-

Posts

4305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by wm cheng

-

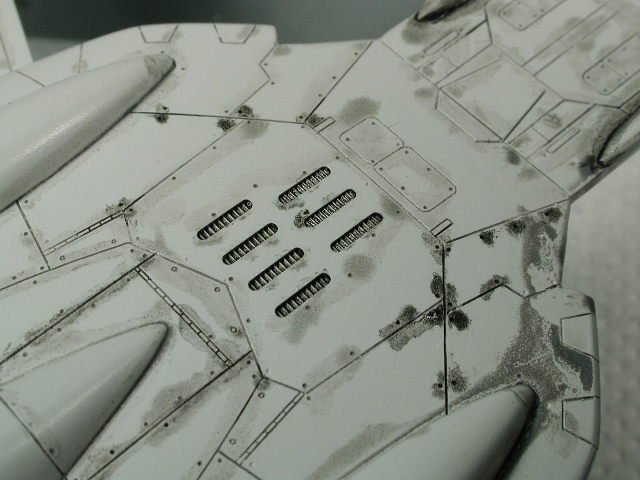

Here's an overall shot, I tried to trace the panel lines with my airbrush (or as close as I can to them). I used a thinned down sky grey for the post-shading. I thin it down 70:30 thinner:paint ratio, much more diluted than I am used to painting with - so it flows easily out of the airbrush and prevents clogging. I really need control for this stage and I try to get the finest lines I can. I often go over lines quite a few time because so little paint comes out - this way I can: A) see where the paint is going to make sure I hit the lines B) vary the darkness of the shading C) after a few strokes I can get an more steady and even stroke D) because I chicken$h@! so I like to build up my colour in multiple passes I hold the airbrush quite close, maybe 1-2" from the model to get a fine line. Periodically spray full open onto a piece a paper to clear out the airbrush and prevent splatter - then go back to the model. This is much heavier post shading than I usually do, but hey I think this bird is more weathered than most - finally not a new demostration scheme (MacrossPlus birds) and I noticed a lot more weathering on the CGI shots. Plus when I apply the stark black stripes, that will make such a contrast to the eyes, that these post shading will fade into the background more. I don't want to over do it at this stage, I still want to do another pass after the decals are on to tie them into the paint scheme more - so treat this as 75% of the desired effect.

-

I focus on all areas, there are no real specifics, but I do omit the really small details that I know I can't get my airbrush in tight enough. Generally I try to hit all the contours of the aircraft - concentrating in the valleys with a darker colour, and hitting the highpoints with a flat white later on to simulate wearing. I think of it in terms of shading a drawing, where the painted color represents the mid-tones and any recesses gets shadowed with a darker shade and any highpoints gets hit with a lighter color. Also think what gets hit with the blast of airflow that should get a bit lighter worn, where as areas that are recesses tend to collect debris and dirt. Then after all is said and done, I sometimes just spray where ever I think might accentuate something (artistic licence )

-

I love being able to see some glint of metal inbetween the holes of the airbrake!! I also love those slotted vents on the back. I've sprayed another coat of semi-gloss clear coat (allowing overnight to dry without me picking it up ) to protect this stage in preparation for tomorrow's post shading. If I over do it tomorrow, I can always take a little windex and "erase" any extra post-shading to this point without disturbing the paint underneath.

-

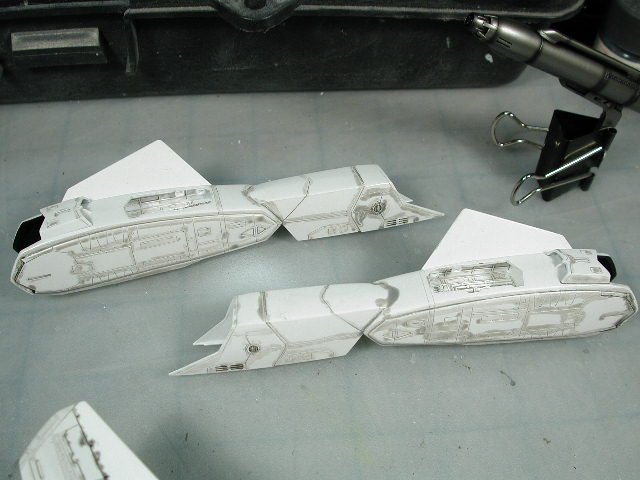

Just have to fit the legs on - too bad they don't slip on and stay on allowing them to be removed like the VF-1. You really need to leave gluing them on till the very end since you need to decal the "inner" calves before they get glued in.

-

Cool! you guys convinced me, I'll try to edge the doors in red when I get to it - any tips David? I was thinking I'd use my red sharpie marker again - it worked pretty well on the Yukikaze plane - and there's better control on it. Do modern Navy aircraft still have the red edges? Graham, I would like to have the VF-0B twin seater (buts that's not the same as building it ) I'm sure everyone here has the collection bug but I don't think there is enough time in our lifetime to complete all our kits (unless I won the lottery ). That being said, you're right, It would be nice to see them together with the off-grey scheme against Roy's whiter bumble bee scheme. You're also right that the fit of this kit is not as good as the VF-1 - it feels a little rushed, even some of the panel lines seems to run pass each other at intersections So I'm not too keen on all this work again (at least so soon) I want it, but it would probably be on the back burner as far as a que is concerned. I'm actually more interested in the VF-0D (is this the delta winged version of the double seater? - its seems to be grey/blue if I remember correctly). Well here's where we are tonight, I got the panel lines down to a respectable subtlety - I always have it dark when I first start (I love the details) but always end up rubbing a lot off or lightening them - because they are just too obvious. I think this is a good comprimise - it might be still a bit strong, but with the high-contrast black stripes it should be ok, I can always lay a wash of white oil paint in there afterwards if its still too dark.

-

I use low odour varsol - this stuff doesn't stink and it seems less strong, but yes sometimes when its too thin, the paint pegments have a tendency to separate into fine particles in the thinned solution - its a problem. I think enamel washes don't have this problem, but I'm chicken, I'm afraid the enamel washes might eat away at the acrylic undercoat since enamel solvents are usually harsher. Ah... David you cought me, your right (wrong colour choice - artistic licence), but I like the idea of the brake opening and revealing some guts of the aircraft - it makes a better contrast to the white/grey - plus my other Valks (VF-1) have a metal airbrake compartment. What do you think about lining the landing gear doors with red? Too garish on a 1/72? or too old fashioned? I haven't really seen any references to the VF-0 - but I doubt that the landing gear door edges are red-lined. The crack is now nicely sanded down and awaits another coat of white then clear-coat - I'll do it after I wipe down the oil wash, I'll post some pictures soon.

-

Here's a close up, I don't know if you can see the different shades of wash - I try to do it while they are all wet, so that they will dilute each other and not create any harsh colour transitional changes.

-

The interior of the landing gears, I think they turned out ok, the pins aren't totally gone, but when they are mounted into the aircraft, I think they will all but dissappear.

-

-

Ahh, my favourite part... the oil wash, what a pleasure on such an amazingly detailed model. I must admit, I'm a real fan of hasegawa's interpretation of the lineart by adding all these panels and bolts, I find the new Macross Plus planes a bit scale-less (even if they are accurate). I tried to vary the washes a bit like my shading now. I use a light grey wash for all the overall panel lines, a black for any vent openings or moveable surfaces and a brown for any hydraulic leakeages. This is just the panel line pass - I will clean it all up and do a separate weathing streaking pass later on (finally now is the fun part!!)

-

-

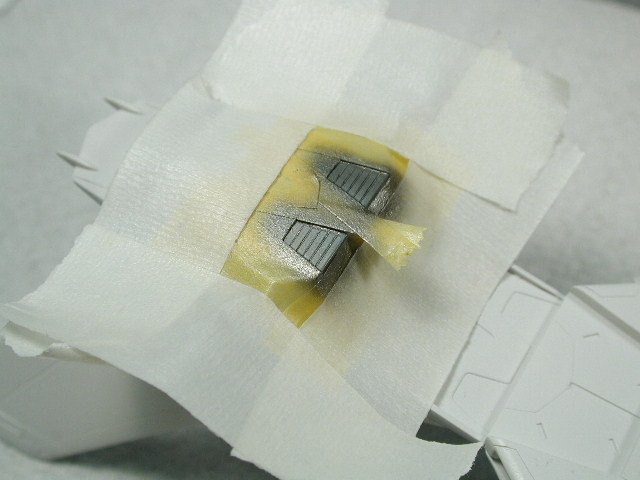

The masking removed - I try to remove it as soon as possible, just to minimize the possibility that some tape residue might remain behind. Noticed that I didn't even paint or glue the three thrusters in there, on a dry fit, I noticed that they will not be seen at all, the arms and legs completely hides this whole area. Thank god, I don't know how to paint that builkhead anyways, you couldn't paint it afterwards and place it in (like the grill in the rear) - it had to be glued in place when the backpack was glued to the fuselage, so painting this bulkhead in place afterwards insitu would be a bitch!

-

The top parts masked and sprayed. I should of painted the interior intakes on the top chest pieces black first before gluing it into the fuselage, its hard to get the airbrush and paint into such a deep crevass. I had no problem with the YF-19 or the VF-1, but this model is deeper.

-

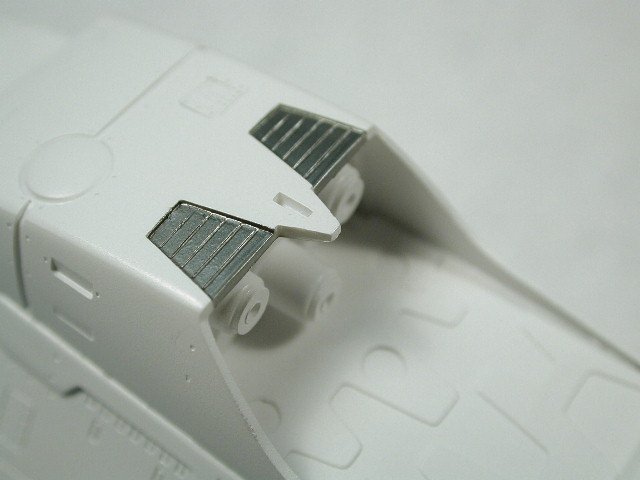

Again, I am using this Alclad steel metalizer stuff - the tape protects the light grey/white on the exterior. Doing it in this order, exterior paint first, then interior metallics will bring the steel colour up to the light grey creating the illusion that the metal is thinner.

-

-

AARRGHH! Wha, what happened, it looks like the clear-coat shrank and peeled away from the gloss white undercoat leaving this crack I don't know exactly what happened, I'd guess I laid the clear-coat on too thick and maybe the undercoat wasn't completely dried yet? Man I hate it when this happens, I am going to try to very gently sand the clear coat down with 2000 grit sanding film (I hope the crack doesn't extend down to the plastic) to eliminate the crack and will have to put the white gloss over it again and a careful light clear coat.

-

Here's the intake vanes, I've tried to bend the ends up slightly, and I am going to glue them in at a slight downward angle like the F-14 excess bleed ramps in the intakes, plus it will partially obscure the fans and the interior of the intakes. The back of the knees are shaded now, but you really don't see much of them once the legs are glued in place. I've given the entire thing a coat of ModelMaster Clear-coat of semi-gloss mixed with gloss finish to seal in the paint so far (letting it dry overnight), so I can do an oil wash tomorrow and hopefully some post-shading.

-

-

Nice cans David I should wear gloves - those rubber latex should be fine, but I don't. I did get one small spot of slight finger prints (easy on really glossy surfaces - thats why I usually go semi-gloss) but luckily a coat of clear-coat eliminated that. I am doing a little burning on the feet/afterburner nozzles. I airbrush shade these with flat black, later to be sealed in with a clear coat of semi-gloss.

-

Hey thanks Solscud007! I just ordered one - I'll post to let you know how the service is when I recieve it. For those who are curious, it was $21usd in total shipped to Toronto Canada. A far cry from Toys Square here that has it for $60cdn!!

-

Very cool metallic red idea! Can't wait to see more, you did a great job at sanding away the seams - if I remember correctly, those old kits are a bitch.

-

Would you believe I used sissors up until 2 years ago!! I've got myself a pair of cheapies, which are fine. But I never cut that close to the actual object to care about how straight or sharp the blades are. I always cut as far away from the piece as I can, then with the piece separated, I carefully use a very sharp X-acto knife from the exterior side (good side) of the piece cut parallel to the surface leaving a bit of plastic behind. Then I sand down the sprue nub - I find that this way, by sanding excess down its easier than filling any nicks or chunks missing.

-

Great job so far - sorry to hear that the post shading didn't work out for you, I'll be interested in seeing how the pre-shading will be (I've never done it this way before). You might need a fair bit of the light colour to cover up all that black though. Don't go building too much, you were my "See darling... look how much they have compared to what they've built! - I just need a few more boxes..." The gun barrels look great!

-

Hey a tip, Don't do a black artist oil wash over anything painted with the silver chrome Tamiya Markers. I just did that to the intake fans, and the Varsol in the thinned down oil paints ate away at the Tamiya silver and I got a mucky mess. Luckily I cleaned it up and plan on sealing it first next time. Hey any takes on different glues - what about you David? Cool pic of that old SU-24 - you're right, you don't really realize its grey until you get a pure white next to it. Hey I didn't know the tailcones on the SR-71 are ceramic and are white, cool, lets see some pictures.

-

I just love the detail on these afterburners !! I hope you can still see them once the feet are on the legs - a black wash really brings out the effort Hasegawa puts into them. Ok, must leave the model to dry for the time being. I might assemble the landing gears to prep them for a spray of gloss white too. (in case you're wondering why I have time to work on this during the week - my film production went down and I got laid off again so its time to hunt for work again - at least I can devote more time to this baby and update more regularly)