-

Posts

4650 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

That's looking cool Kelsain! Yeah Arbit, it does just grow and grow! Like from an X-acto to a file set, to an airbrush...to a desktop mill! Sanity is Optional, after a lot of research and experience, Sherline has the best small hobby machines by far - no comparison! I have gotten some of the cheap Chinese machines and they have a lot of play in them or don't work smoothly. I even bought a higher end Chinese mill from Micro Mark, and it has issues to include a control board that is starting to go. The tables have a lot of play in them making them wobble. Even after a lot of cleaning up and re-machining, the tables still don't run true. I'll be buying a Sherline mill when I get the money. My Sherline lathe is awesome and runs smooth as silk and is very quiet. I can lathe at night and no one gets woken up. You can even take the head and use it on the lathe or mill to save money, but I'd like both to make it easy to go between machines. Sherline is right in California between LA and San Diego too. You can visit them to check out and try their machines. http://sherline.com/ Everyone: At the bottom of their page is "The Joe Martin Foundation for Exceptional Craftsmanship." Get a box of Kleenex to wipe up your drool and click on their museum link. Scroll down and check out some of the machining examples. The best part, styrene machines like butter versus steel or aluminum. My cutting bits stay sharp for years on styrene only. - MT

-

That's cool! I have to agree with the color choice. Russian research says it is "calming." I think it's nauseating, but it fits the Zentreadi to a "T." - MT

-

Thank you very much guys! I started getting into machining because it is ultimately just making a jig. For instance, cutting a bunch of styrene strip to the same length you use a tool or make a jig to keep the parts the same. Machining does the same thing for me on a more flexible level. Even some of the tools you saw me make are a form of jig to help me make something like the barrel. Arbit, It started with a drill press. Sure you can drill holes with it, but if you put parts in it like styrene you can spin them and machine them a little by hand such as making missiles. Its like a lathe, only vertical! Then I got a small X-Y table for my drill press and that makes it like a mill. Now I could make precision cuts in marked increments (like a jig again). Add a rotary table to the X-Y table and you can spin parts and cut them like making gears or simply cutting a circle out. I got tired of calking my neck to the side so I just got the machinist lathe. They say you can make almost anything on a lathe and a mill and I have to agree. Attached are some photos from the 1/350 Monster build I did about three years ago. The first photo is of a mill with a rotary table and the work is supported by a tailstock to keep it stiff. The second photo is another piece on a rotary table with notched cuts being made into it for a ratchet. It was then cut off. Both parts are in the last photo. The ratchet parts are the top right and the "arm" is of course on the bottom. Machines help me make true cuts where as all hand methods were far less precise and clean. If you keep serious about model making, especially scratch building, machines may be the way to go (or 3D printing). By the way, the aluminum part of the barrel I machined, the brass was from an aftermarket 1/32 machine gun barrel. It's about the same diameter as regular pencil lead, so it is very thin! More photos coming up as the parts dry. - MT

-

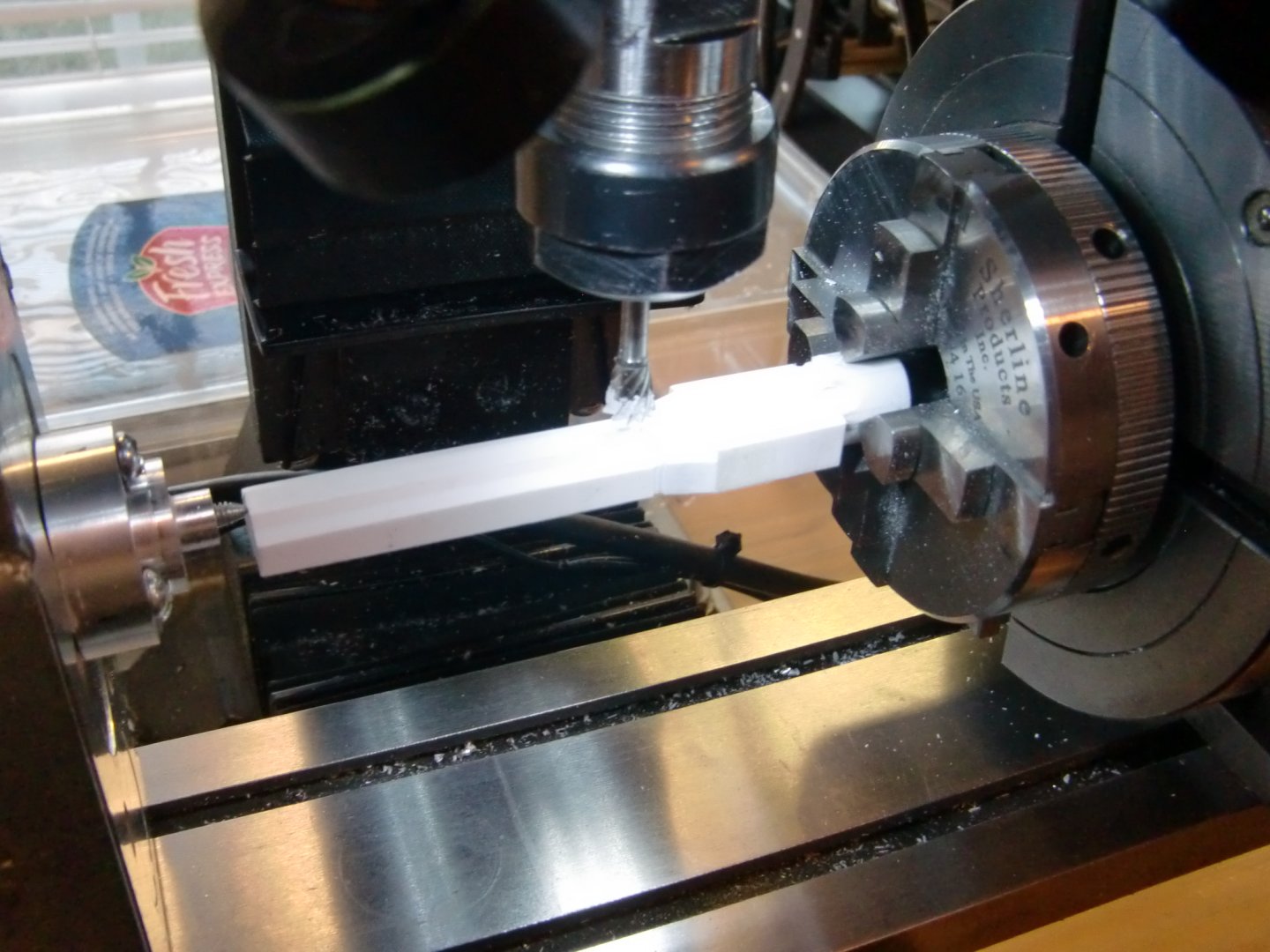

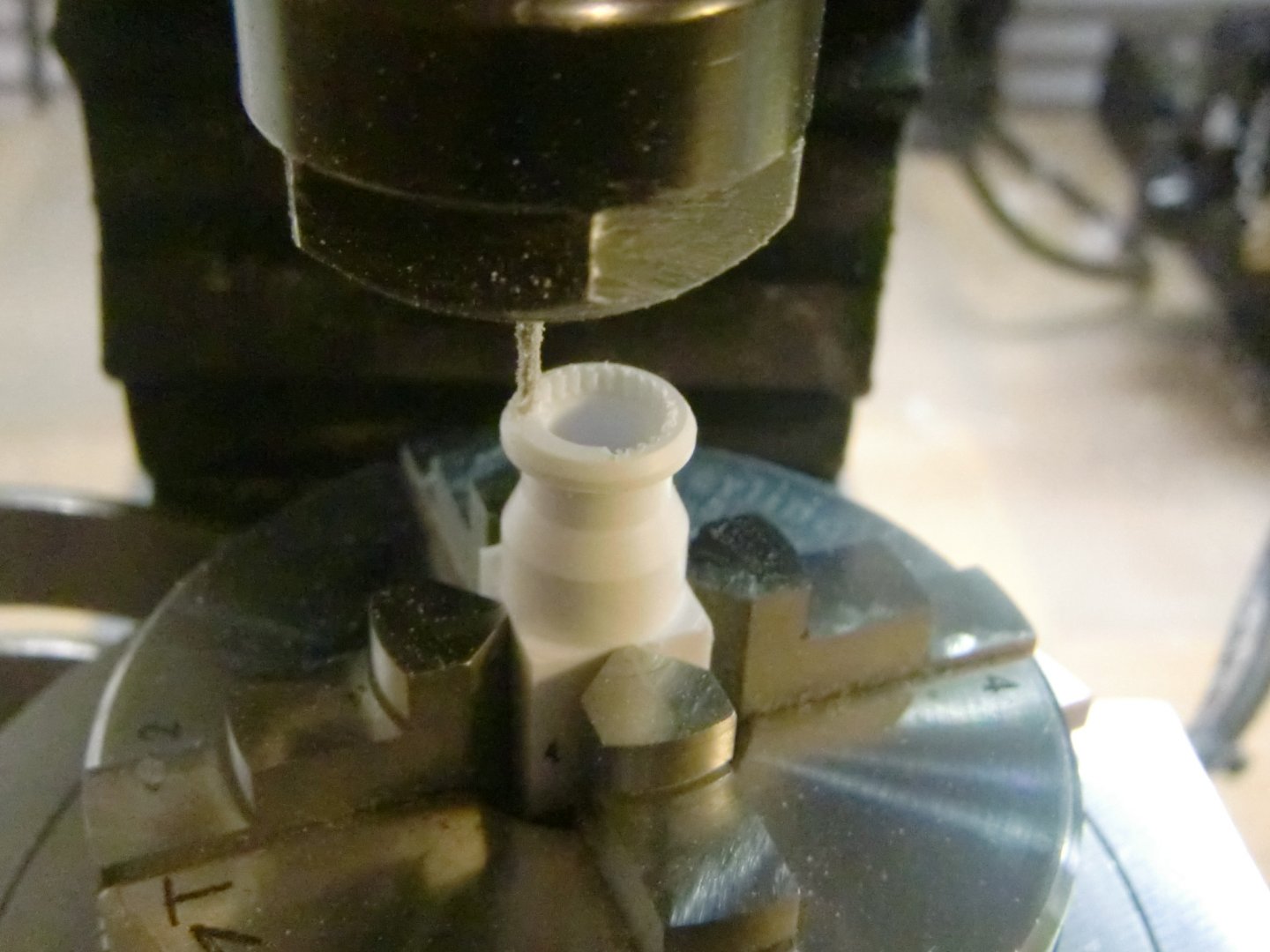

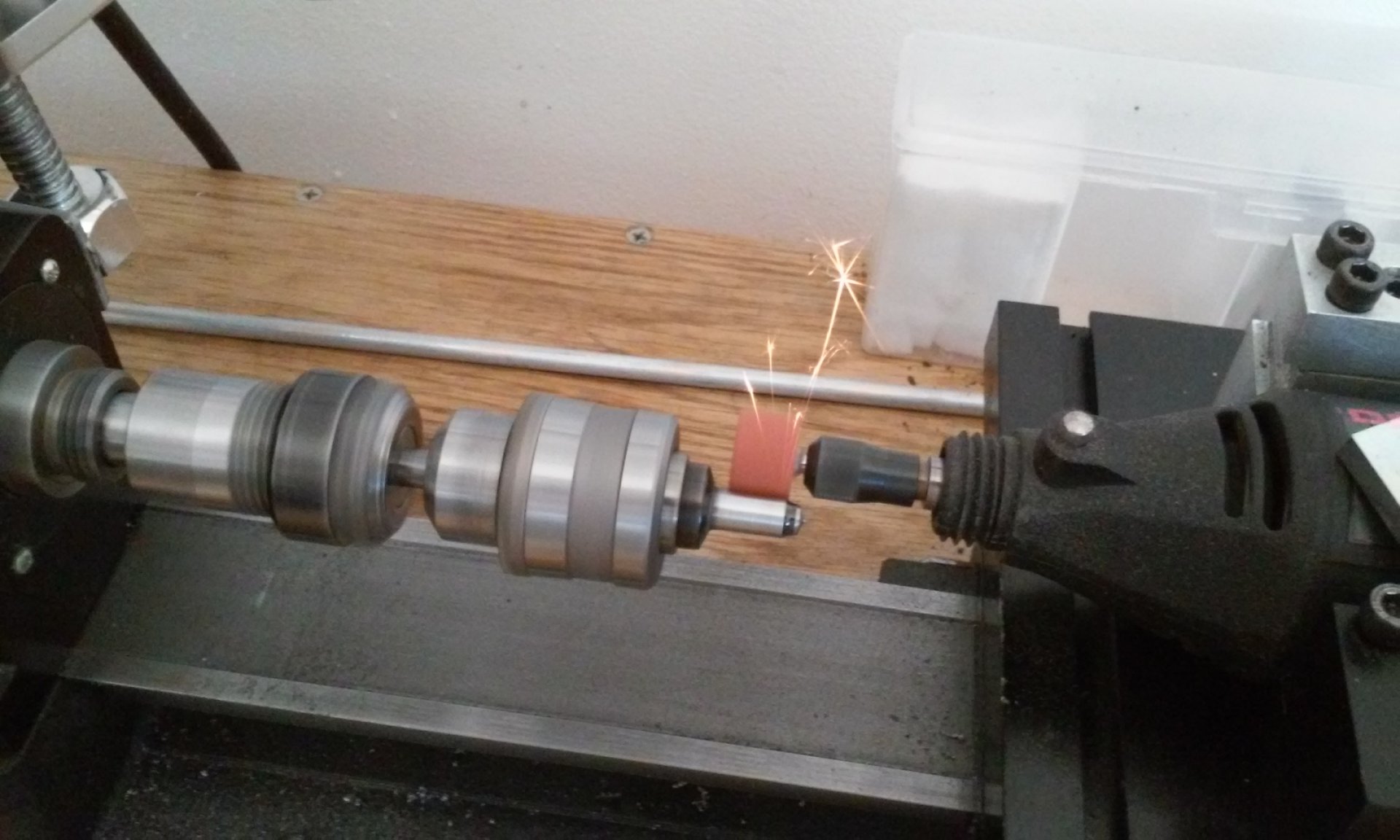

I saw those colors and said "Matchbox!" Hopefully the fit isn't too bad on that kit. Some of Matchbox's colored moldings were great when I was a kid, and then others were a pain because they ddin't match the color scheme. Things have been slow going back on my ship. I create one thing and then somehow screw it up. I need to lathe small gun barrels for models so I mounted a drill chuck into bearings for the lathe tail stock. Now thin work can be supported without warping easily. I have to remake this tool too because it has some wobble in it. Got a nice action shot of sparks flying. Then I machined the gun barrel (Oto Melara 76mm) in 1/72nd scale. The turret mount was machined from solid glued together styrene blocks and the rest was from styrene sheet. They were done on a rotary table on a mill. That tool has made a lot of cool things possible. Need to take more pictures after the glue sets and they are mounted to the turret.- MT

-

I just realized the GU-11 gunpod is the same scale (and roughly) the same size as the old kit: http://www.macrossworld.com/macross/models/imai/imai_orig.htm I have that kit. So yes, you can make that sucker Airsoft capable! Hmm, that would be cool. Those fast packs are large! - MT

- 1065 replies

-

- max factory

- dyrl

-

(and 1 more)

Tagged with:

-

That's coming along great! - MT

-

Those are some great improvements! Are you going to be offering these up? - MT

-

That would be cool with some custom decals like pilots helmets have on them. - MT

-

That looks cool! What software are you using? - MT

-

They came out great to include all the articulation! - MT

-

Thanks Arbit! Yep, it was so noisy the engine sound blocks out most of the PA system sound in the video when it flies nearby. That looks good so far Zombie! I have the 1/350th Yamato and the Tigers are my favorite. They just look like they could actually fly. The other craft look too small to even fit pilots in. I was hoping to have a machined gun barrel for my ship model, but had some issues with the thin material bending. Trying another way. - MT

-

Looks like they may have the missiles visible for the top fast packs. If not, they are in pieces to scratch build them. I'm hoping this is not too much! - MT

- 1065 replies

-

- max factory

- dyrl

-

(and 1 more)

Tagged with:

-

The airshow was great! Most of the people I was with were Navy/exNavy. We all agreed the F-22 Raptor put on the best show by far. What else can flip head-over heels and then go Mach 2? It was so humid that you could see the transonic shock cone forming over it on the high speed pass. It was also the loudest hands down! That looks great Pegbuzz! I never saw ROM, but your details help make him convincing. - MT

-

Great stuff guys all the way around. I've been missing out! I was busy prepping for the Andrews Airshow for two weeks prior and recovering last week! It was worth it though! https://www.facebook.com/paxmuseum/ So the problem I've been having is machining things on the mill and I can't cut parts off cleanly. Dremel bits are too flimsy and don't cut straight. So I realized I need a jeweler's slitting saw. But the Sherline arbor is $50 before you buy the blades and it is too short! So I machined a $2.50 bolt (actually 2 because I blew the first try) and made one today. It is tapered to fit into the mill where a draw bolt holds it in place. Now I can cut slits in brass to make props and cut model parts more accurately. The blade is as thin as Xacto's thin razor saws. Next step is to finish the boat and the Nausicaa's Gunship. - MT

-

That's cool! What scale is it in? - MT

- 2 replies

-

- neutron s missile

- mospeada

-

(and 2 more)

Tagged with:

-

That came out great! A great build and finish. I can't tell you how many times I have had to mix custom paint for Macross models. That's my only beef with them, all those crazy colors. - MT

-

That is cool! They are so TINY! - MT

-

Great job putting papercraft and bluetooth together! I would have never thought of that. It came out great too! - MT

-

Superglue on paper is great! You can do the same thing with fiberglass too for lightweight applications. I'm redoing some thing on the gunship. More as I get more done. - MT

-

Lots of cool stuff guys! - MT

-

This is looking really good! You are right, there are fewer model posts all the way around. Even the most popular "What's on your workbench" thread is getting less traffic. - MT

-

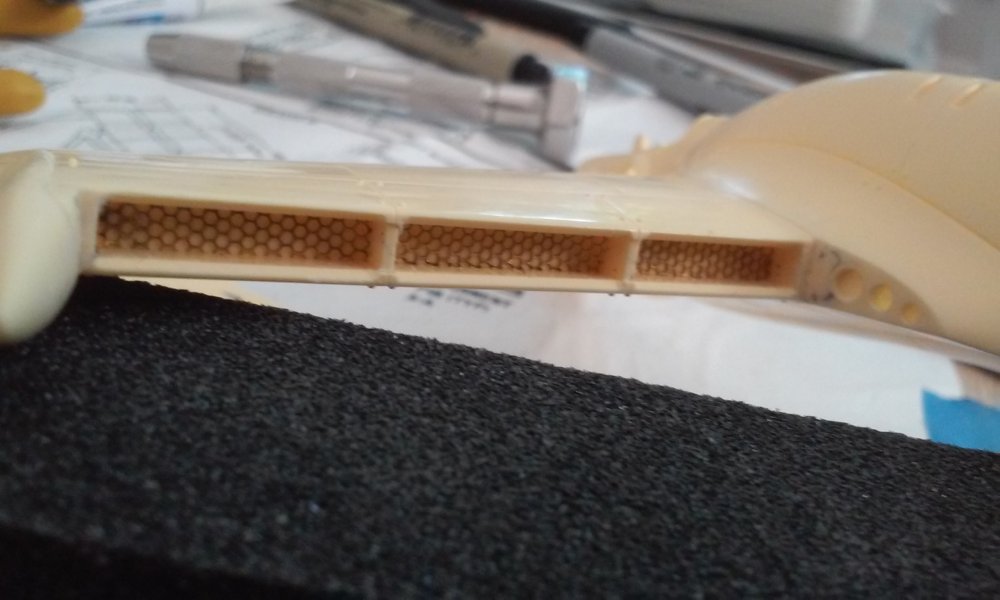

Okay, I'm now working on the Gunship. The flap/exhaust system is cool so I filled in and got rid of the stock hinges which put the flaps right in the way of the exhaust. I made new hinges in them out of piano wire and drilled micro holes. The piano wire actually sits in a slot carved in the flaps which makes them stronger and hides them. I added PE polycelled pattern into the exhaust area then painted it flat black. The hinges will all be hooked up to cranks inside and connected together so they can open and close together. They move in opposite directions in a small space making the engineering fun. - MT

-

It is definitely a must have (that's why I have one and its not in my scale). The molding is crisp and the detail is good. Its an easy weekend build or two.- MT

-

I painted my shop bright white! Then I have a closet that juts out in the corner. I put two of these Shop Lights on top facing outward. I bought mine at ACE hardware on sale. I now have bright diffused light. I then bought two more and put them over my work bench - I rarely use them! The two are great and burn white. NO MORE CFLs if I can help it. They mostly burn yellow. The LEDs also don't emit anywhere as much ultraviolet light either. Just DONT LOOK DIRECTLY INTO THEM! The red LED element is close to laser light. LED lights are TOTALLY worth the money. Your electricity bill goes down too! Did you guys see this gunship mod? I'm tempted! - MT http://egloos.zum.com/lakumimi/v/1516946