-

Posts

2630 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by arbit

-

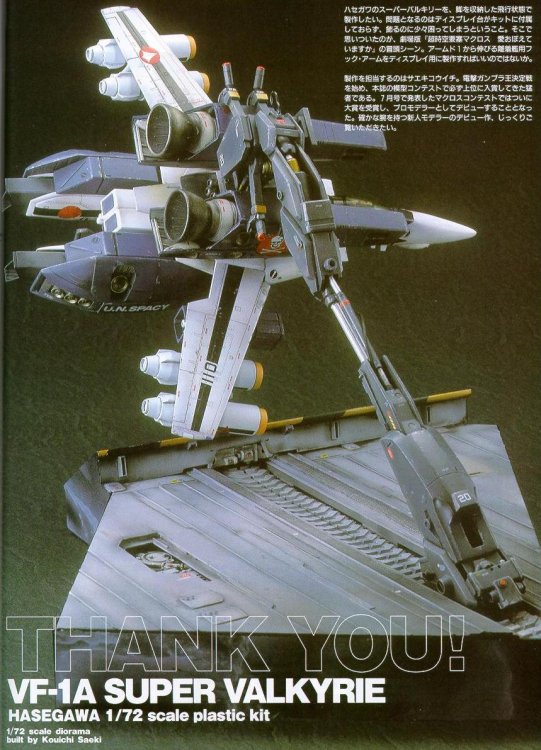

A lot of greeblies on the Arm are from the Hasegawa landing gears. The heavy base Arm is entirely bashed from the Bandai 1/72 Valk, which is great for spare parts, if for nothing else.

-

Your son likes it? In that case I am really proud of myself. How old is he? My oldest is 13 and he seems to like it too. Big DYRL and Macross II fan.

-

Your most recent Macross or toy purchase! General thread.

arbit replied to Gakken85's topic in Hall Of The Super Topics

Respect for both of you not losing your cool. Good people. -

Thanks, but I still need to put it all together. Actual credit goes to bonobeet, DorobouHige2008, WM Cheng's Step-By-Steps, Mechtech, NZEOD, and these guys.

-

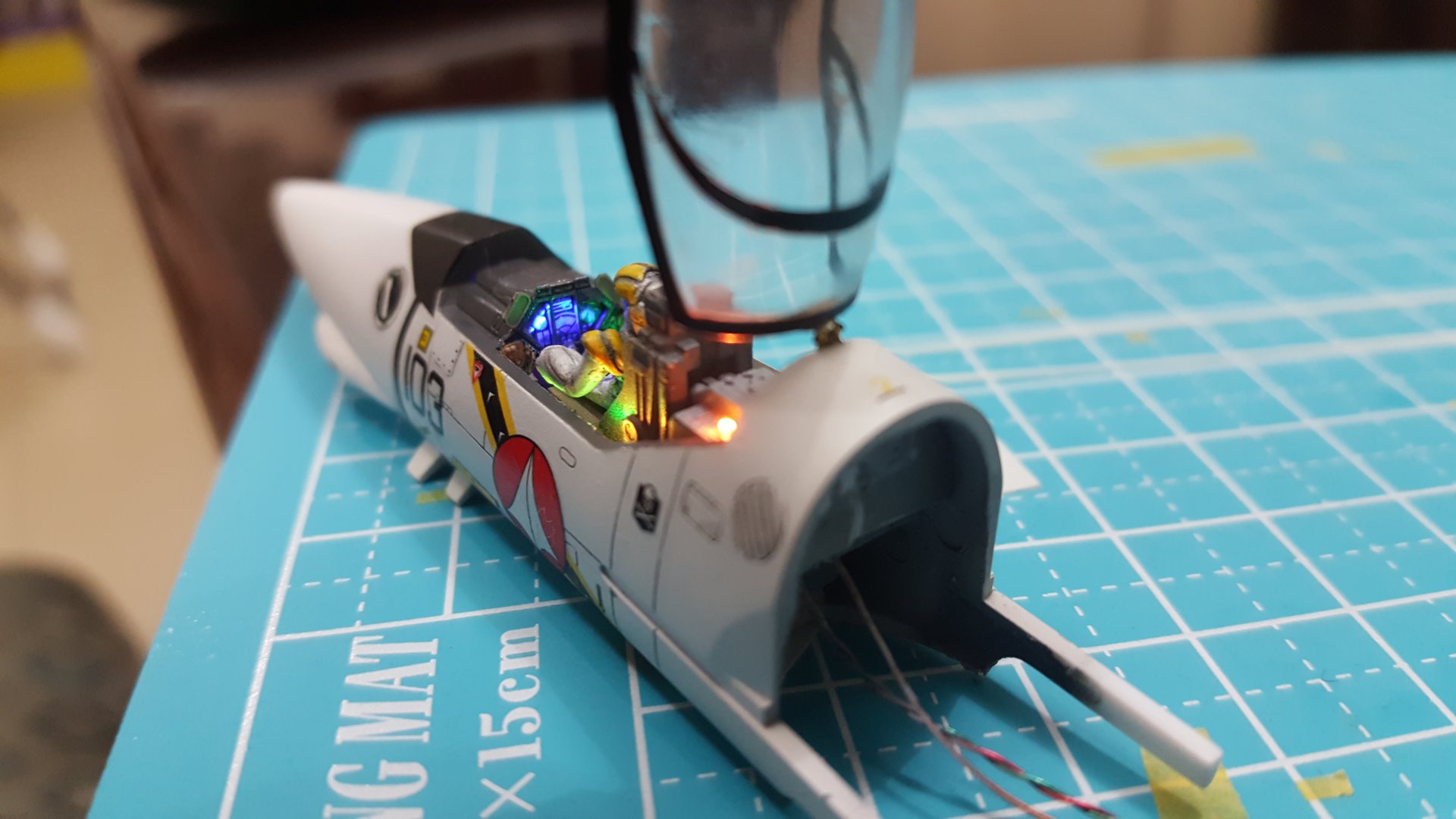

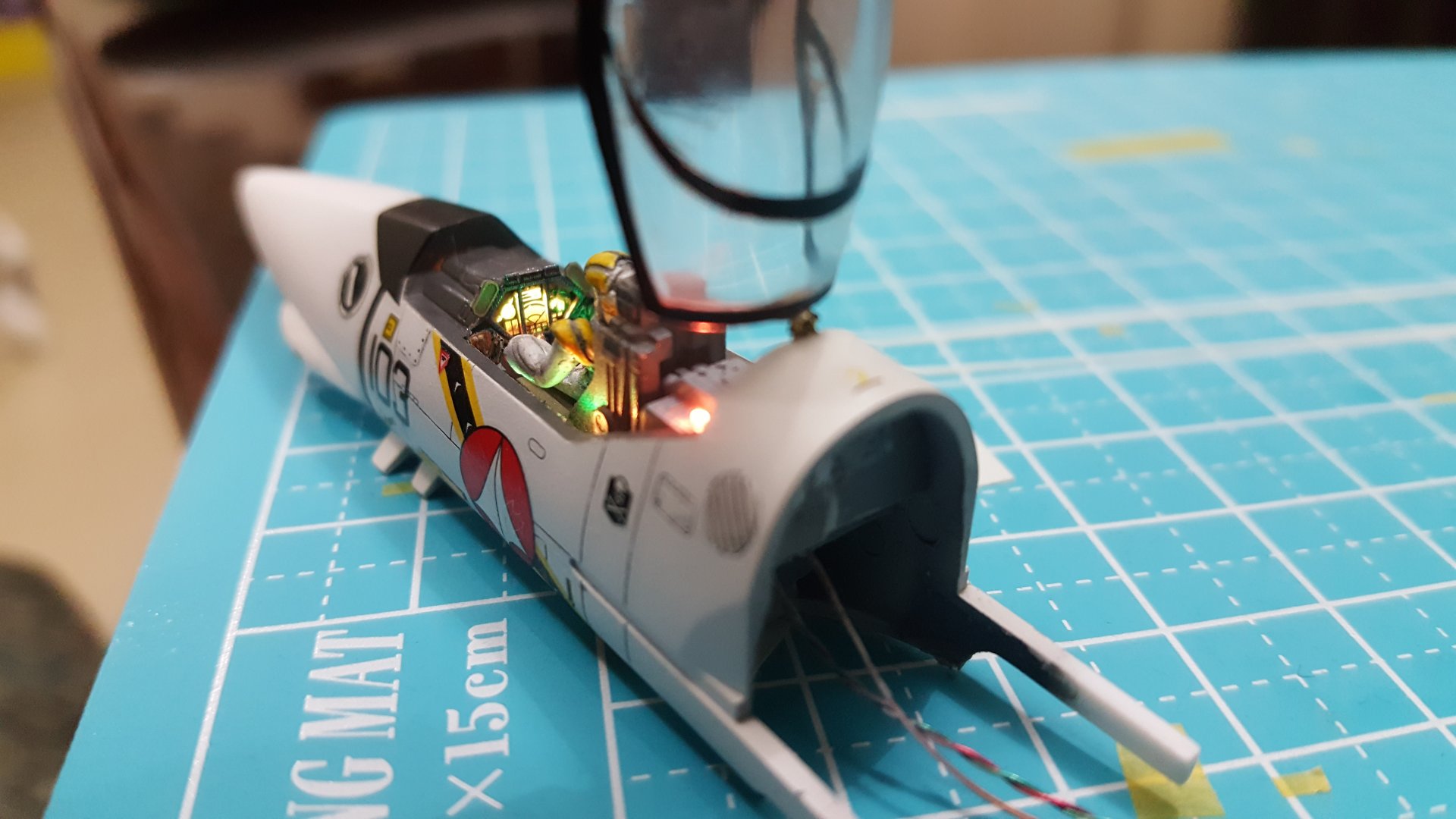

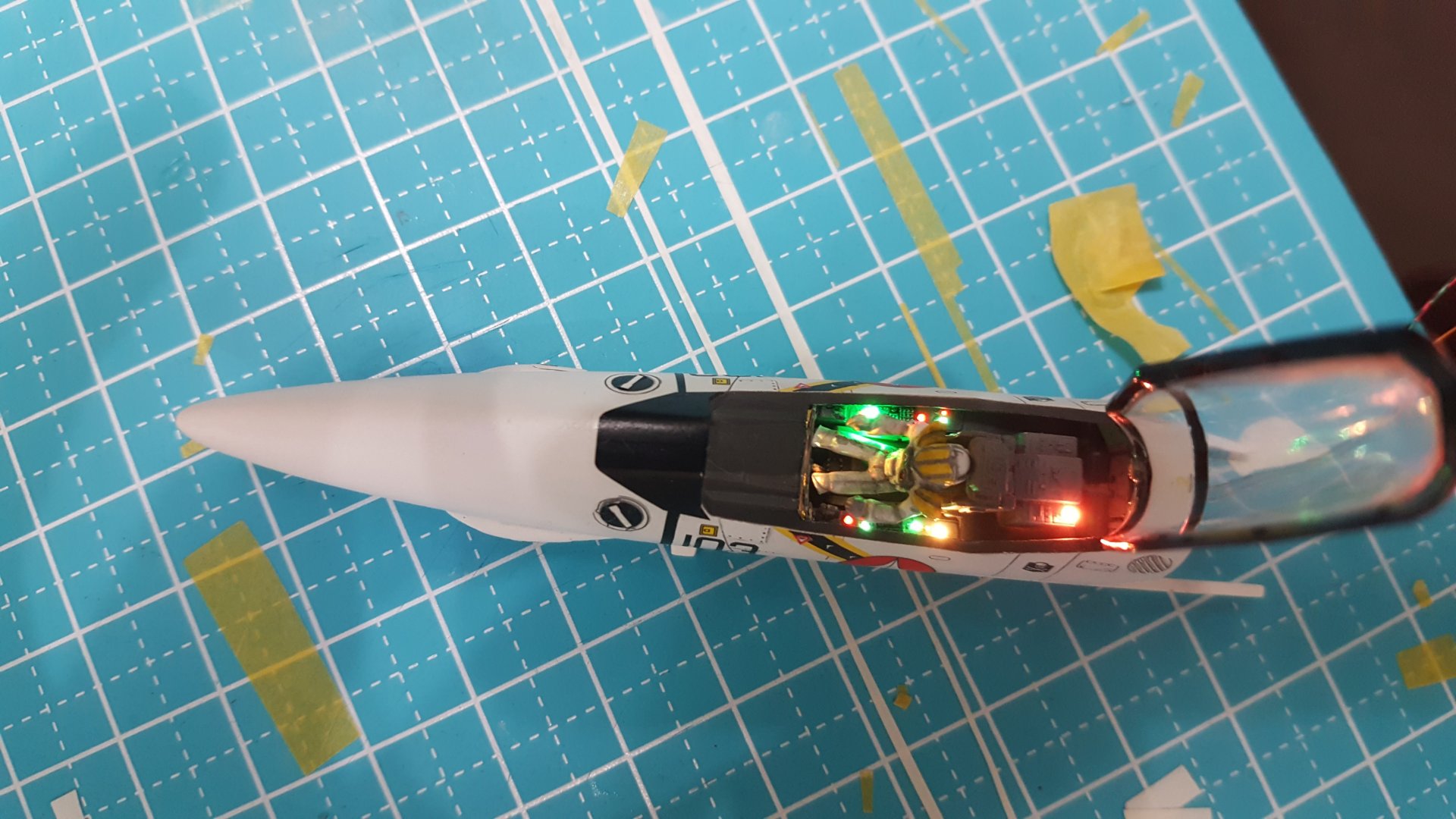

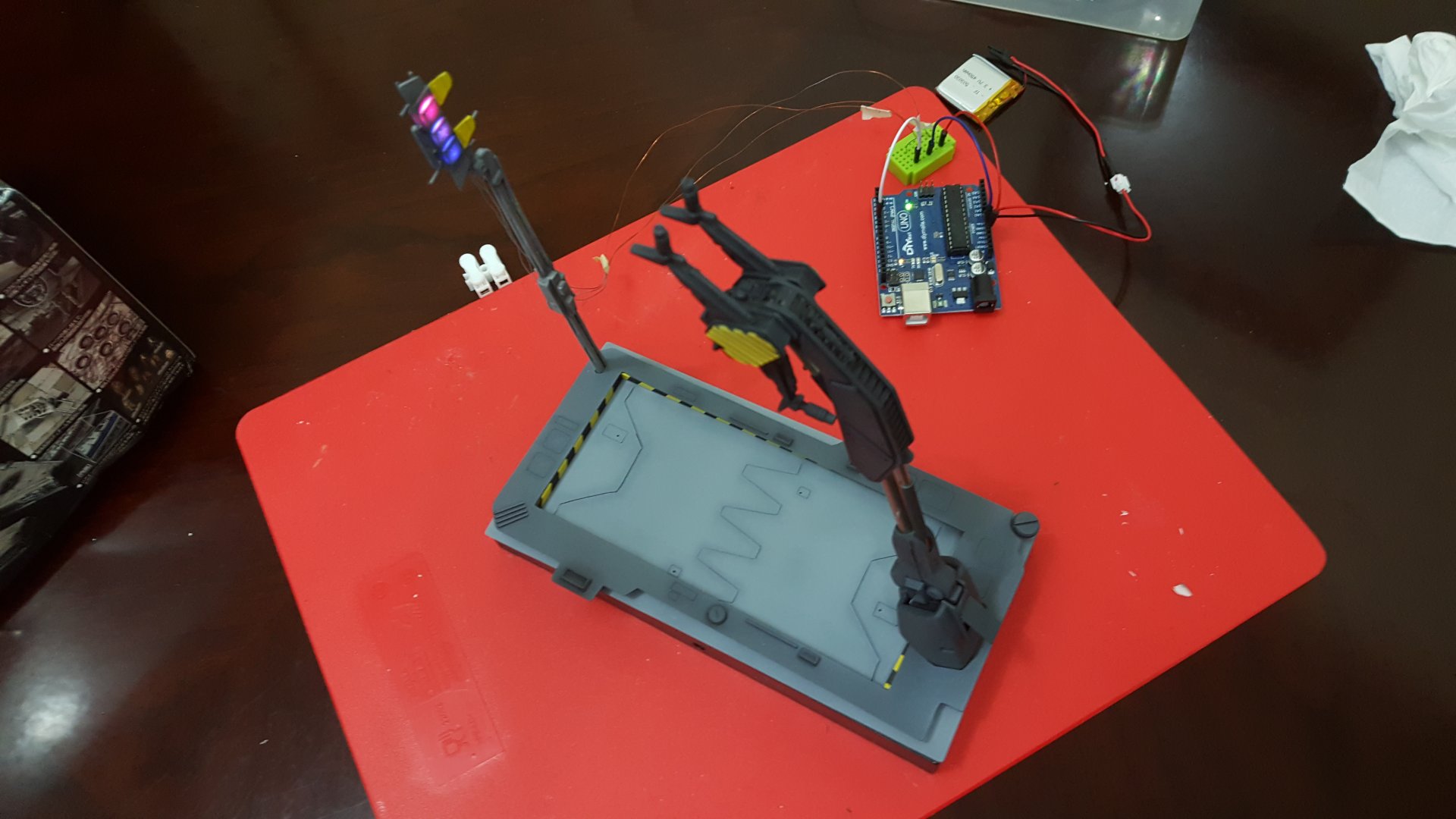

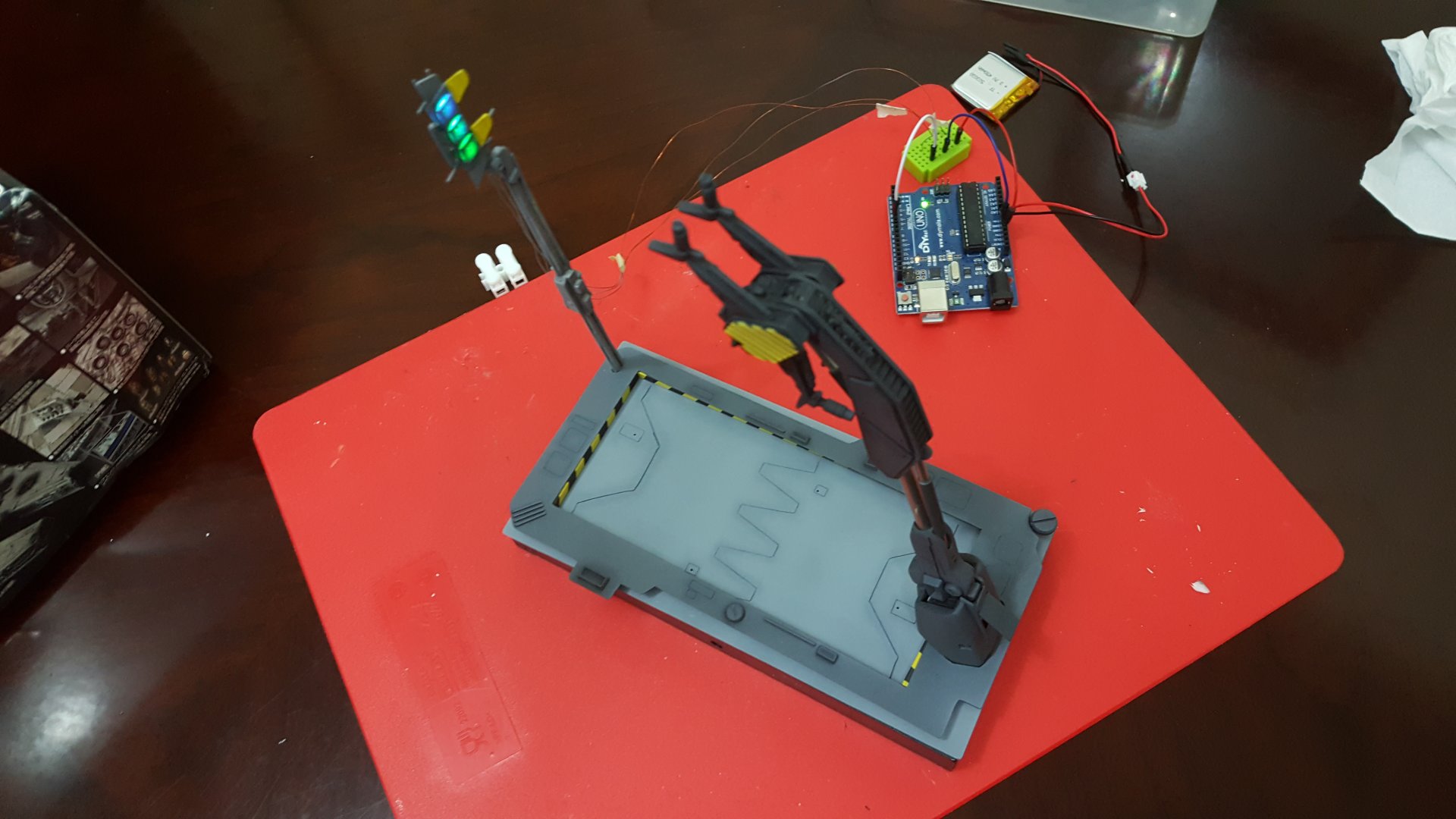

Note that the launch arm is not yet glued together. I have 17 wires that will run from the valk through the launch arm down the 5mm copper tube. There is plenty of space, but wires dont travel at right angles. So permanently gluing the claws is a last step.

-

No that's my kids' 1/44 Bandai. I refuse to do a Falcon until they make a 1/72 with opening interior like the one I grew up with. Can it be so hard?

-

-

That's why you need the big saw. Cuts through the resin like butter.

-

In that case, you definitely need a razor saw. Classic Japanese tool. They cut in reverse stroke and are very thin.

-

Oh boy. Safety first every one.

-

Brett is right. But don't drill wet, because then you have other problems

-

Uhhhhh, yeah... I've watched that doggy walk right off the edge every time.

-

Derex, sounds like you could also use some Tamiya razor saws, the big one and little PE ones are great for removing big chunks safely. And I forgot to mention, wear protective glasses as well with the Dremel; I've had several bits break and fly off who-knows-where.

-

How do you keep them from sliding off the rubber thingy?

-

You also need a set of Chinese diamond file bitd. I hardly use the Dremel bits. They are too strong. And I dont give marriage advice, but trust me you will have a lot of modelling time when youre "not needed" around.

-

If you cant wait on shipping, I believe there are alternatives to the WeCheer at your hardware store that are low speed grinders, sometimes used for nails, sometimes battery powered. But I can only recommend this one because I have had it for months and it rocks.

-

DO NOT use your Big Daddy Dremel on your expensive model.

-

Okay, some advise, you use these grinders mostly from the side of the bit to shave delicately. You don't use them like a drill, unless you're trying to gouge something out.

-

The Dremel is too strong for that. It's like a bucking stallion. But this one can do delicate work and you can control it.

-

Derex, So you don't cut yourself again, I recommend the WeCheer low speed grinder on Ebay. It does really fine work for shaving and sanding, and you can keep the heat down as well. It uses the same drill bits as the Dremel. I use it for carving, cleaning photo etch, and removing nubs on resin and plastic. You still need the adult Dremel for drilling holes and serious carving, but with this you never have to shave with an Xacto again. Remember to always use a gas mask when grinding resin AND plastic.

-

This one is for you NZEOD. You taught me everything I know about this stuff. I'm just the sous chef. Best wishes for your daughter.

-

-

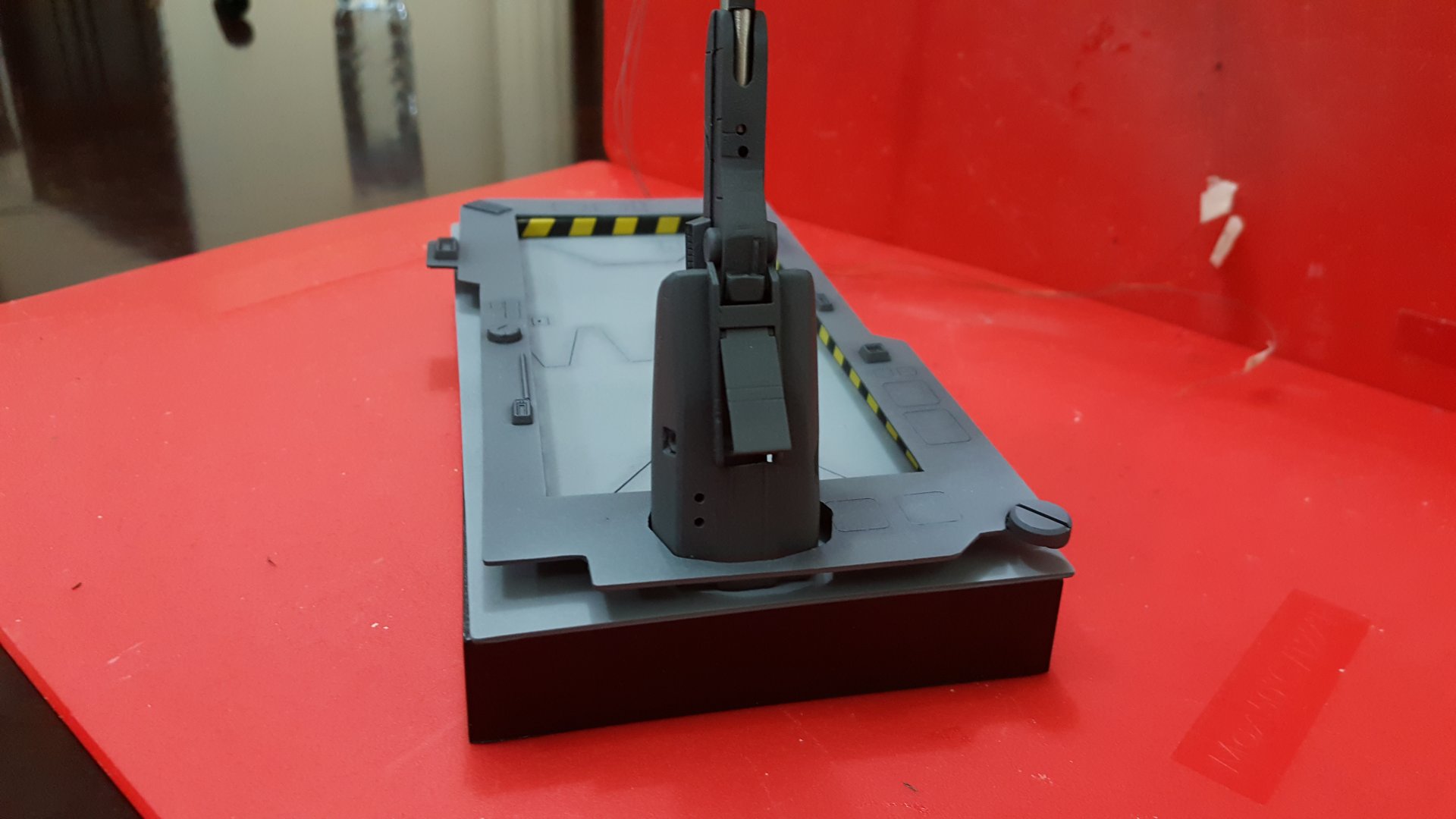

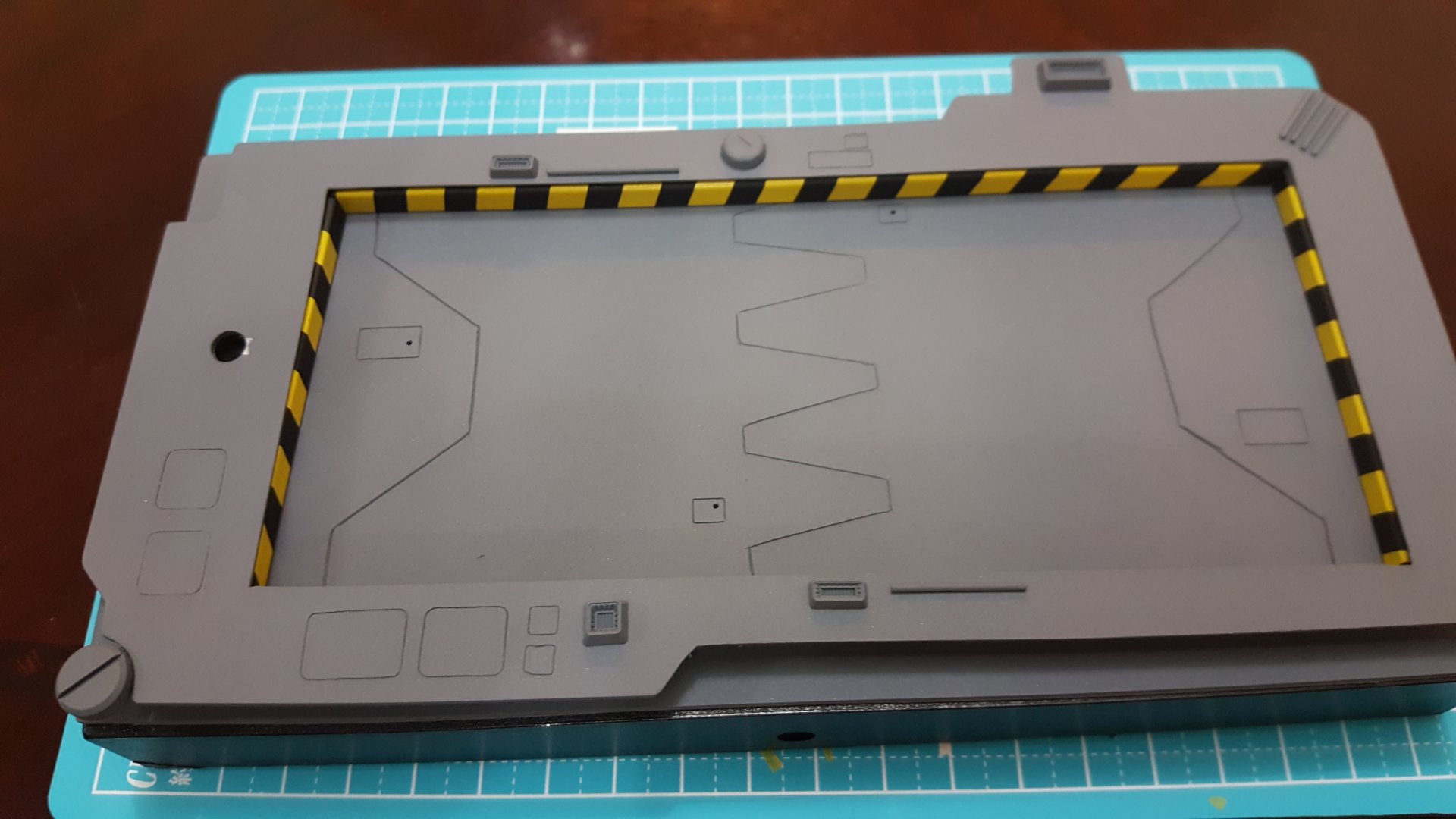

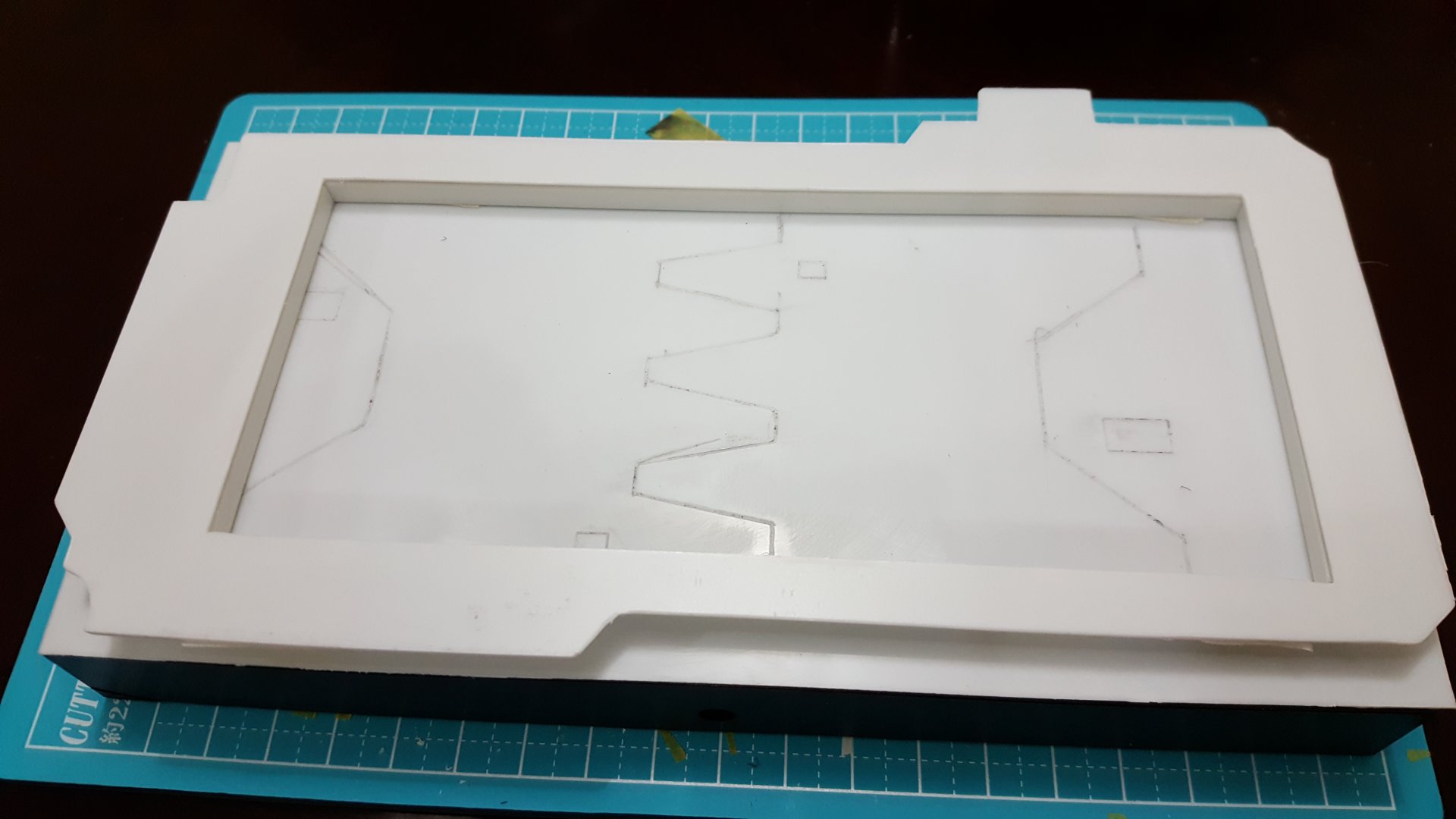

Working on the ARMD base. I'm using a black LED display box from ebay, which I retrofit for my electronics (20cm x 10cm), and the top is just styrene sheet and rods.

-

The Ranger! Because I can't afford the Kids Logic Cockpit Speaker. Those are the Jasmine PE parts for the screen.

-

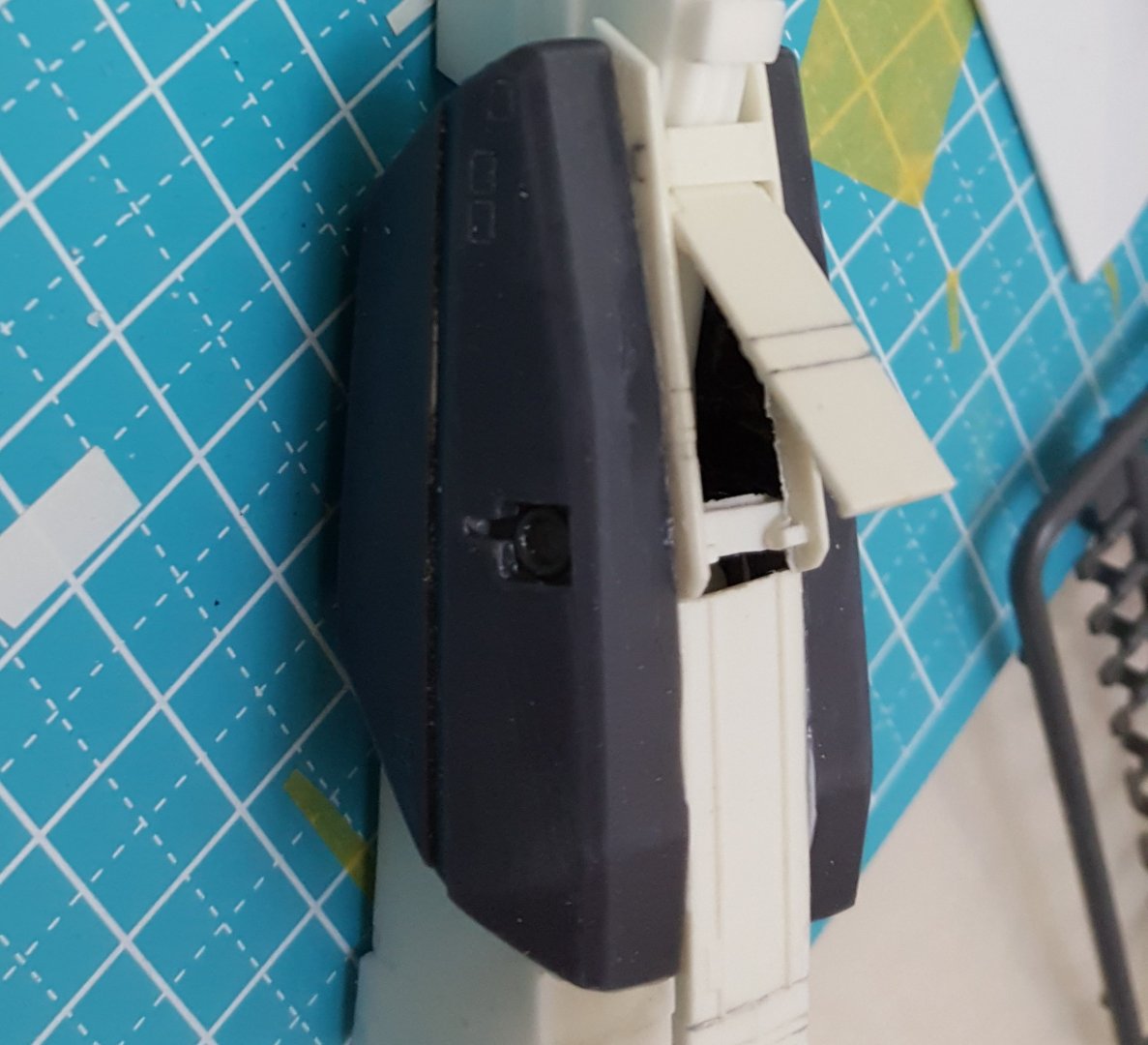

I got Aber PE hinges to try out. These little guys are nearly impossible to work with. But I think I got it on pretty strong with a needle drop of epoxy to hold, then after it cures, more generous amounts around the edges.

.jpg.62bdcef2e99bd8c206337f974e2afa91.jpg)