-

Posts

62 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Bushwood3006

-

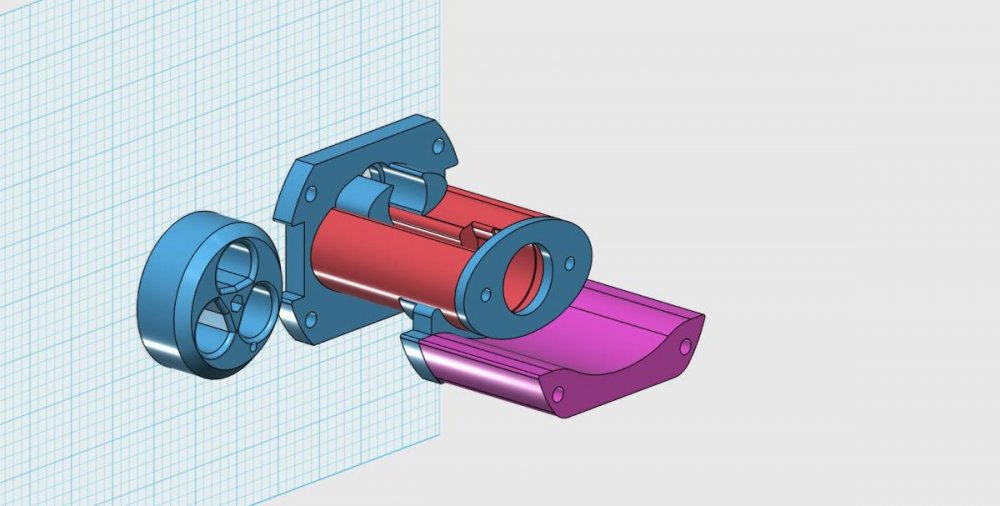

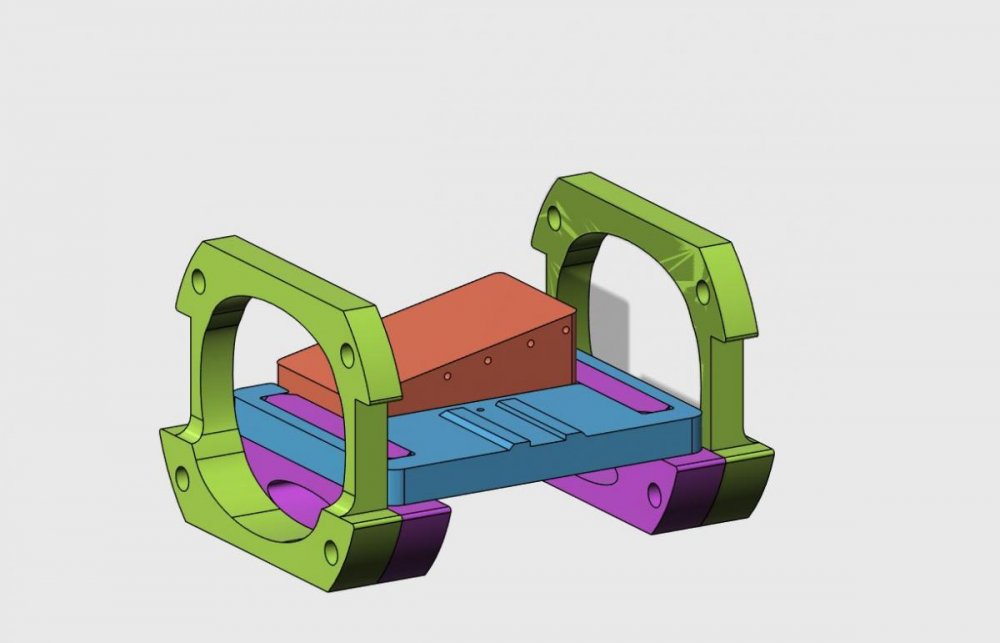

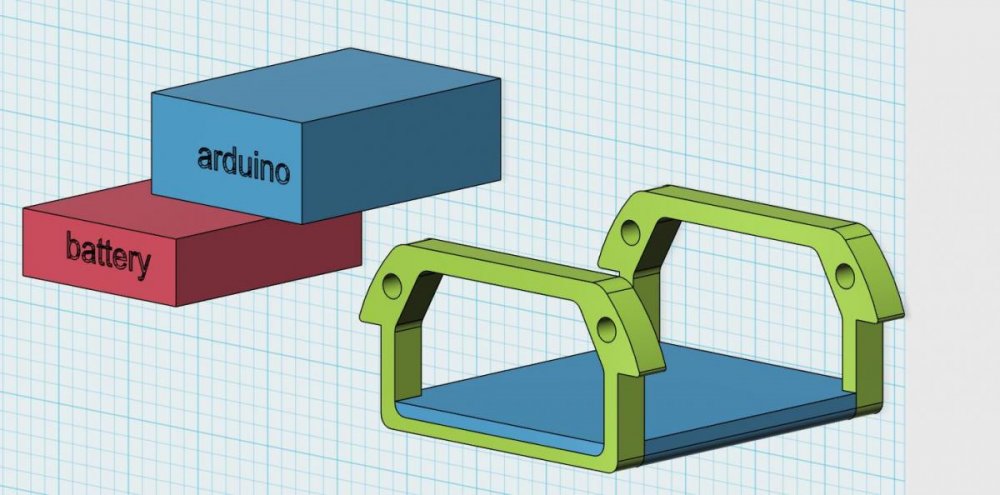

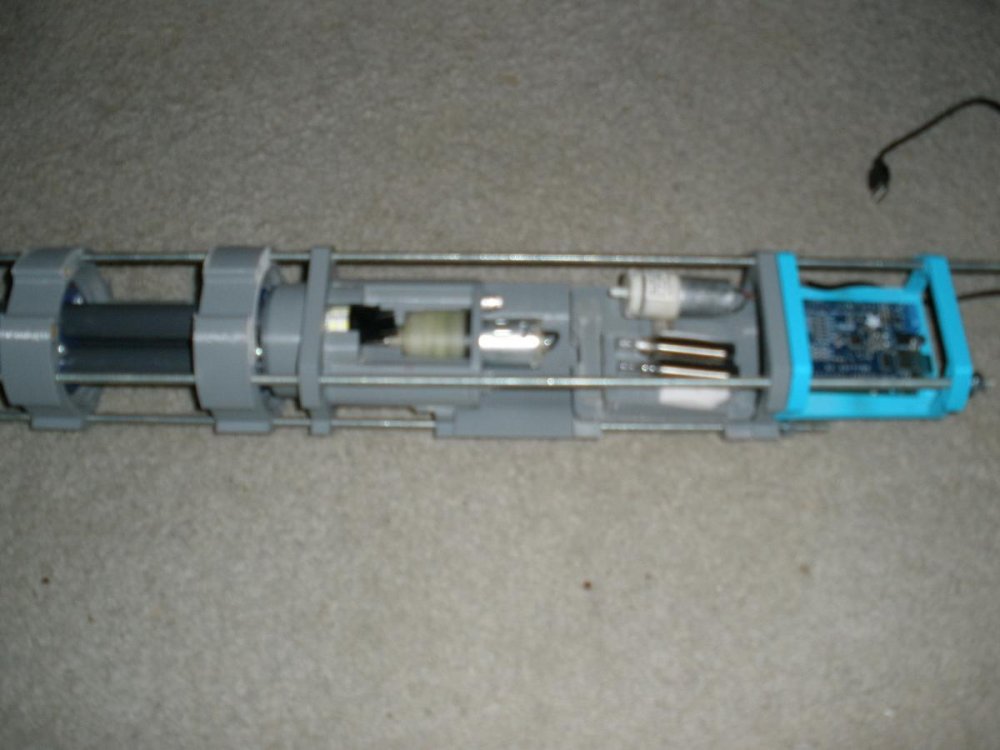

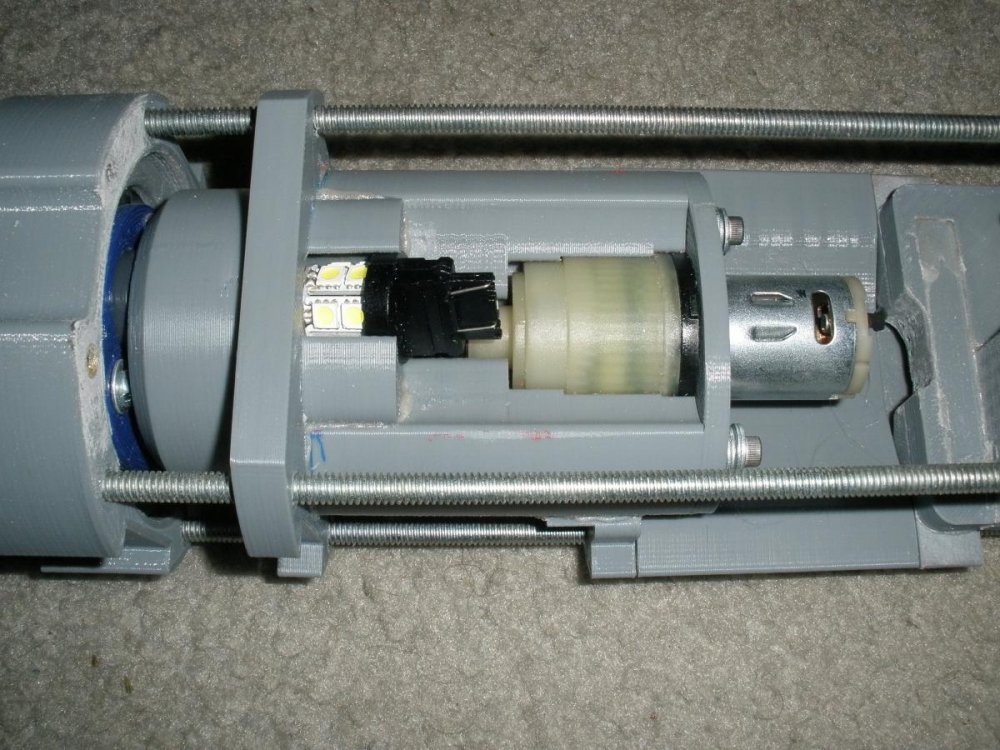

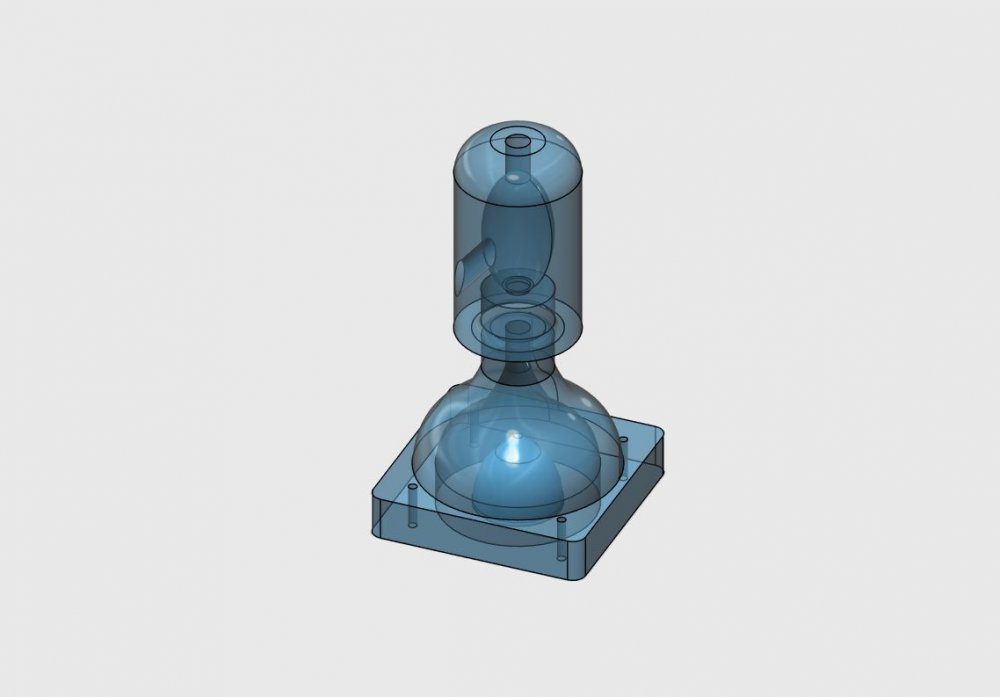

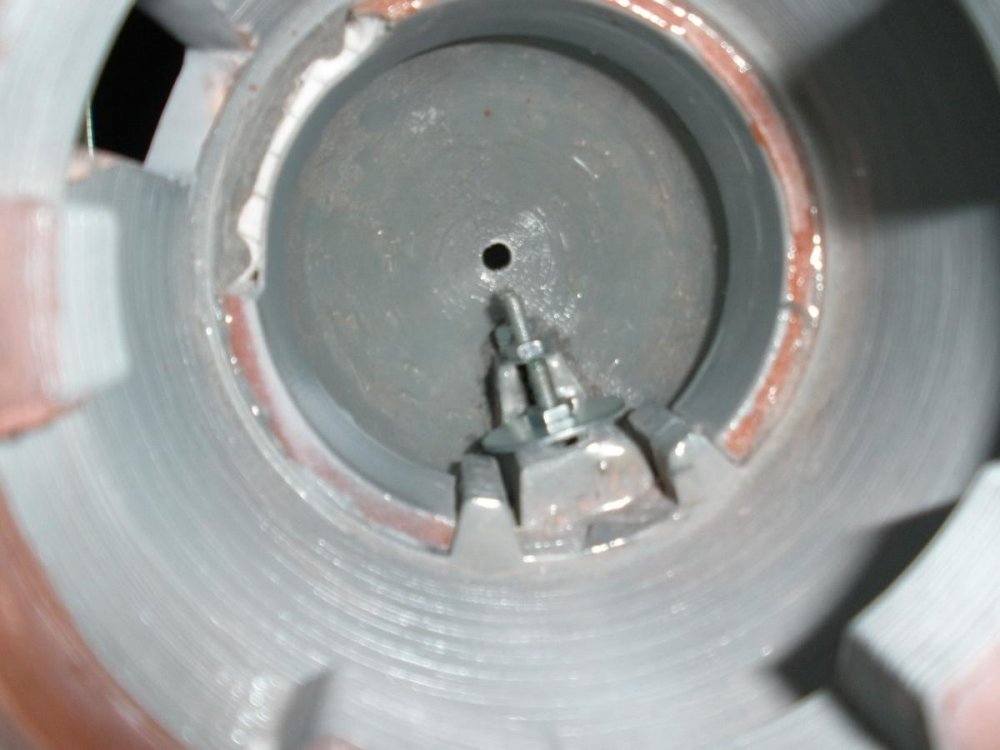

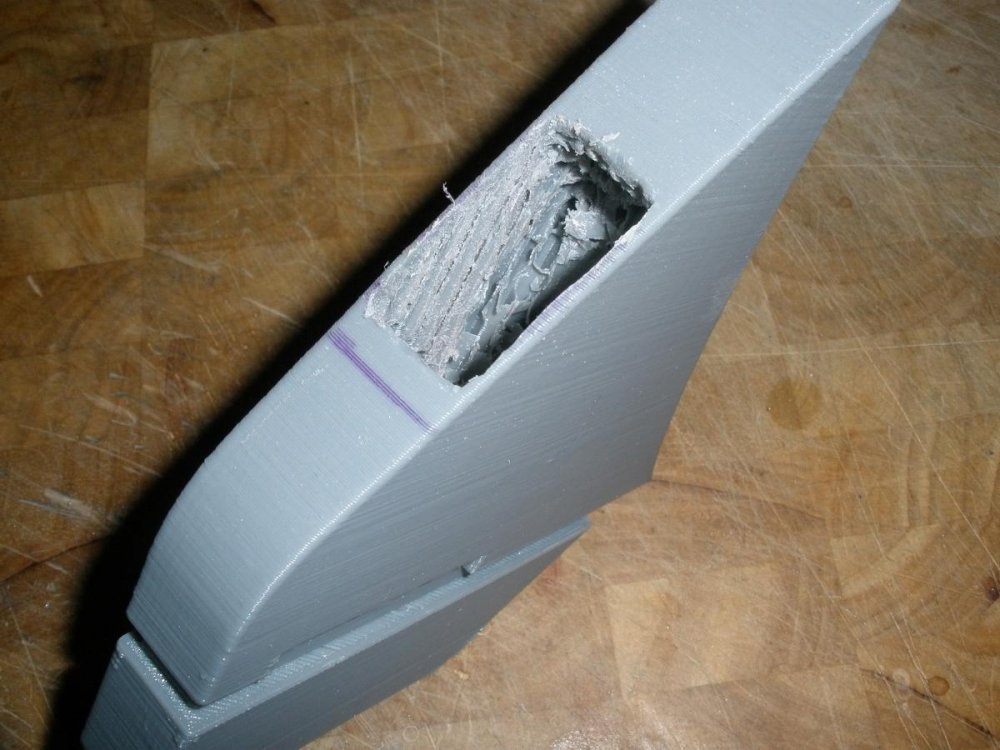

Been a while since my last update, Been tinkering, finally found a motor that works for the smoke generator, But it literally was on the slow boat from China. (I didn't look at the sellers location before I ordered it) The CADS for the guts. They will just stack up on 1/4" threaded rod Motor/ light mount, Smoke generator Arduino section All mocked up, Using a spare LED brake light, and a motor/gearbox from a cordless screw driver, 1 or 2 Vape pens running of a 12 air pump, and the arduino with sound shield( still needs mounting brackets) Also got the trigger setup, Made a quick 3d print to get a close template then make the actual thing out of layered styrene to get the shape of the cam for the micro switch right Got the micro switch mounted int the grip. I cut a wide grove in the grip on used a doubled up copper plate and back filled it with epoxy putty.

-

Well got all the electronics in this week. Good think i watched some youtube vids on arduino. Everything i want to run off the boards exceeds the current limits for all the pins. But quickly solved, got a pack of transistors on order. The CPU fan and duct idea for the smoke generator however is a total fail. I was hoping it would act like a airbrush and siphon smoke from the e-cig tip, but with 1/4 airline tubing it just builds back pressure and blows the smoke out the wrong side of the e-cig.

-

Unless someone knows of a gunsmoke flavored vape juice..... I went with Coffee

-

a small computer fan, and ill 3d print a funnel to manifold it all up.

-

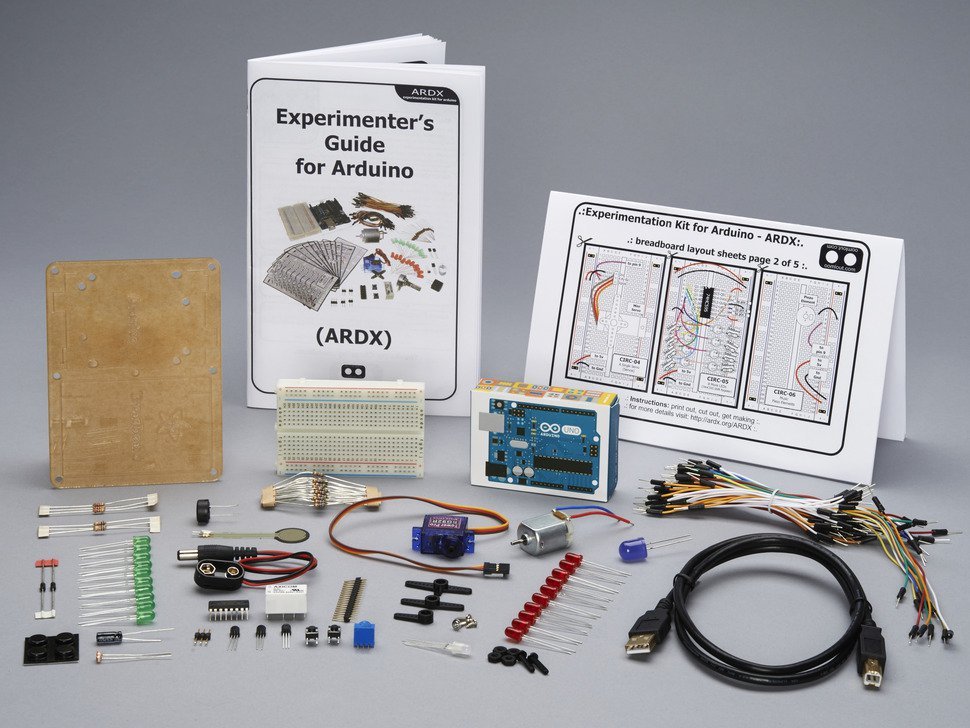

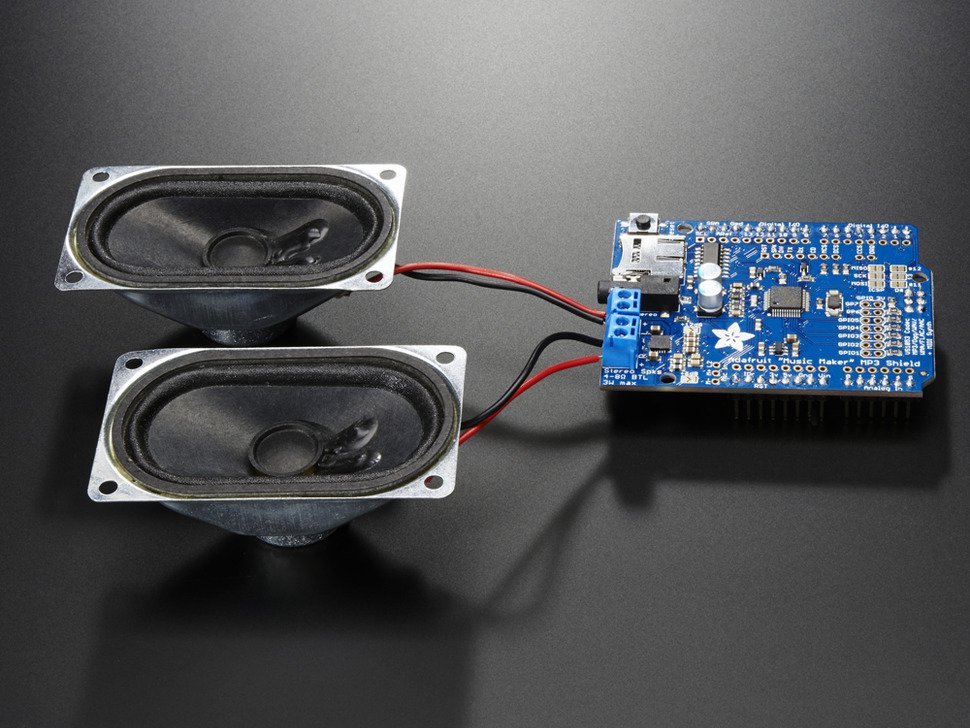

Both buttstock pieces are full assembled. I think ill leave it as a 2 piece assembly. The friction fit between the two is pretty snug and secure. The lower (sling mounting) fin is also bolted on for extra strength. All the body pieces are now primed. I had to do some re-work on the buttstock. I use some bandage wrap with epoxy coating to bulk up the outer diameter, faster. which worked great....... as long as I don't leave the thing out in the Florida heat. In some areas it hasn't reacted well and softened the epoxy so I had to cut out and bondo the soft spots, and re-prime. Also bought most of the electronics. Its all gonna run on a Arduino Uno & MP3 Shield, and a couple of E-Cigs for smoke generators. Along with some extra components. But 200 dollars worth of stuff total.

-

Before After priming Needs a few more coats to get rid of that porous texture Bondo leaves. Also using Dulpi-color primer now.

-

Thing is starting to look like a cannon now. Kinda stuck in the vicious " Prime, Fill, Sand....... Repeat " cycle at the moment. Note NEVER use rustoleum filler primer. That crap is garbage.

-

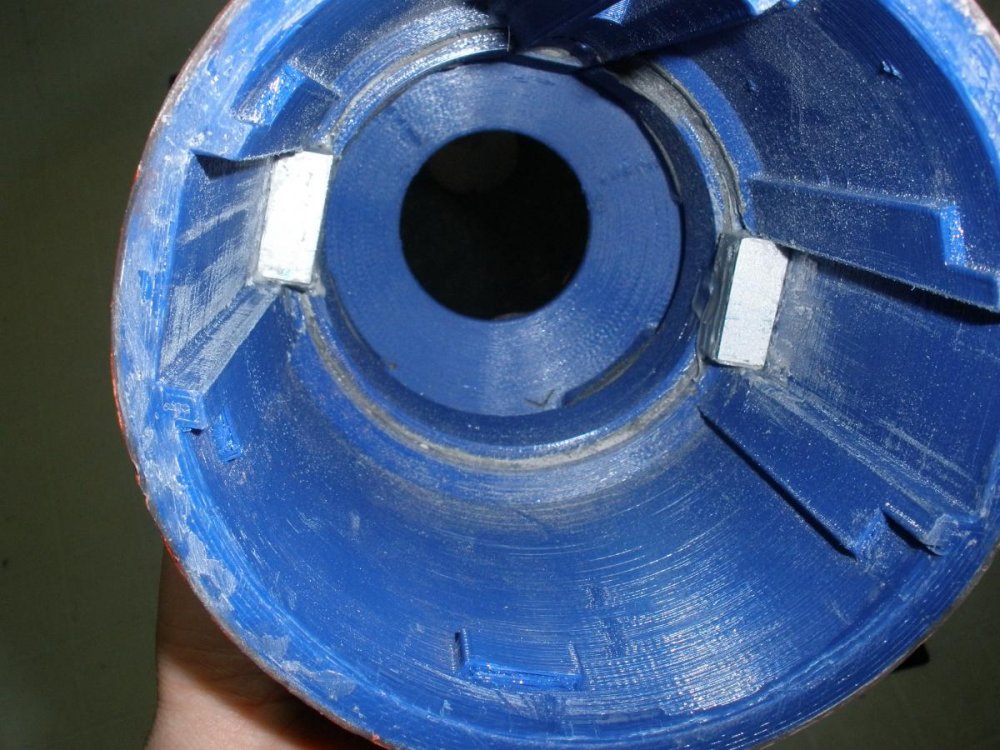

Got the chassis rails installed. Added magnets to each end and stops inside the muzzle to help hold it secure. Might be a bit over kill friction alone might be good enough to hole it on, got to use my feet to hold the body to pull it apart. Glad I still had some aluminum square tube hanging around. made for a perfect clamp.

-

So. Learned a valuable lesson. When using signs for a source of styrene. Remove the printing first then glue. It took forever for the solvents to off gas. But it gave me a chance to add more epoxy layers to the front and back cone so the all have about the same outer diameter. Now lots lots more sanding Yeaaaa. First layer glued with contact cement second layer glued on with testors glue end caps thickened

-

LOL Funny My V1 1A is yellowed on almost exactly the same parts.

- 8198 replies

-

- toys

- collectors

-

(and 22 more)

Tagged with:

-

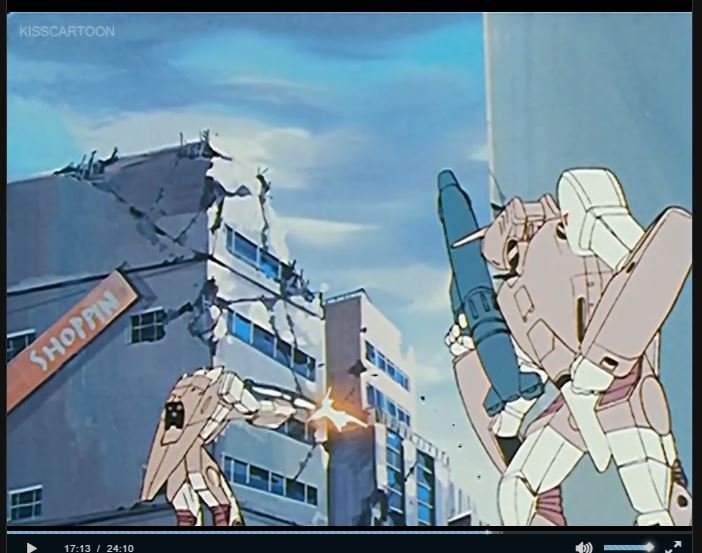

Crappy screen cap but you can see the arch of spent cases from the 1A on the left. (just a series pf black specks)

-

Not quite big enough for a complete .308, Which It should be big enough for a complete round. It is however big enough for a .50 Beowulf. I thought about making it eject spent cases, but it just would have used up too much space to make a magazine and something to force out the cases. Maybe next time.

-

Success!! It would appear that contact cement loves to bind to PLA. Not quite so much to styrene. But more than strong enough for my needs. I need to make a run to Walmart and pick up more. The small craft bottle did not go quite as far as I thought it would. Ignore the fact it's covered in "For Sale" signs...... Just a cheap source for large styrene sheets.

-

Just Got mine today. Even with part swapping I think it looks great. Only wish they included a couple more fillers, for the top of the shoulders @ the gun, and top of the leg when in attacker mode.

-

Ok soooo. After many, many, many hours of sanding( I put that JB-weld on way to thick). Finally got the point were I was ready to start skinning the main tube. I did a couple test with failed prints, and superglue worked awesome on the test pieces. Tried it in the main tube for real and not so much. Big Time Fail. Pieces are just too Big to do with super glue. Leaves too many air pockets and no bond areas. Peeled all that off, re-sanded and went with Plan B, Lock-tite brand spray Contact Cement. Sooo. fail number 2, (that crap doesn't bond to anything and it just makes a gummy mess like that crap they use to glue on address labels to magazines.) So I'm on plan C, Dap Weldwood. So far so good. i doesnt just peel off PLA or styrene when its dry. So got some test pieces glued up and gonna let them cure a while.

-

Been a while since last update. Sorry, fell in to a bit of an uber-lazy kick. Did a lot of filling and priming. A lot of parts were not at strait as I had hoped. But I think that was because a software/setting thing on my part Finished gluing up the main body. When I cleaned up all the excess on the seams I notices the segments were slightly staggered. Not by much but i would be noticeable. So my solution is a layer of JB-Weld over the whole thing and that will get sanded smooth. I'm not to worried it its not perfectly circular, just need to level all the high and low spots Also got the flutes and sensor lenses molded and cast.

-

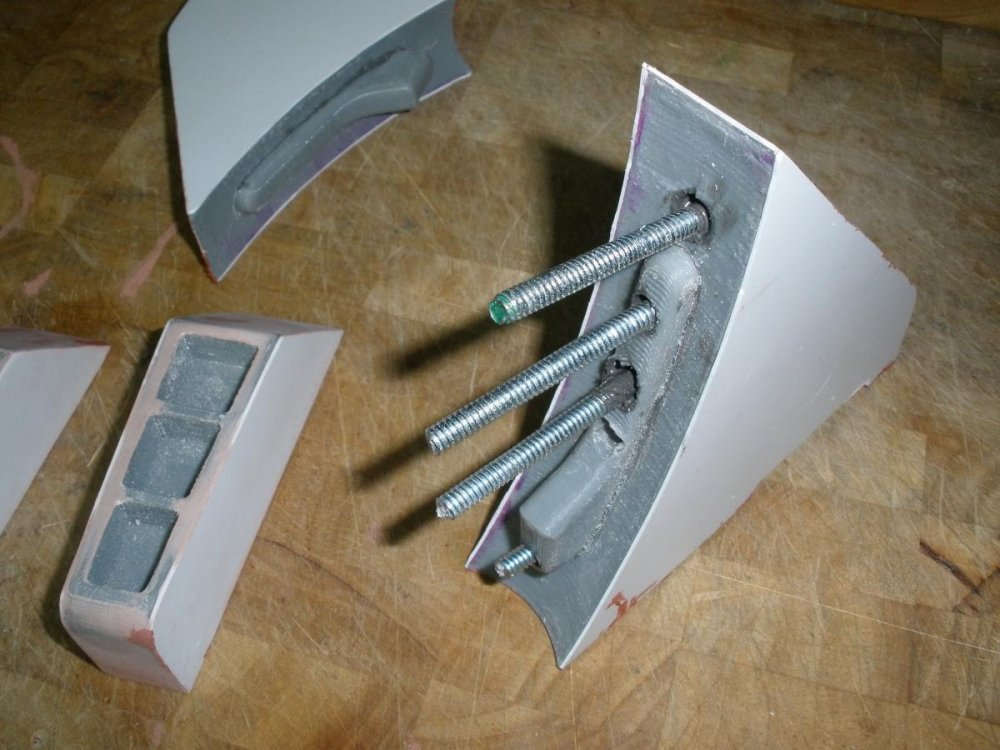

This post brought to you by Smooth-On XTC-3D....LOL. After 3 coats of epoxy and a lot of sanding The fins got a layer of sheet styrene and bondo. the bottom fin got mod'ed with all-thread rod, cut to length and JB-weld in. Along with a small filler for the rear cone so i can bolt and epoxy the fin on. The mating surfaces between the pieces were not as large as I was hoping for. And I didn't want to rely on just the shear strength of epoxy.

-

I have a cavity in the rear half. Just going to wire up 2 or 3 red LEDs and mount them inside.

-

So i think i came up with a way to mount the sling and not have it look like complete crap. Key-mod QD sling swivels.... Front fling mount. Made an aluminum plate that fit in the recess for my original idea. Drilled and tapped it to fit the sling mount. And then embedded it into the recess with JB-weld The lower fin got the same thing.. glued up a block of aluminum out of strips, drilled it up, and JB-welded it into a pocket I hollowed out in the leading edge of the fin. . the fin got back filled partially with resin for more strength.

-

Dam, thats dead sexy!! What kit is that? I think i need to add it to my waiting to build pile.

-

Solid, I got slow cure resin.

-

More glue ups. Body and Muzzle cap assemblies. I love the smell of Bondo in the morning...... Smells like.... Prop making. Bondo'd up the sensor/ fwd light thing. Needs a lot of priming and sanding to get it ready for molding. I'm gonna cast it in a transparent red resin. Started to bondo up the pistol grip.

-

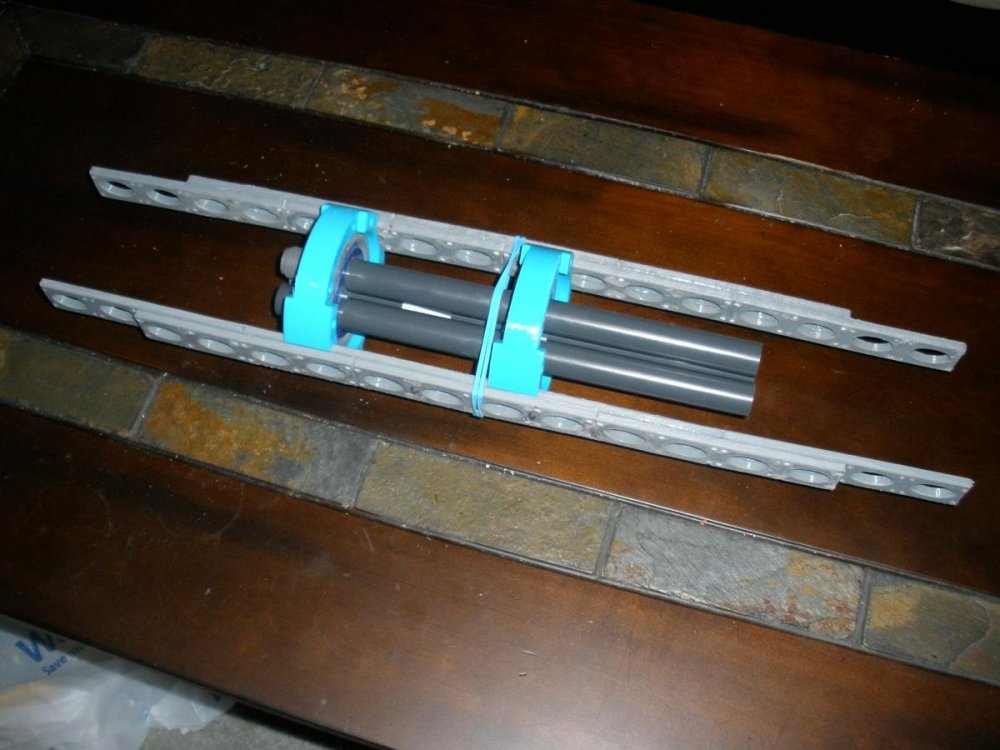

Little update. Been a little lazy over the holidays. but got some more stuff done. I have been printing out some of the internals. There is going to be a set of parallel rails running the length of the forward body. they are going to be both to add some strength and to provide something to find all the layers together. There will be a 3rd running at the top but thats just going to be a strip of extruded aluminum. The turquoise rings are going to be the chassis the barrels and guts will mount in. And then hopefully slide inside the body along the rails as a self contained unit. The rails took forever to build up. 24 segments that i printed out on at a time so i could use up all my partial rolls of filament. Then another couple weeks to glue it all up and trim it.

-

Not sure. most of it isn't glued up yet. Cant exact pick it up and weigh it right now.

-

No it's not gonna be airsoft. just lights and sound. Robo 3D R1