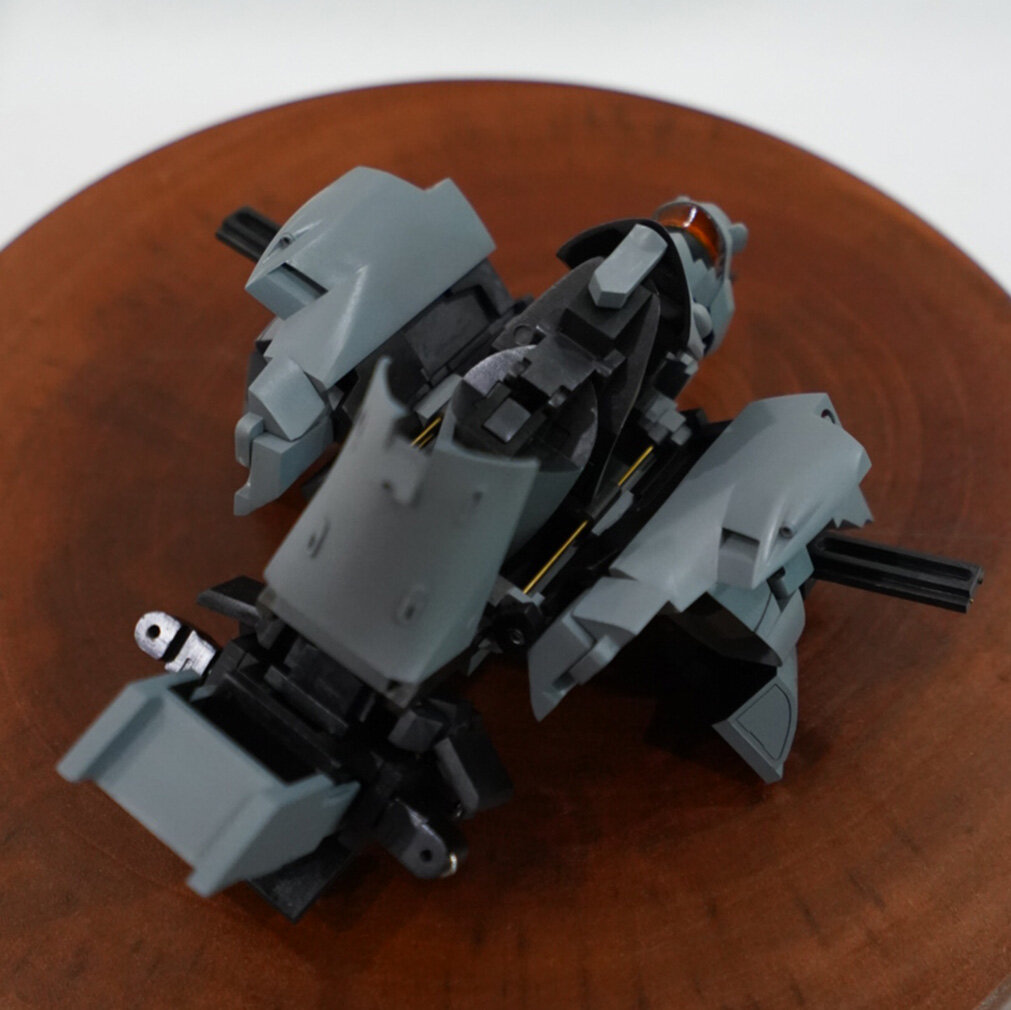

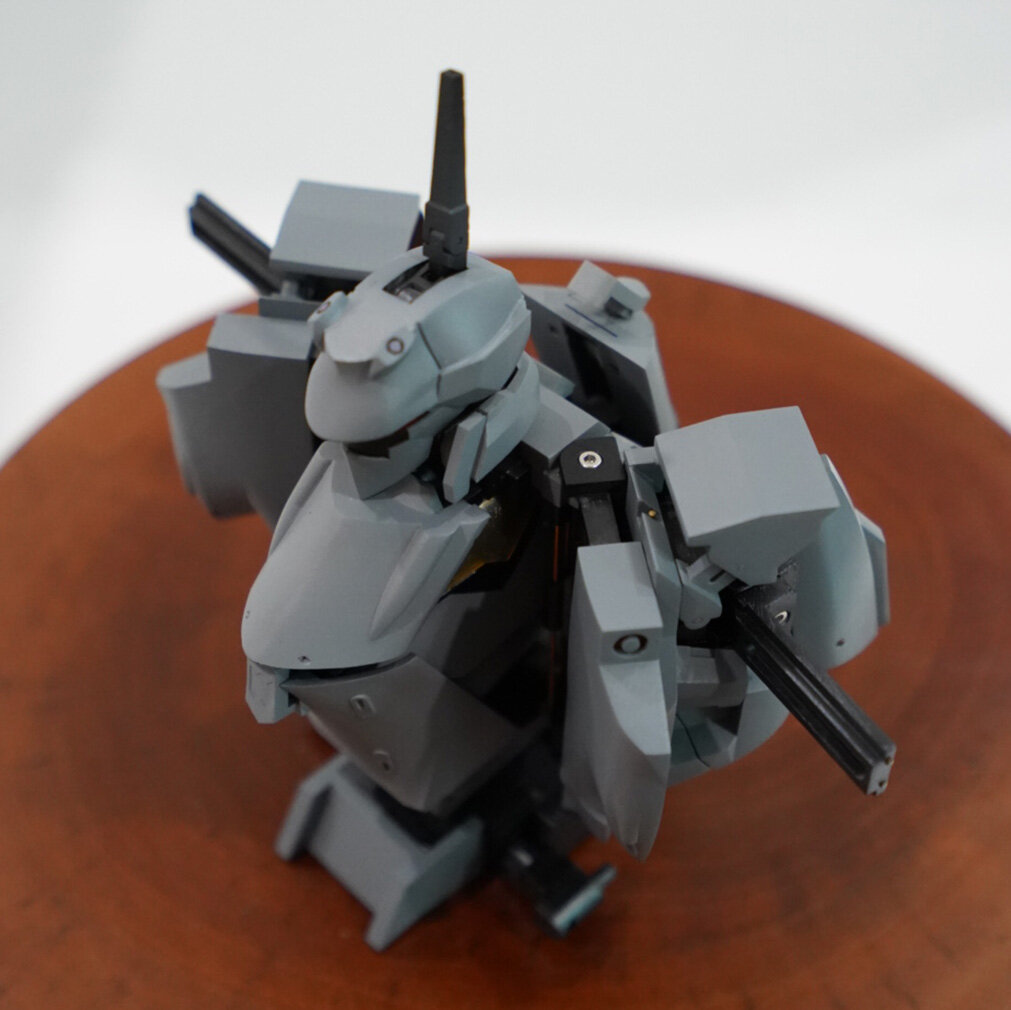

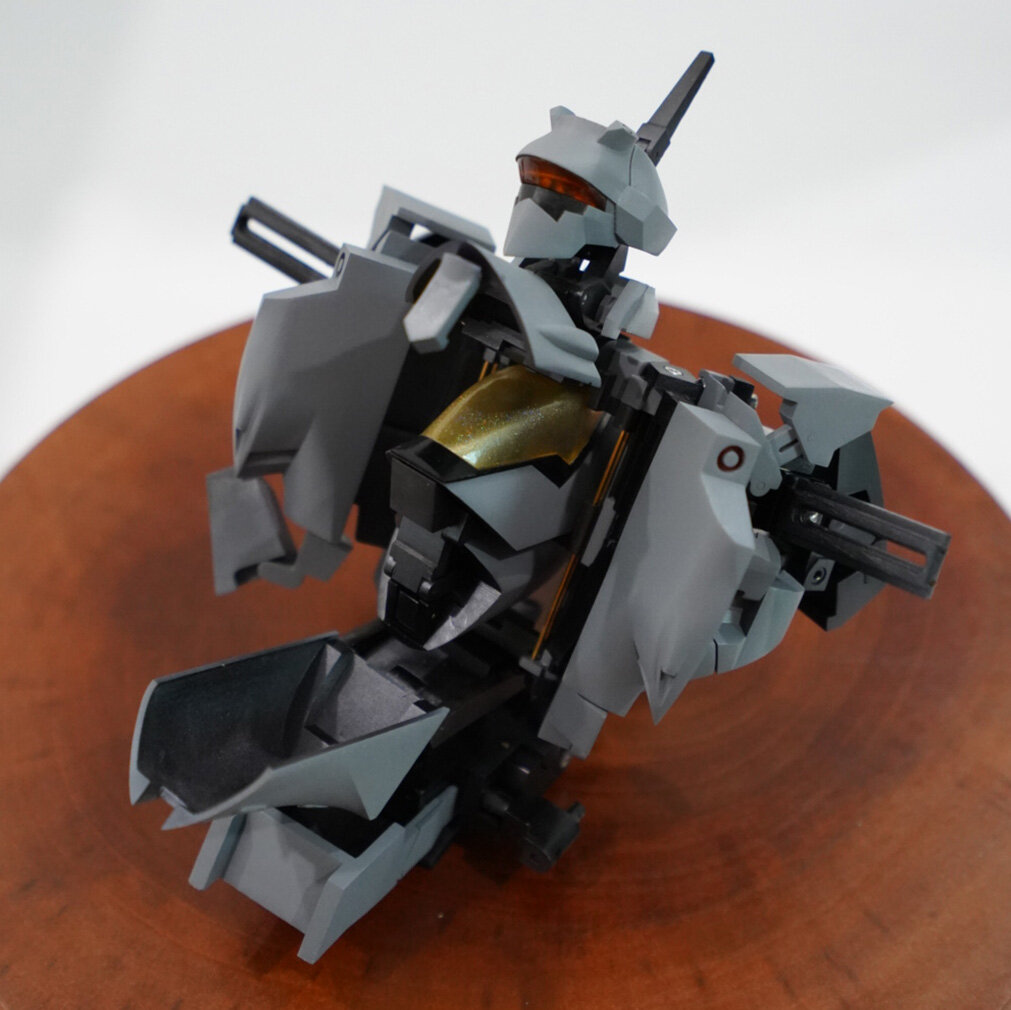

Hanger and Dive Mode. Some parts amended for better poses and Fast, Heavy Pack Attachment. 頑張ってよ! y6G20wGRBXY5y5Hq.mp4 pWKN-8cX_GqOjJBE.mp4

-

https://youtu.be/Nws6t_mvaWg

-

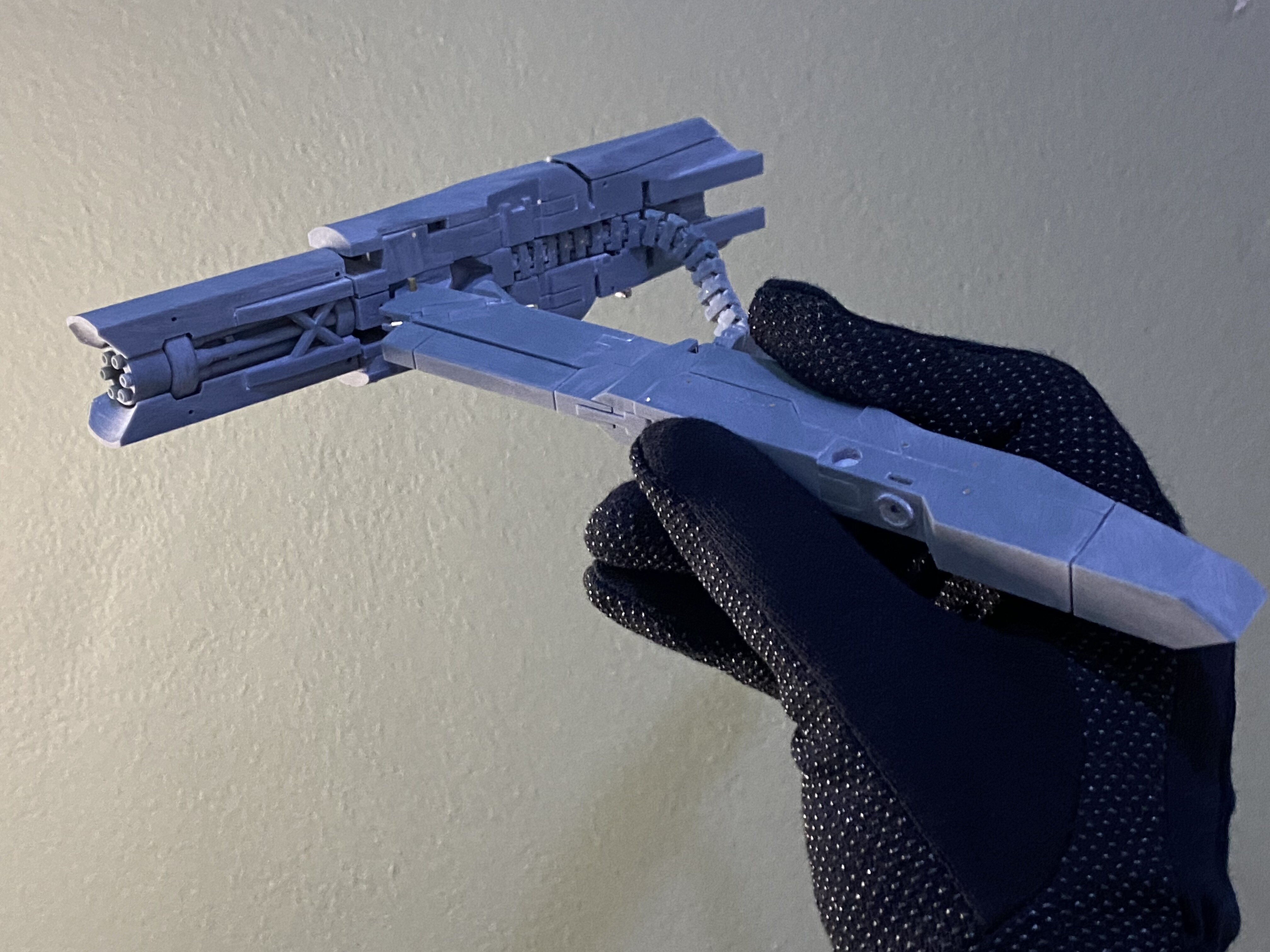

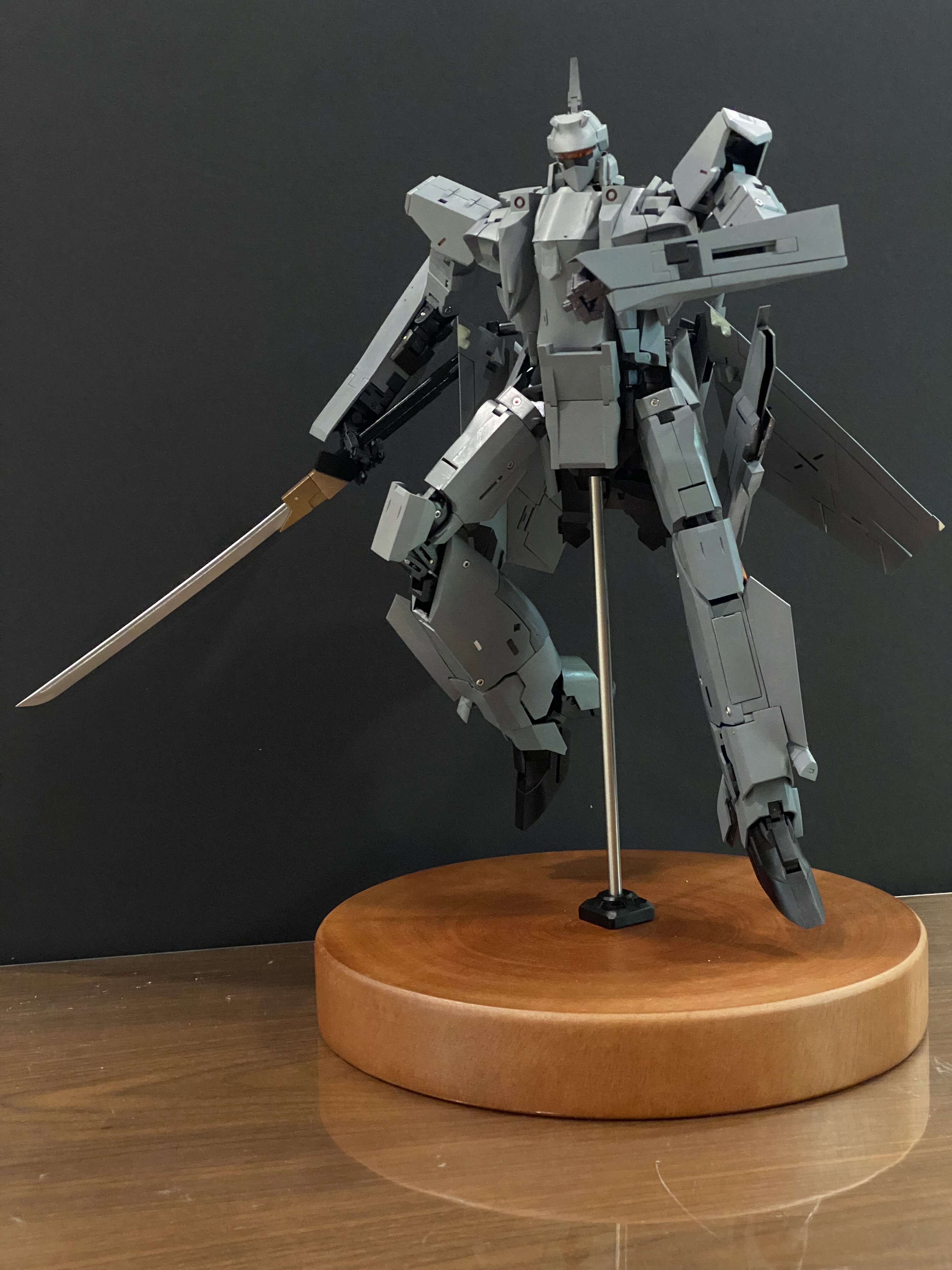

Hi, @Knight26 . I'm curious about this, too. What paint schemes will the community apply? Hi @djivaldi7 @rematron, I'm currently waiting for the metal parts. we are not able to accept any orders yet. I plan to make it into a half-assembled plastic model kit with a metal inner frame, parts, abs, and equivalent materials. Current 3D printed materials are not good enough. Major problems are weight and durability. Hi @Bolt @Mommar Thank you! appreciated! Hi @F18LEGIOSS2 , I applied a layer of matt coating on it, but there are still a few areas where the paint is scratched between parts. Hi @DownIsUp, At the current stage, the whole thing is built using resin, which is not great at transforming it into 3 forms. It is too heavy for my preference, and I can't overtighten some parts. Rubber-type resin won't break easily but will stretch over time and deform. I'm getting those parts printed in metal, which will properly solve the issue. For production, I will have to make it into plastic kits with metal inner frames and choose more durable materials for end-user products.

-

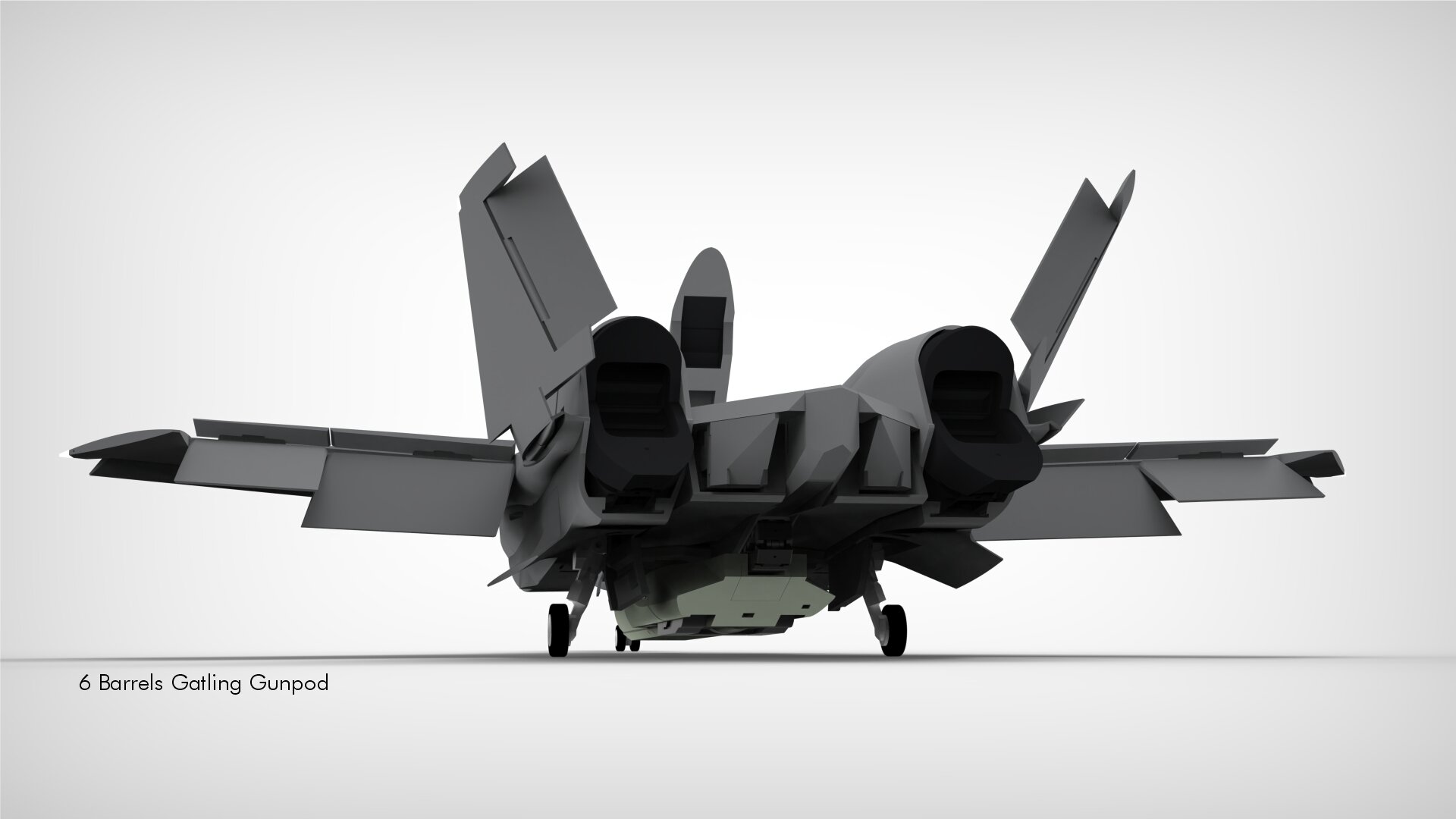

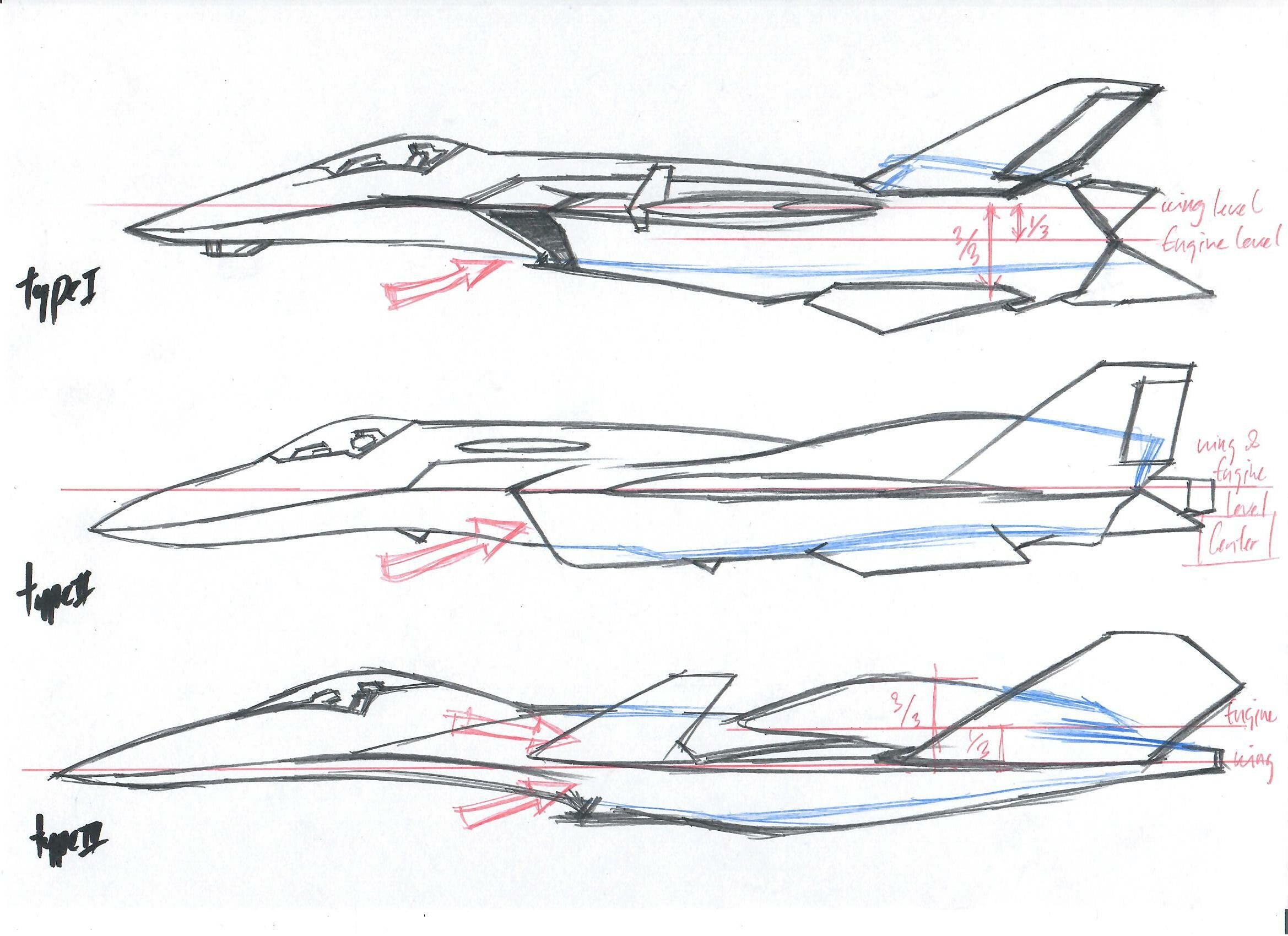

Hi, Good Idea but I have taken cockpit seat measurement to fit 5'6" to 6'8 figure into early stage of my six VF design, each type has its own unique seat design and pilot suits. some crucial specifications of design and making these VF i set myself are 1/48 (perfect scale for materials i choose for my prototype, easy for maintenance, no ball joint on arms, legs etc. except battroid head (Neck), no parts swapping, no anime magic transformation, Full transformation, flyable when i build a RC plane out of it with cg same as or close to (at least in RC build later type 02 & Ansys Fluid analysis) nature of my work as an engineer..lol curiosity and how far each design able to reach it max potential, Engine placement, arms, parts transformation (distance, weight, etc. , electronics, radar, sensors, etc. must at least seems to be functionable/workable/buildable like if we scale up to 1/1, all those stuffs could place into it, a 1/48 model toys which have the feel of a 1/1 model.

-

Thank you, bro. Hopefully, next year I'm able to join Wonder fest Japan

-

-

Hi Twich, The silhouettes of this type One and Type Two are mostly inspired by YF 21, VF 25, VF 1, F 35, F 18, YF 23 Black Widow II, ADF-01 (Ace Combat)

-

Thank you! Appreciated Yes, it's a magnetic ratchet ^^

-

Hi Shawn, do you mean this 3D-printed resin version? Is it a completed model or a garage kit you prefer most?

-

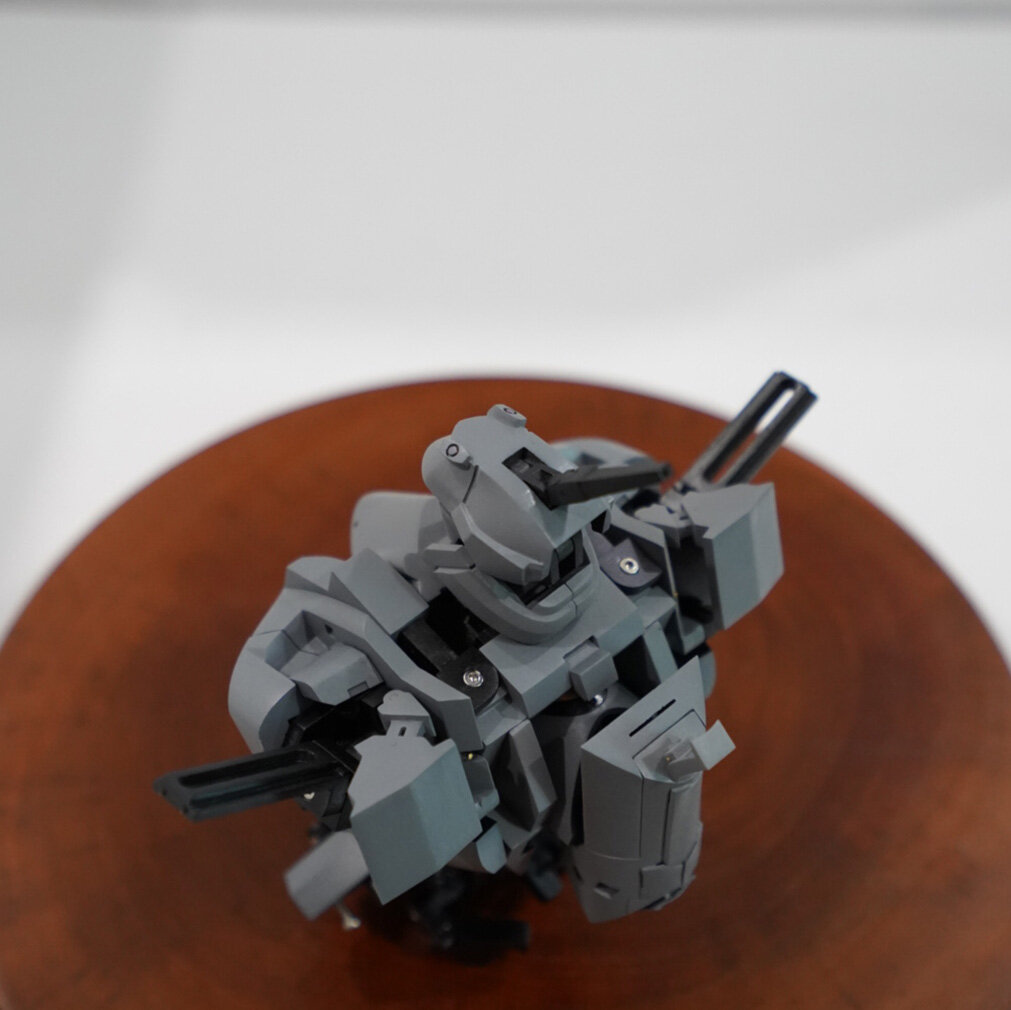

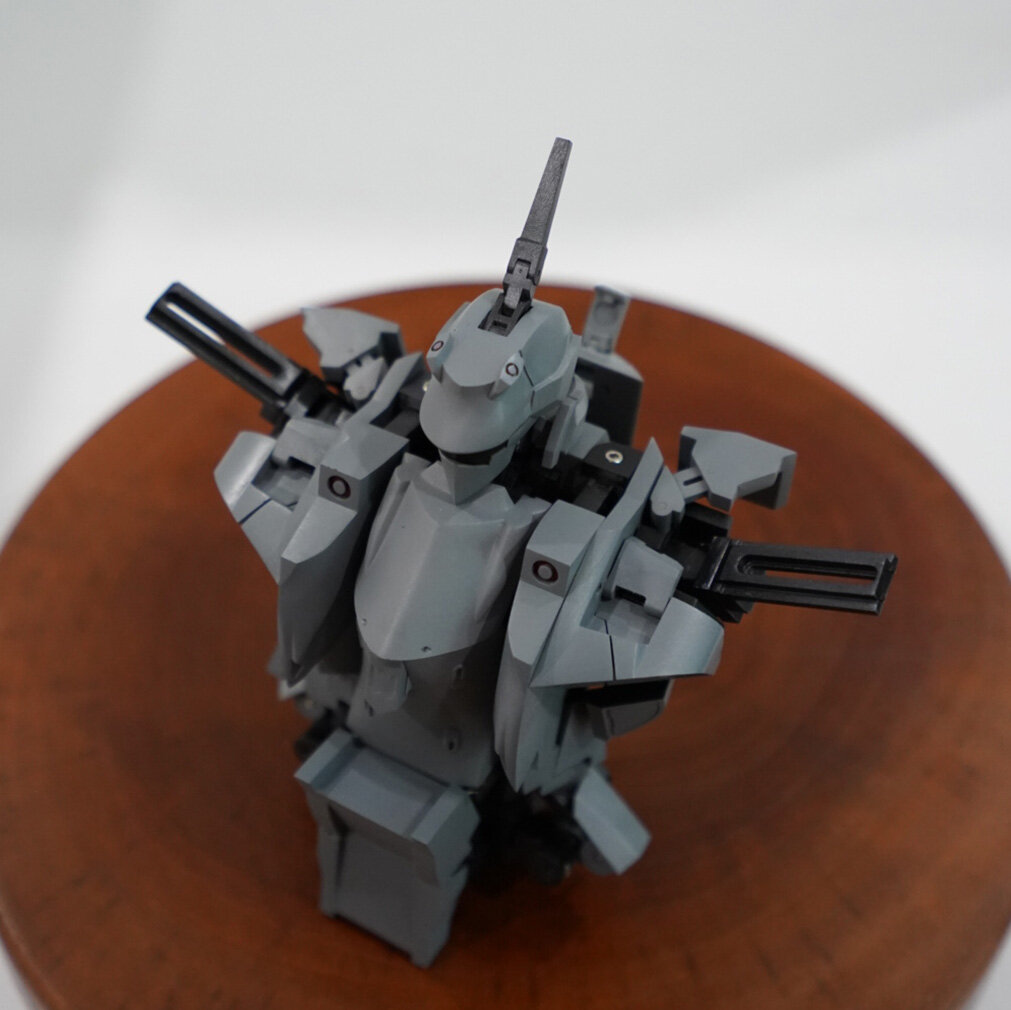

Type 01 [Designed in 2017-Core transformation parts amended in 2023 and 3D Resin printing in progress] & Type 02 [Painting in progress].

-

Hi, thank you. Initially planning to commercialize it, but it seems to be too soon and has a few uncertainties. my bucket list is to meet SenSei Shoji Kawamori if possible and present him with my work. Meet the person who inspired me to get into design VF and Engineering. After that then plan to commercialize it and maybe short animation after that. Those are childhood dreams of mine. Currently I'm waiting for a quotation from JLC3DP, some metal parts printing from them. And update you sir after i have the full parts listing price. Thank you

-

Thank you!