-

Posts

4650 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

I...errr...my children so want that 3D printer for Christmas! That is a cool idea. I'm going to look at Tinkerplay too. Most 3D software has such a steep learning curve it's annoying. - MT

-

That's cool looking! Thaks for sharing. I think it would look better with the TV SDF-1 and Daedalus, but I'm slightly biased - MT

-

That's cool! Are you using epoxy paste with filler to save weight and mass, or just straight epoxy resin? - MT

-

The muscle wire actually doesn't get that hot, but yeah, I could see in the photo the actuator is too big. Cool all the same! - MT

-

Man! Where was this stuff decades ago! Some REALLY cool stuff!!! Thanks for sharing the links. - MT

-

That thing is going to be huge! - MT

-

That's cool! -MT

-

I didn't know they had styrene nozzles, but that would TOTALLY be the way to go! ABS doesn't like to be sanded (that's why wmkjr mentioned the solvent bath). But styrene sands great while gluing and painting it is easier too! Then again,a good pattern will add surface detail for realism. - MT

-

Yeah, pictures! With all this robotic stuff, is it going to walk and grab drinks out of the fridge for you? Or at least shoot the cans off the table? I know - "wise guy!" - MT

-

I think I have most of the Southern Cross Armor, but no mecha. A couple fo those SC flyers are framed on my wall. That crab looks cool! Get me some butter! The fiber is coming along great Arbit. Just like the doctors say, more fiber is better! And Derex is in the lead for most prolific Macross World Modeller of 2016 (even though most of it has been Star Wars - we still accept you man)! - MT

-

Second me in! Even that "little" Daedalus is huge! That area circled is where a crane is supposed to come out of. I got all the translations back a few years ago. The bridge has a crane with cable spools under it, there is supposed to be cargo doors on the side that open, and then a crane supposedly slide out of the side, but it is never seen in the anime or drawn in books. - MT

-

Isn't that a photo of the new Enterprise set up top? I'm in the same boat. I've been drawing 2D for years and it's time to move from sculpting by hand to going digital. Mistakes are cheaper and scaling is easier too! It's time to get with the 90's...I mean 2000's!- MT

-

They don't look bad except for those "non-cannon" kits - MT

-

Those military trucks look great to include the "bullet loader." They remind me of the HO scale military models with a few N gauge thrown in. - MT

-

Experten 1/72 VF-5000G Star Mirage transformation kit

MechTech replied to Jefuemon's topic in Model kits

These look cool! 14,000lbs for a valk!? They must be styrofoam and an engine! I know - over technology. - MT -

Thanks Antibiotictab for keeping us in the loop! - MT

-

Woo Hoo! NEW stuff! - MT

-

That's cool!- MT

-

I may be biased, but it looks good! - MT

-

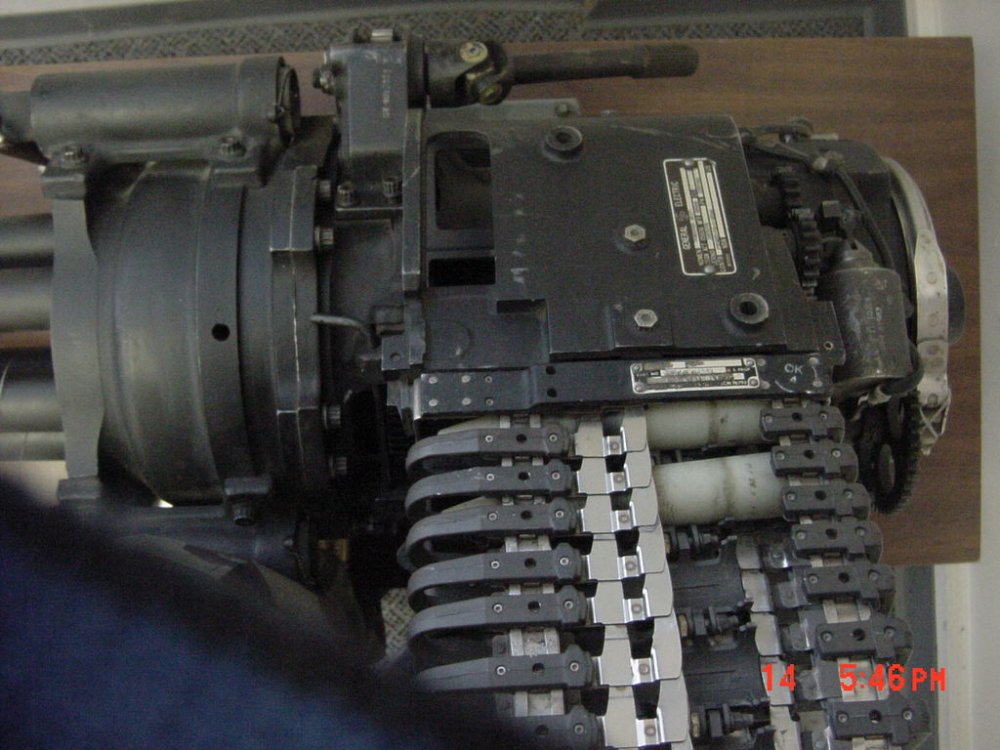

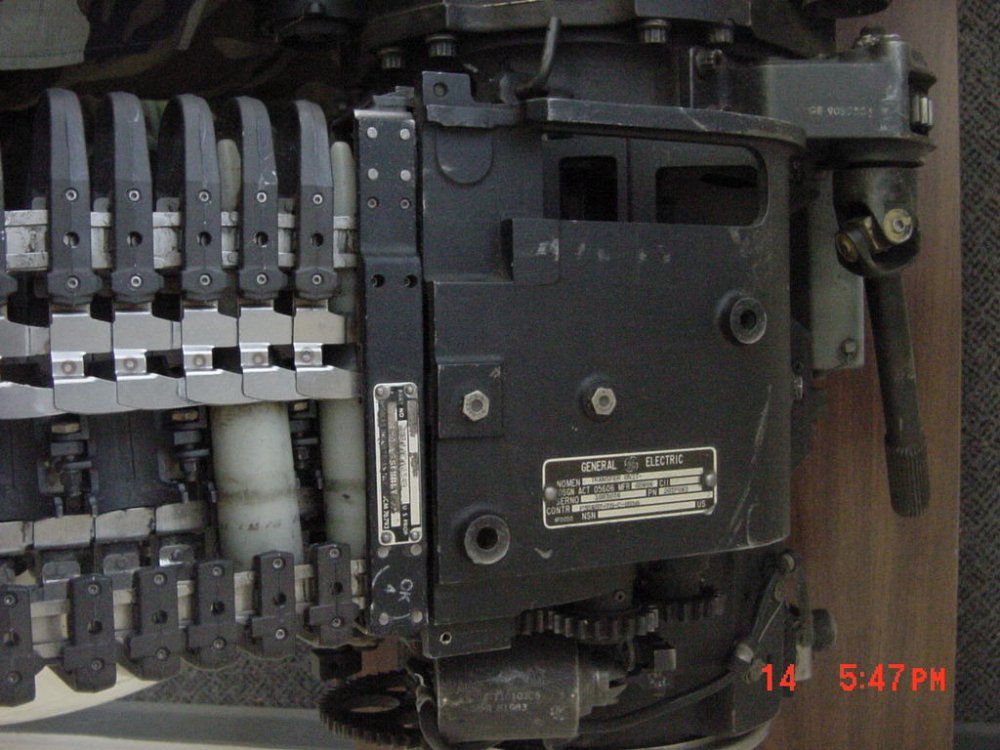

Those M61-A1 barrels and ammo look awesome! I got to get some just because they look so cool - and then make it somehow work with my bitty 1/350th scale stuff (even the 1/72nd scale version) I don't think those barrels are hollow to see light through; are they? If you need close-ups, we have an M61-A1 at the museum that is stripped of the drives and feed mechanisms. We have to somehow move it too! If you're interested, a trick to keeping the styrene from mucking up your bit is to let it breath and cool. I cut a bit, back off and then cut again. Lower RPMs and sharp bits help too. Even when I'm cutting on the mill, same thing. It's not fool proof but actually saves time trying to cut globs off your bits. And yeah, the chuck IS a cutting bit! I hate that! The attached photos are from our EOD guys taken a few years ago. This was a retired training cannon with simulated closed loop feed as if the drum magazine was in the loop. - MT

-

Those M61-A1 barrels and ammo look awesome! I got to get some just because they look so cool - and then make it somehow work with my bitty 1/350th scale stuff I don't think those barrels are hollow to see light through; are they? If you need close-ups, we have an M61-A1 at the museum that is stripped of the drives and feed mechanisms. We have to somehow move it too! If you're interested, a trick to keeping the styrene from mucking up your bit is to let it breath and cool. I cut a bit, back off and then cut again. Lower RPMs and sharp bits help too. Even when I'm cutting on the mill, same thing. It's not fool proof but actually saves time trying to cut globs off your bits. And yeah, the chuck IS a cutting bit! I hate that! The attached photos are from our EOD guys taken a few years ago. This was a retired training cannon with simulated closed loop feed as if the drum magazine was in the loop. - MT

-

It DOES sound cool! I bet it's like $400 and hopefully detailed thoroughly. - MT

- 1065 replies

-

- max factory

- dyrl

-

(and 1 more)

Tagged with:

-

LOTS of cool stuff guys! I'm stuck doing essays and almost finiished the Sea Dart. Photos to come soon. - MT

-

Glad I could help! Make sure your wife knows I'm in the U.S. and too far away for her to beat me up! By the way, I have bought from them a couple of times and everything was great. The 6mm diameter motors are awesome for models. They may be a little noisy because they drop down high RPM to lower. You can do two things if you care about the noise. 1) Drop the voltage down. 2) Mount the pieces in rubber housings to isolate them. The plastic conducts the noise. The brass metal housed motors are more quiet. Overall, they are torquey! Here's the 6-7mm diameter micro motors (in case you drop your cell phone) I used several on the Daedalus build and still have a couple. - MT

-

That thing is HUGE!!! The earlier pictures make it look large,. but not like almost a meter! Looking great so far! Are you gonna vacuform the bridge? - MT