-

Posts

148 -

Joined

-

Last visited

About ImChris5115

- Birthday 06/01/1983

Profile Information

-

Gender

Male

-

Location

Japan

-

Interests

Mechanical Design

Recent Profile Visitors

1056 profile views

ImChris5115's Achievements

Destroid Armour Waxer (3/15)

302

Reputation

-

@no3Ljm @rematron @Test_Pilot_2 @twich @M'Kyuun Thanks guys, appreciated!

-

Hi @no3Ljm, That's a cool video you shared there. I'm sorry, man. I wish I had experience using 3D Max, Maya, or Blender to do 3D animation. I know how to create 3D designs using CAD software like NX, Solidworks, and AutoCAD. But I'm only able to create exploded views and parts animation. I totally have no skillset in VFX and animation shown in this video. I admire those talents who are able to create something like that.

-

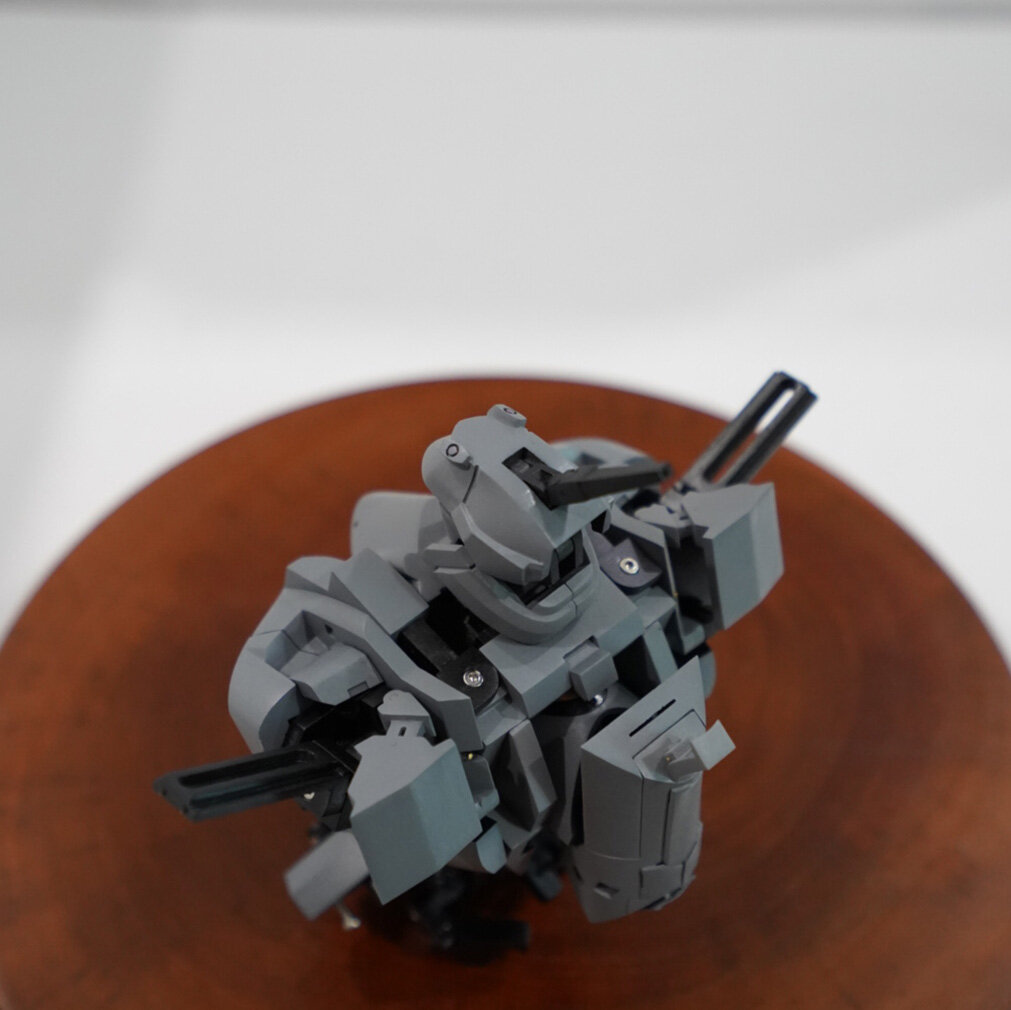

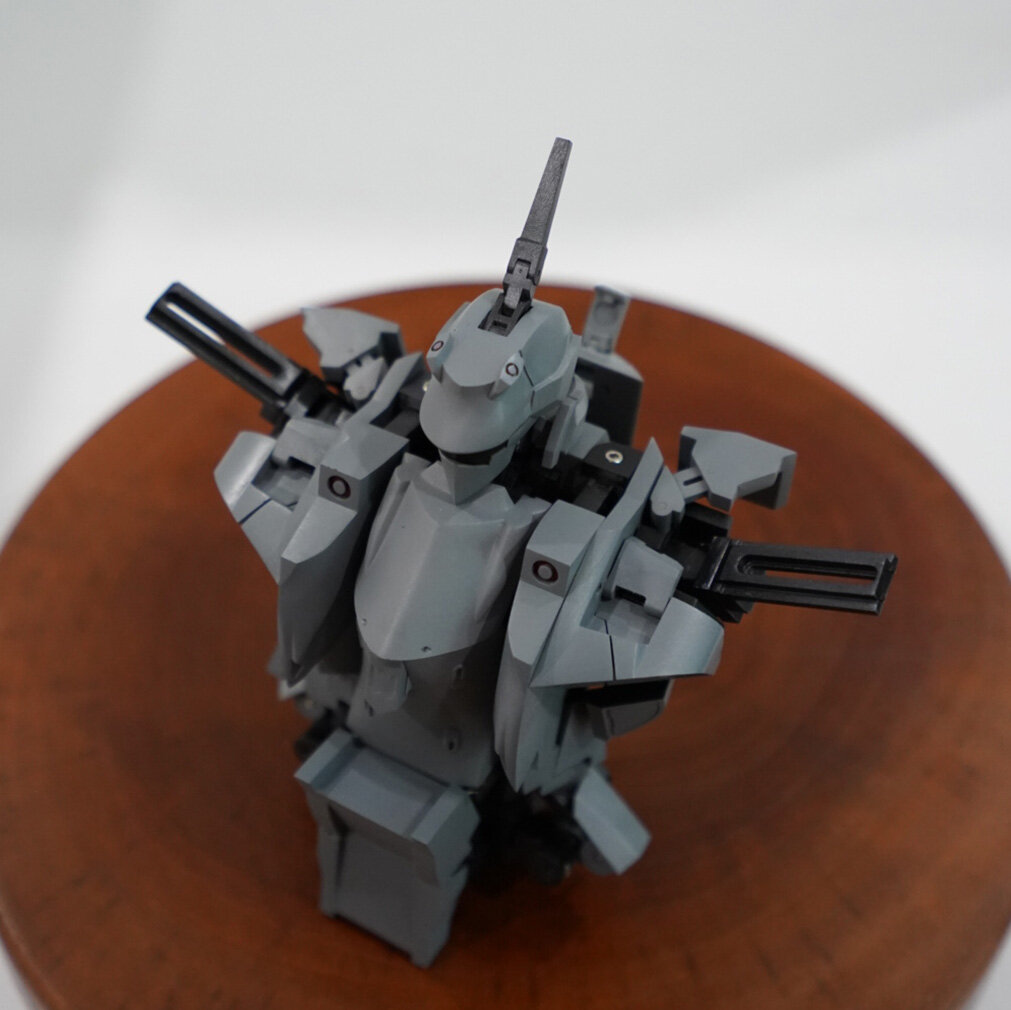

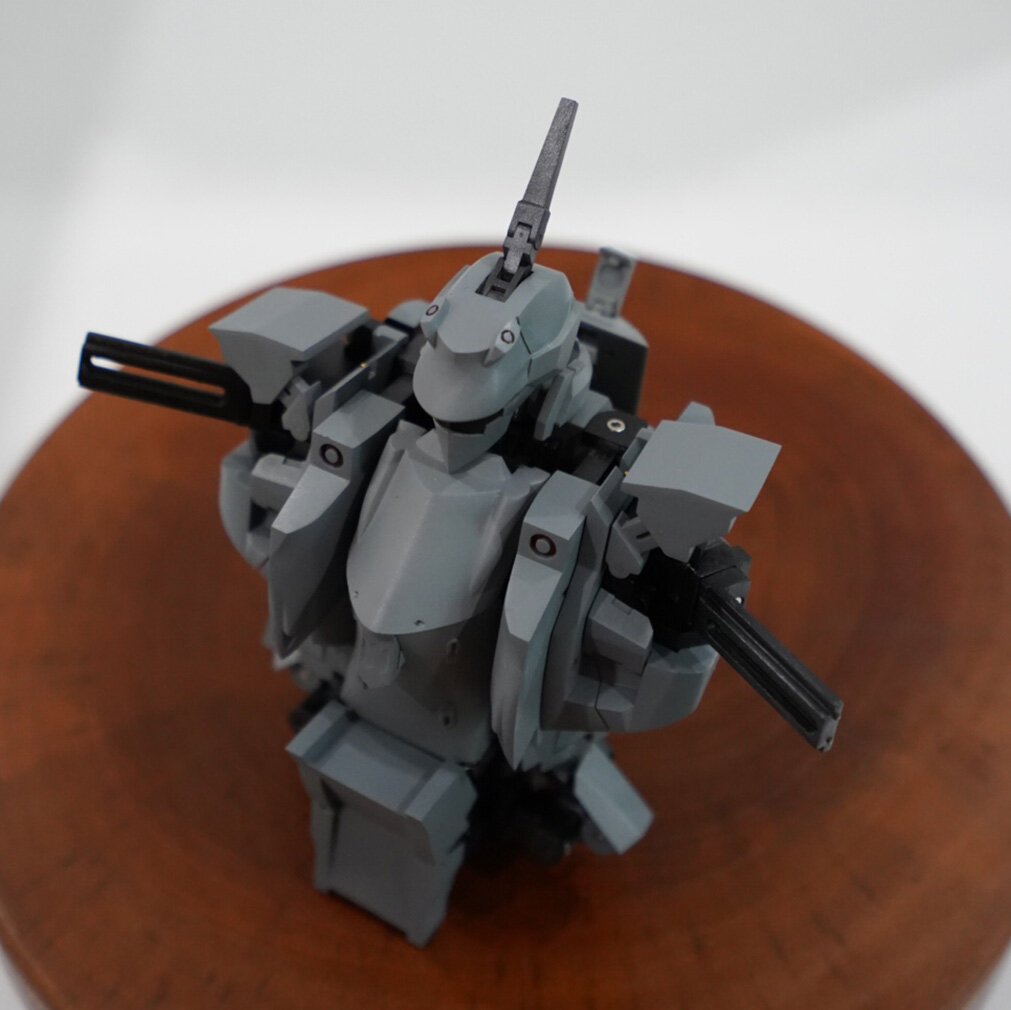

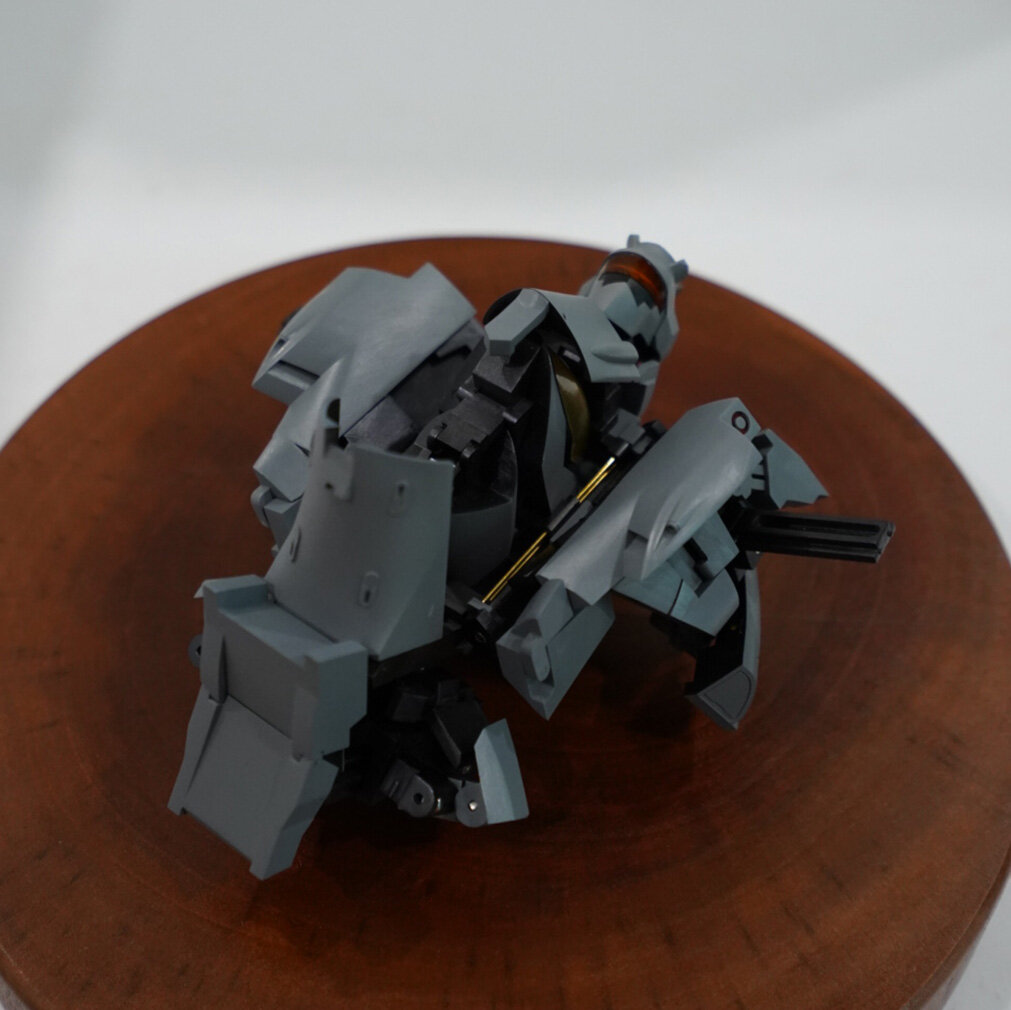

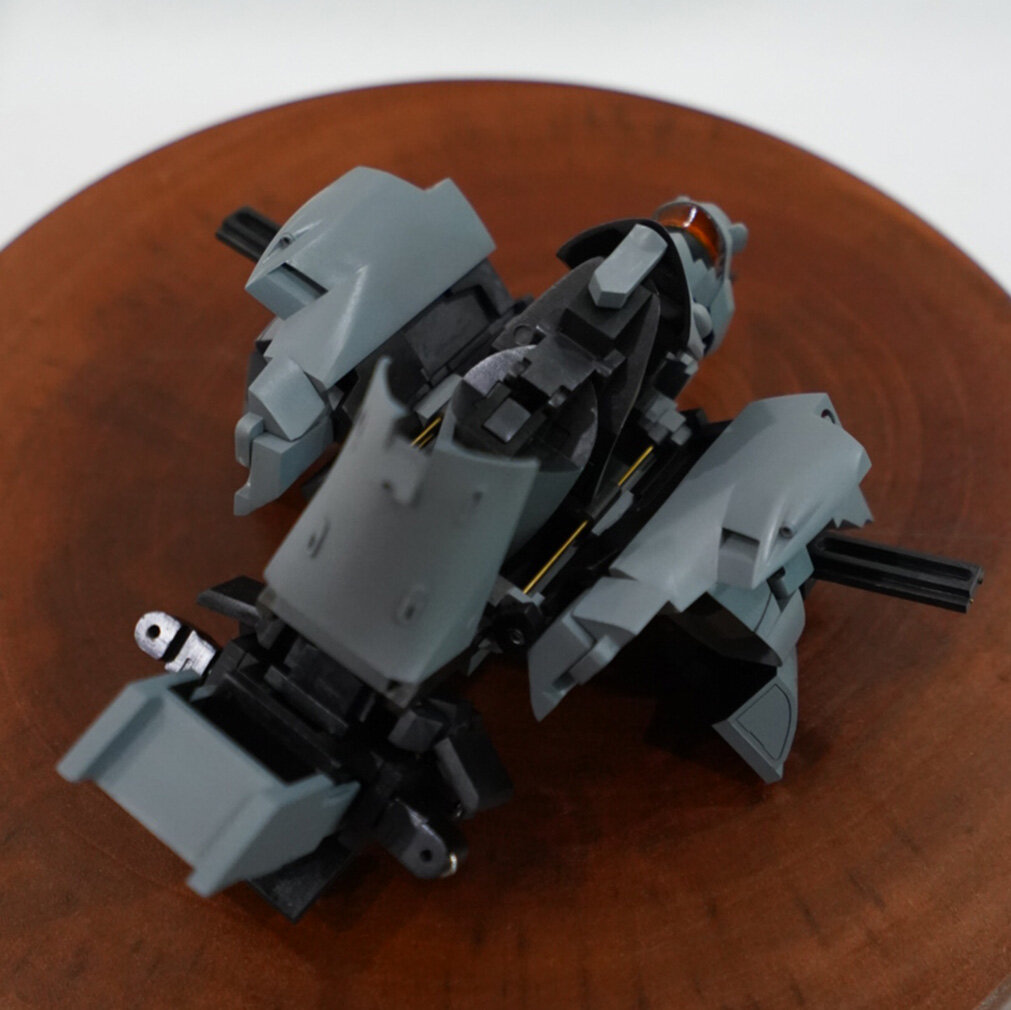

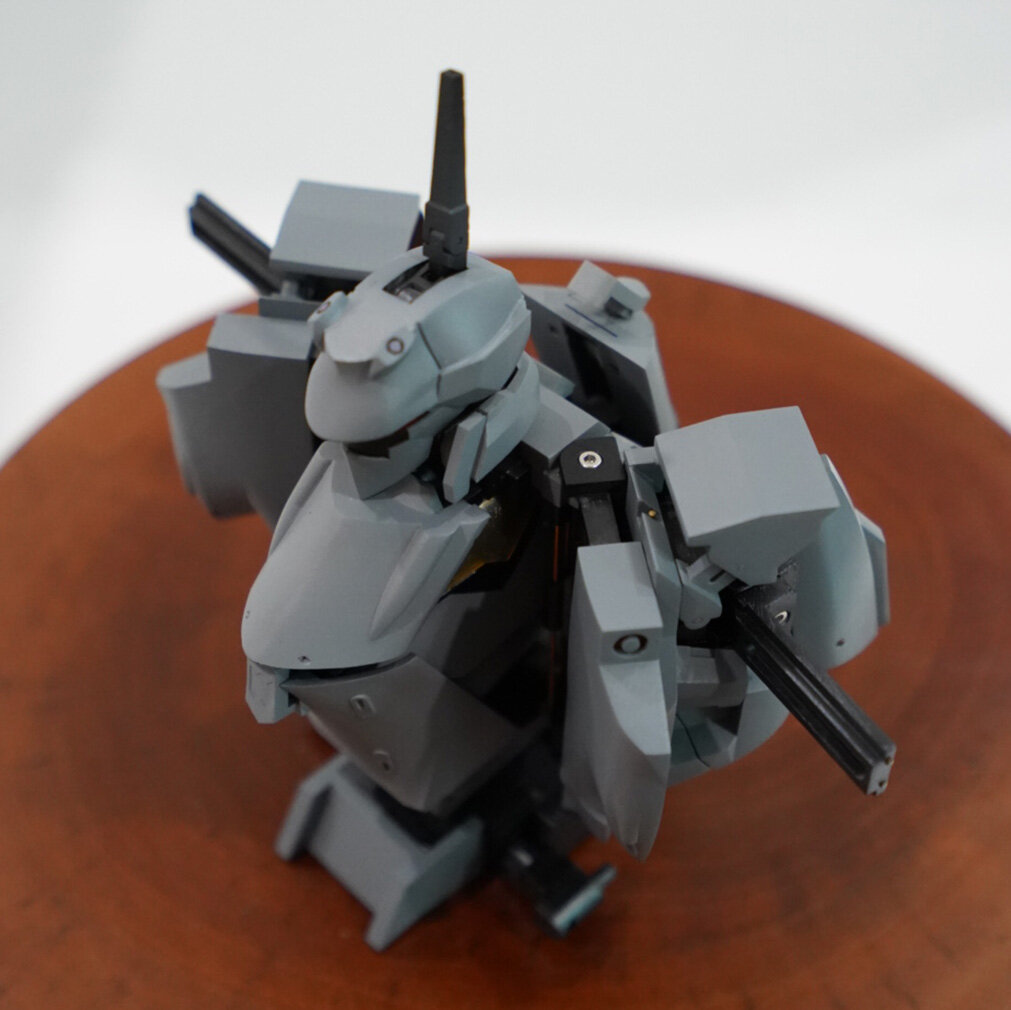

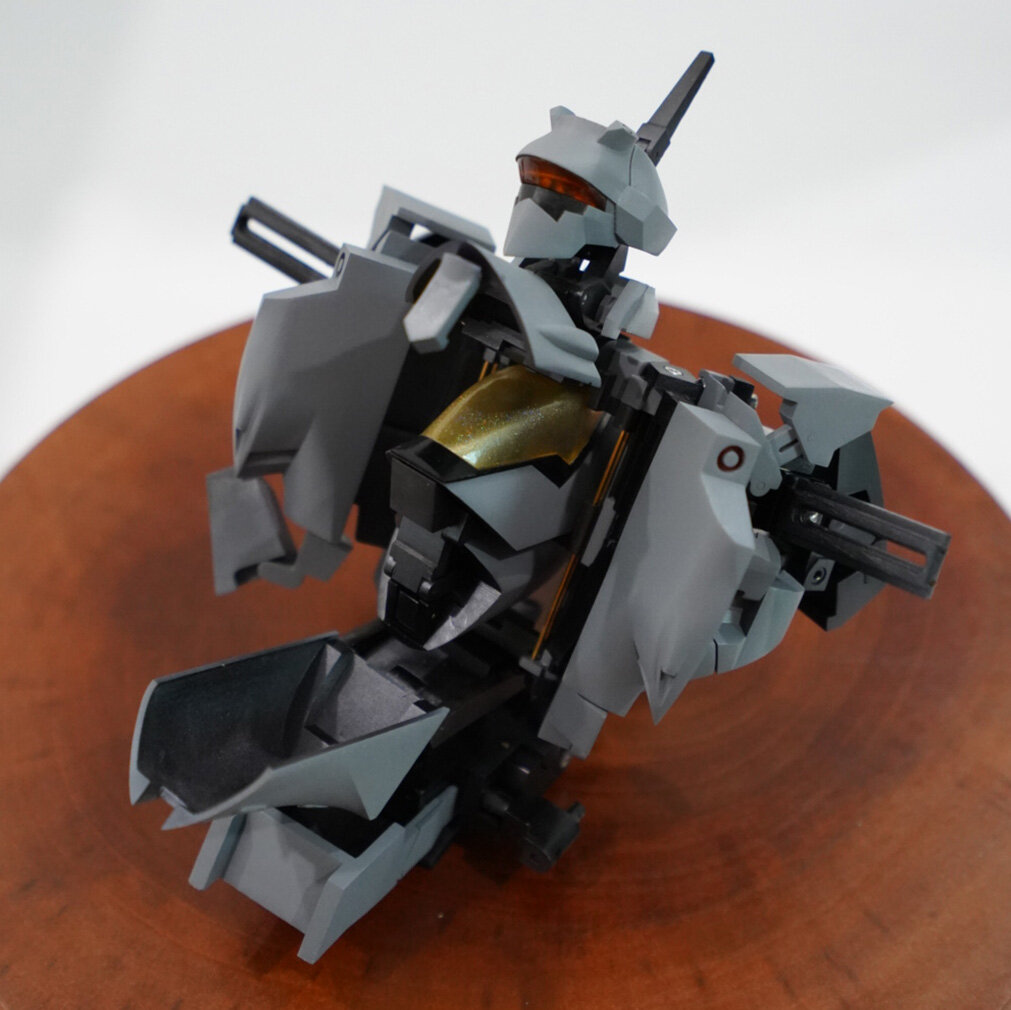

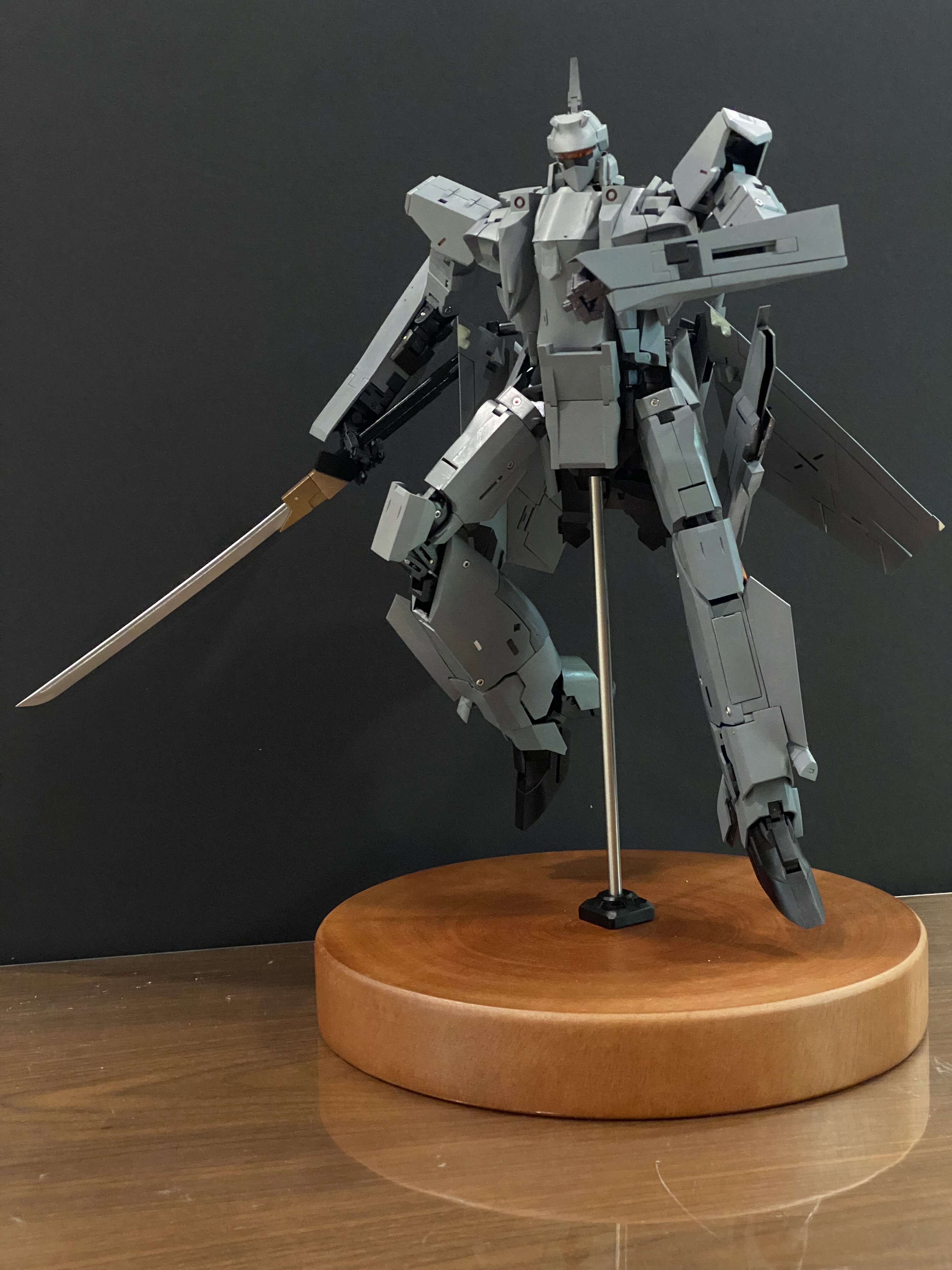

Hanger and Dive Mode. Some parts amended for better poses and Fast, Heavy Pack Attachment. 頑張ってよ! y6G20wGRBXY5y5Hq.mp4 pWKN-8cX_GqOjJBE.mp4

-

https://youtu.be/Nws6t_mvaWg

-

Hi, @Knight26 . I'm curious about this, too. What paint schemes will the community apply? Hi @djivaldi7 @rematron, I'm currently waiting for the metal parts. we are not able to accept any orders yet. I plan to make it into a half-assembled plastic model kit with a metal inner frame, parts, abs, and equivalent materials. Current 3D printed materials are not good enough. Major problems are weight and durability. Hi @Bolt @Mommar Thank you! appreciated! Hi @F18LEGIOSS2 , I applied a layer of matt coating on it, but there are still a few areas where the paint is scratched between parts. Hi @DownIsUp, At the current stage, the whole thing is built using resin, which is not great at transforming it into 3 forms. It is too heavy for my preference, and I can't overtighten some parts. Rubber-type resin won't break easily but will stretch over time and deform. I'm getting those parts printed in metal, which will properly solve the issue. For production, I will have to make it into plastic kits with metal inner frames and choose more durable materials for end-user products.

-

ImChris5115 changed their profile photo

-

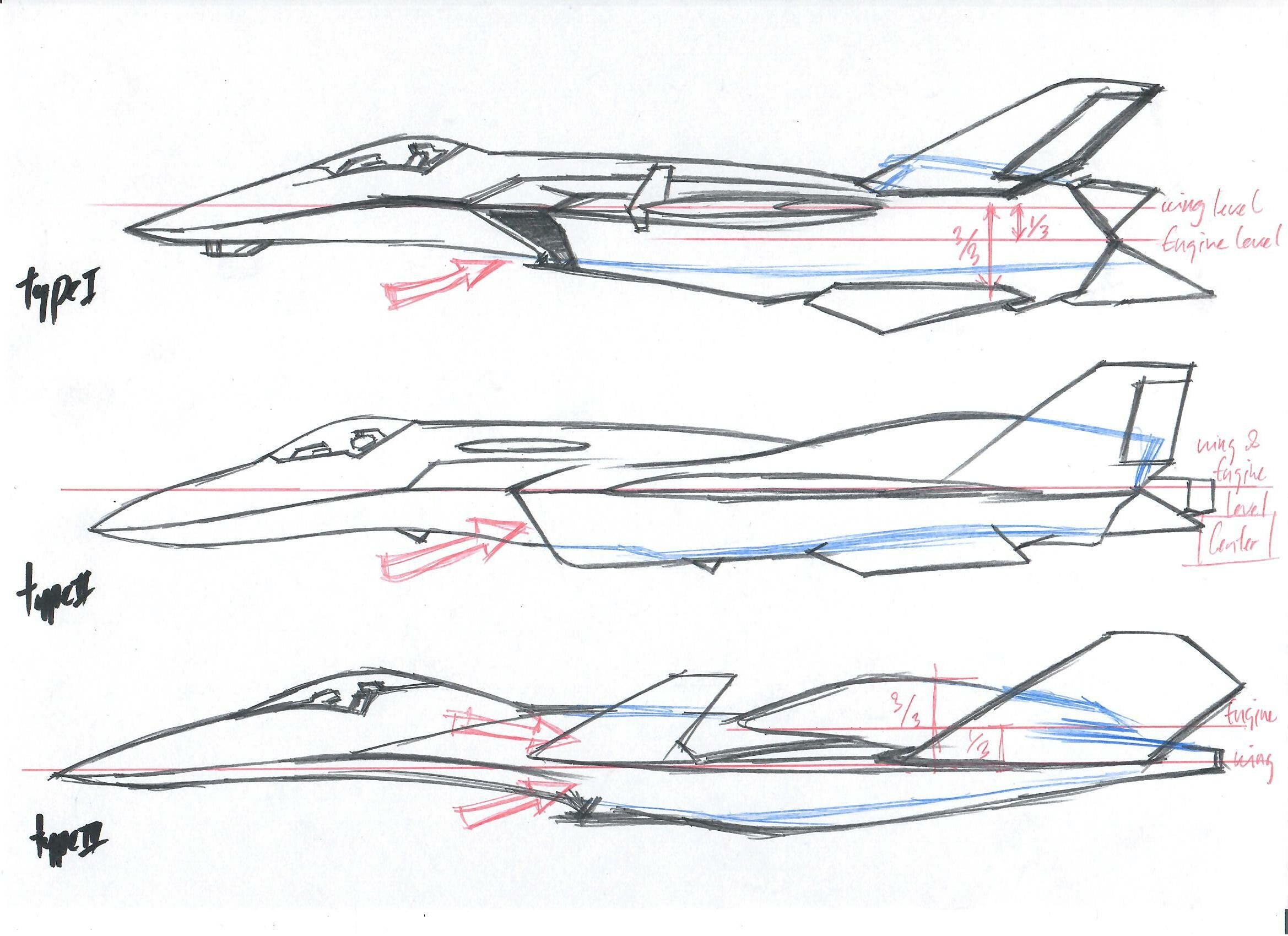

Hi, Good Idea but I have taken cockpit seat measurement to fit 5'6" to 6'8 figure into early stage of my six VF design, each type has its own unique seat design and pilot suits. some crucial specifications of design and making these VF i set myself are 1/48 (perfect scale for materials i choose for my prototype, easy for maintenance, no ball joint on arms, legs etc. except battroid head (Neck), no parts swapping, no anime magic transformation, Full transformation, flyable when i build a RC plane out of it with cg same as or close to (at least in RC build later type 02 & Ansys Fluid analysis) nature of my work as an engineer..lol curiosity and how far each design able to reach it max potential, Engine placement, arms, parts transformation (distance, weight, etc. , electronics, radar, sensors, etc. must at least seems to be functionable/workable/buildable like if we scale up to 1/1, all those stuffs could place into it, a 1/48 model toys which have the feel of a 1/1 model.

-

Thank you, bro. Hopefully, next year I'm able to join Wonder fest Japan

-